Bonfigioli wall and slab

I have been wracking my brain trying to solve a problem and this mornings post on the Bonfigioli wall may have provided an elegant solution. I am designing a house for my son and daughter in law in Pownal, Maine. They want a slab. We are starting with a wee little 400 sf house that will become part of the larger house in a few years. Outsulation makes the most sense but is a cost factor. Insulating inside the frost wall made it hard to cover the thermal break at the edge of the slab and left me feeling that the top of the concrete wall after notching for the slab and rigid made for a weak wall (4” wd x 6” high). Then there was still a thermal bridge at the sill.

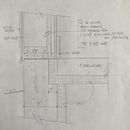

The solution in the attached drawing gives me a 6” wide concrete wall at the top, the rigid thermal break is covered and the wall is R30. I’m showing using 1×2 instead of 1×3 as shown in the FH article. He was making up the strips with strapping ahead and adding them to the wall in one piece. It left gaps that had to be filled with foam. 1×2 eliminates this but tell me if there is some reason why I should use the 1×3 as he did.

I have three more questions.

1. How does the vapor barrier on top of the rigid pass through the sill area and connect to the air barrier? I have seen examples where it wraps up over the bottom of the sheathing and is taped to the outside of the sheathing. My concerns are that over time the seal will be lost, water gets behind the vinyl siding and is pooled inside the bottom of the poly and rotting the bottom of the sheathing.

2. Does it make sense if the budget allows to add another layer of rigid below the slab or inside the wall? The vertical insulation goes down to the footing. The thermal break at the edge would remain 2”.

3. Are there any problems you see here.

Thanks for your help.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Hi Brewer, I have a renovation going now in Pownal and gearing up to start a couple more. Your detail looks pretty good. The vertical insulation below the slab isn't doing a lot; it will help keep the area below the slab warm, but I'd rather see at least R-10 and preferably closer to R-20 directly under the slab. I usually spec 5" or 6" EPS.

I like to wrap the sub-slab vapor barrier over the top of the foundation wall, sealed to the face of the sheathing with Siga Fentrim tape. I understand your concerns about the potential for rot but Fentrim sticks very well, and it's vapor permeable so if a little moisture accumulates it will dry out. If you want to go above and beyond, you could tape the vapor barrier to the face of the foundation and then tape the sheathing to that. You'd have to run the siding down a bit extra to cover.

I usually make the top portion of the frost wall 5" wide, with a 3" shelf. The IRC says the foundation wall needs to be at least as wide as the wall it's supporting, but I've never had pushback on a 5" wall with 2x6 above.

Will the bottom of your footings be at least 48" below grade?

Brewer,

1. The vapour-barrier doesn't need to be continuous with the exterior air-barrier. You just need to seal the bottom of the sheathing to the stem-wall with tape or sealant. If you don't trust tape, then Zip is the wrong sheathing to use, as it relies on it for all the horizontal joints between sheets, and head-flashings.

2. I agree with Michael.

3. No, it looks good. However, although Bonfigioli walls perform well, they are very labour intensive, and only make sense if you are doing the work yourself.

Thanks Malcolm. The “kids” and I will be the labor for the Bonfigioli wall. They are willing and it will do them some good to have skin in the game on their build.

Brewer,

It's a good system. You will need to modify the standard framing details for inside corners, and wall intersections, as well as how to attach outlet boxes.

Good luck with your build!

Thank you so much for a quick reply Michael. So if I was going to tape the vapor barrier to the foundation would I use Siga Fentrim tape there as well? The footing will be 48” below grade. Are you suggesting then to eliminate the vertical insulation on the frost wall if adding more under the slab? If I do that and my notch in the concrete becomes 2”wd. X 9”h. Will I need to put some rebar in that 6” wd. X 9h. Part of the wall? This first little house is one story but the rest of the build in a couple of years will be 2 stories and I’d like to use the same detailing for both. For nearly 30 years I made working drawings for homes in So. Maine. I left the industry in 2011 and I admit I have some catching up to do. It’s wonderful to finally see the new shift in materials and techniques. The plan is to get a contractor to get the shell up and we’ll take it from there handling the interior air sealing, insulation and vapor barrier so we can be fussy about it. The only good thing that Face Book ever did was that PGH kept showing up in my feed. Thank you. :)

Yes, Fentrim is good for that as well. It's available in a gray color that is similar to concrete, from Performance Building Supply in Portland (or sigatapes.com).

I usually just put one horizontal #4 within 12" of the top of wall and one at mid-height. You could add vertical rebar if you want but I've run this detail by structural engineers several times and I can't think of a time they have required the vertical rebar, though of course they always like more steel. We're in a pretty mild seismic zone which would be the main concern for tensile strength at the narrow part of the wall.

I'll attach a screen shot of a similar detail I just did for a project in a warmer climate zone, but it's a similar detail, except with Zip-R sheathing instead of the Bonfiglioli assembly.

It is interesting how much has changed in the industry in the last ten years! And we're lucky in Maine that builders and suppliers are at least familiar with the idea of high-performance techniques, which still seem to be as unusual as a Yeti in some parts of the country.

That is a good use for Facebook!