Basement rigid foam insulation – air gap

I finally found some time to start renovating my basement.

It has all the framed wall but no insulation.

In the past I had the pink batts + 6mil but had some rot problem from an outside leak which is now fixed.

I was debating between Roxul or Rigid board and finally choose the later.

The best would be to spray but I won’t take the risk with the VOC that can happen with the actual lack of qualified worker.

For my Rim joist, I put 2x layers of 2in XPS with 1/2 – 3/4 in gap and filled with expanding foam.

I also made sure that there is always a minimum of 2 in foam on the top face of my concrete wall touching the foam of my rim joist to my framed wall.

For my walls, the first 2 in layer of foam is touching the wall and I made sure that all the seams are sealed with blue tape. Now the electrical wires are between my first layer of foam and the back side of my framed wall studs.

When it is possible, the second layer of the 2in foam is 100% touching my first layer of 2in foam.

However, if there are restrictions such as wire, gas line, etc.. I gently pushed the second layer until I touch the wires/gas line and then seal the contour with expanding foam.

The contour of my bays and the back side of my studs are sealed with expanding foam so there are no thermal bridging.

My question for the group, do you think the 1in air gap between the first and second layer of rigid foam (when there are restriction such as wire) will cause any trap for moisture, water vapor?

Personally I do not see how moist air can travel there, unless it is being transferred in winter from the inside thru the drywall and then thru studs (unheard of).

Or in summer from the outside thru the concrete wall but I have 2 in foam so basically it is like a vapor barrier.

I live up north in Canada, but where I am is Zone 6 compared to USA climate map.

Give me your input

Photo 1: First layer of foam

Photo 2: Second layer of foam, you can see upper section is touching the first layer, the bottom section is touching the electrical wire with a gap between the two rigid foam.

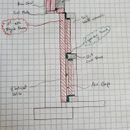

Photo 3: Sketch cross section

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I would avoid the air gaps as I think they are asking for problems. What I would do where you have a pipe in the way is notch out the rigid foam around the pipe, then fill the void with canned foam. I would do the same for wires, but I would NOT bury the wire -- try to only cover the wire where it goes behind something you can't move, then keep it on top of the last layer of rigid foam the rest of the time. The reason is that you really don't want to bury electrical wires in thermal insulation, since the insulation limites the ability of the wire to cool off.

The reason the air gaps are a potential problem is that the seals you make tend to not be reliable over time. This is why cut'n'cobble isn't a good idea in a roof, for example. You may well find that those air gaps don't give you any trouble, but I think it would be safer to avoid them in the ways that I've described. Ideally, you would have ALL of your insulation as continuous rigid foam against the masonry, then build the studwall out over the rigid foam so that the wood framing never contacts the masonry directly. I think in your situation that framing is already there, so you're limited in your options, which is why I recommended cutting the foam in around pipes and filling any gaps with canned foam instead.

Bill

Hi Bill,

Thank you for the reply.

The first 2 in layer is continously and 100% sealed on the edge lap joint with blue tape.

The second layer is cut and cobble between the stud bays. There is a 3/4 in gap on the width and height.

The gap was filled with Great Stuff Pro expanding foam.

Do we have any data that the expanding foam (which is creating the perimeter seal) will deteriorate over time? Are we talking 10, 20, 50 years?

Thanks

I'm not aware of any formal studies as to the longevity of canned foam, but there is empirical evidence that it can "let go" over time (seperate, probably due to expansion and contraction, as well as shifting, of the structure), and some have mentioned deterioration to dust. I've not seen it turn to dust myself, with the one exception of when it's left exposed to sunlight, which WILL cause it to degrade over several years. I HAVE seen it seperate before though, which usually looks like a crack. I think overally it's a pretty decent way to air seal, but make sure that it's in gaps and not on surfaces (where it's much more likely to seperate from the surface). Canned foam really needs to be used in gaps or holes where it can "go deep" and expand against surfaces all the way around to lock in place. Most of the failures I've seen are shallow cracks and things like that where the canned foam couldn't really go "inside" to expand and form a compression seal. You really need to use caulk for smaller cracks and surface defects, canned foam is best for larger holes and gaps.

Bill