Using Foam Board to Insulate Walls Without Sheathing

I’m working on a renovation / addition to a home built in 1896 in New Orleans. We’ve basically kept only the facade and foundation. I will be sealing all the new walls up tight and have an unvented attic and crawlspace with dehumidification.

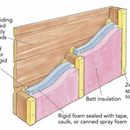

My concern is insulating the old facade. It’s beautiful old weatherboard cypress siding. I want it to last another 120 years and I do not want to do anything to diminish the ability for the old wood to be salvaged at some point in the future. I understand I need an airgap to allow the siding to dry out, and I’ve found the diagram in the attachments that calls for 1″ foam board furred out 3/4″ for an airgap. Then fiberglass batts are installed after adding 2×2 spacers.

The framing is true 4″ studs so can I use 3″ ridgid foam board furred out 1″ for the air battier so that I do not need to extend the wall an inch and a half? I would then seal the joints with caulk and/or flashing tape. That would give me R-15 without having to extend the wall.

Are there any potential problems with this method?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Cut-n-cobble makes a questionable air barrier. Consider a high perm interior side membrane (not a vapor retarder) or drywall detailed as a second air barrier.

OK I was planning on trying to get it flush with the stud to apply some leftover zip tape to the seams as a way of increasing the air sealing.

For the membrane, do you attach the it to the studs right before drywall? Or wrap it in and out of the stud bays before the insulation? Or would a drywall gasket be a better solution?

thanks

All three sound possible - I don't know which would be best.

+1 on using open cell spray foam instead of batts.

Deleted

It looks like you're basically trying to build a rain screen from the inside. I don't really see a problem with your proposed assembly. I would absolutely use polyiso here, especially considering your Southern climate zone. This might be a good place to try using reclaimed polyiso too, save a little money that way. I would seal the edges with canned foam, or caulk if you can get a really tight fit (which is surprisingly difficult to do in practice, BTW). I would skip the tape.

A vapor retarder membrane would go right against the studs just before the drywall goes up. You basically staple it up, and seal the edges (I use urethane caulk for the sealant here). Drywall goes over that. I typically put a bead of sealant around the perimeter of the wall immediately prior to hanging drywall too, just to make sure there is a good air seal. I have no personal expierience using drywall gasket material.

I agree w/ Jon that cut'n'cobble rigid foam isn't always a good long-term air barrier, so it makes sense to put a backup air barrier somewhere else in your assembly. This might be one application where open cell spray foam would be a good fit, you could even use some thin 1/4" hardboard as a backer to form your air gap for the siding, then fill the stud cavity with open cell spray foam for your insulation and air sealing layer. I don't normally recommend spray foam in walls, but it might make sense for your specific application.

Bill

Thanks for the reply. I think I'll stick with the foam board and add the vapor membrane. I salvaged every piece of framing from the house and milled it into heart pine flooring. I don't want to ruin the wood with foam.

But speaking of foam in walls...why do you not recommend it? I was planning on using Rockwol, but it has a 4 month lead time right now. I've decided to go with open cell in the walls. Is there a better way?

I'm a little confused by your post, since it sounds like you want to "stick with foam board", but also "decided to go with open cell"? Rigid foam board, which includes polyiso, EPS, and XPS, is certainly going to be less messy to work with and have no risk of overspray in the way spray foam does. If you go with open cell spray foam, I'd put TAPED ram board down on your nice floors to protect them. Spray foam is VERY difficult to get off of anything it in comes in contact with.

Regarding rockwool, have you checked with all the manufacturers of that product? A lot of people think "Rockwool makes rockwool", but mineral wool is also made by Owens Corning, Johns Manville, and probably others I'm not thinking of. I've seen Johns Manville mineral wool in stock in my area, and probably Owens Corning's version too. The products are all pretty similar between different manufacturers.

The reason I don't normally recommend spray foam in walls is that the thermal bridging of the studs negates much of the performance advantage spray foam would otherwise have if it was applied in a continous layer. The advantage to spray foam is that it will generally double as an air barrier, and it will seal everything, so if you have a special application where air sealing is vital and difficult to achieve with other methods, spray foam can be a good fit even if you're not using it for an R value advantage.

I personally usually use exterior rigid foam and mineral wool in the walls. I see no reason your wall wouldn't also work like that, with mineral wool over the rigid foam panels, you'd just have to make sure you have a good interior side air barrier. I'd recommend polyiso as your rigid foam material here because of it's R value per unit thickness advantage over the other types, and in your warmer climate zone the "polyiso R value drops in cold weather" issue isn't really a problem.

Bill

I apologize for the confusion. I meant that my plan is to spray foam the new walls- not the old facade from my original question.

Thanks for the info. I’ll keep looking for mineral wool, but I can seem to find any brand in stock anywhere. I should have added the foam board on the outside wall, but the space between my house and my neighbors is only about 25” and I learned about that method after it was too late. So I guess the foam would be best for sealing.

You could position the air barrier (vapor retarder membrane) directly against the old studs, then do the 2x2 over it and fill the new "stud" bay with a loose fiber mat, then drywall. The 2x2 could even be run in horizontal way to better run cables without having to penetrate the air barrier. Even if some air sealings "old stud - EPS plate" do come loose after a time, the air tightness is still maintained