Blocking Thermal Bridge at Garage Doors

Hello All – I hope that you are all having a great day!

I’ve read through some threads and absorbed some of the recommendations related to dealing with thermal bridges where interior, heated-space doors (dwelling/garage) meet up with cold air.

2″ XPS under slab and vertically around entire perimeter.

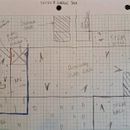

I am thinking of moving the joint that would normally be near, or under, the garage door back in to the garage a few inches (8″ or so). Having that joint inside facilitates the installation of the vertical XPS; thus breaking the thermal bridge. That would allow me to protect the vertical, 2″ XPS from water intrusion — by having it in the garage. But brings up, among other things, the question of whether the cold part of the driveway slab that is now inside the garage (see atch’d pictures) will radiate in more cold. Would there be radiated heat out through the driveway slab being in open air than there would be through direct heat conduction to the outside if the vertical XPS was not installed).

All that to say. Does the proposed solution negate the heat improvement by adding the R10 XPS — over the R0.1 of conc.?

Thoughts….?

Related Threads:

https://www.greenbuildingadvisor.com/question/thoughts-on-slab-insulation-detail-at-doors

https://www.greenbuildingadvisor.com/question/door-thresholds-for-insulated-slab-on-grade

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Ok I was curious about this so did a quick calculation on heat loss, please others correct if wrong. U-value 2” concrete=5, 4”x10’ section, 70 degree difference in temp= 5 U*3.3SF*70= 1155 btu/hr. That was a lot more than I expected. Obviously that is a very simplified calc, but any way you look at it will be large. For comparison eps in that space is something like 25 btu/hr.

Does my calc make sense?

Deleted

Freyr_D,

If I am understanding your simplified calc....

Even with the vertical XPS install and moved 8" to the inside, for every 10 foot section of interior slab along that 8" setback we are releasing 1,115 btu/h of heat to the other side of the door?

I'm adding a couple of more pics.

1. Section at Garage door with no vertical XPS (heat conducting out along each opening)

2. Overhead at garage door with no vertical XPS. (mostly to add door widths).

I was just looking at if there was insulation at door line vs not. That was also assuming a 70 degree difference across the two inches which is very high, both in terms of outdoor temp as well as temp gradient in slab. Still it seems high, and also high in ratio to eps

EPS = expanded polystyrene?

When I think about it, I think about whether the 8" or so of unheated slab, that is exposed to the heated floor at the interior and to the cold on the exterior, will have more energy siphoned to the outside than I am saving by 1) even including XPS or 2) having XPS under the door exposed to weather/water. See images atch'd (picture = 1k words).

Is my thinking in line with your calculations?

I would either do nothing or put it at the door. If I put it at the door I would not leave the wood as the top layer. I think I would taper it slightly and then leave it maybe an inch or half an inch low, then fill the gap with either, a heat set crack filler like pli stick that you fill and torch to liquify, or a concrete polyurethane caulk. The other option you could consider is concrete epoxy and the very top, as that stuff has like a 60k psi rating and probably better thermal than concrete.

The wood is a bad idea though as you want to be completely water tight, otherwise you will get water freezing in there and have heaving.

Yeah, PT lumber never really sat well with me. That is why I started looking into alternatives (move the joint back OR use some sort of composite material as a cap).

From the specs on some of the sealants it appears as though a minimum and max gap applies. I suppose it is to facilitate good adhesion (1/8 - 1/2 inch).

Any suggestions on how to keep the gap/joint at the top so it can be filled later?

Also, wonder if it matters if the vapor barrier goes on the apron-side of the vertical XPS or on the garage side (as in atch'd image).

I am checking on details of Pli-Stix, Simpson's Crack-Pac and Prosika's Self-Leveling Sealant - among others - for a sealant.

Thanks

WD

Reply to #9:

The vb should be on top side of XPS under slab, follow vertical like you have it, you could then tuck it over top of XPs down other side slightly.

The caulks have a max fill width because as they dry, they contract, and the wider you go the more force you get on contraction. That is why you conclave them when you are doing joints on things like curtain walls. I would just make the gap somewhere within their specifications. If you coupled it with something a bit more rigid like the pli stix or epoxy I think it would work well, but I’ve never tried it.

Also note, XPs burns like crazy so if you do the pli stick you might want to protect foam with thin layer of sand or something.

I would not worry for a second about water intrusion damaging the foam. They use XPS for dock floats. AS mentioned there a re a number of products that can seal it anyway. Biasing it 1/2 inch inward would mean there should be little bulk water touching it

Thanks Gusfhd - I thinking more of the water getting down inside/under the slab/foundation. But with the suggested sealants I think I'll just leave the joint at the door/stem wall.

I did 2" vertical XPS lined up under a 12' wide exterior overhead door. The top of the xps is tapered at a 45 degree angle. The bottom of the XPS is dug into the compacted base below the slab about 4 or 5 inches. The interior portion of the slab has horizontal insulation. The slab is a 5" thick industrial floor with radiant heat. Zone 5.

The thermal break works exceptionally well, better than I expected. On a below freezing day the slab just inside the door does not feel cold to the touch.

8000 lb forklifts roll through the door daily. A crack developed where the top of the xps tapers to a point (under the door gasket) which was expected. The crack could be caulked if aesthetics were an issue.

D_hallowell,

How deep is the that top edge on the 45 degree below the surface?

Thanks Man!

The top edge of the foam was used as a screed line while pouring the slab, so it's just below the surface. Maybe 1/4 or so.

You have to be gentle with the vertical foam when pouring. Shovel concrete on both sides to build up the height. Don't dump on it with a pump hose or wheelbarrow.

idahobuild,

There is nothing magic about the taper being 45 degrees either. If you are worried about the strength of the concrete there you can make it 60 deg.

Thx guys. I'm going to talk to GC about this.