Basement insulation – how to handle gap between EPS and fiberglass bats

I am working out the details of (re)finishing my basement in a late 1950’s home with a poured concrete foundation in zone 5. I’m planning on putting 1.5″ EPS rigid foam on the exterior walls, building 2×4 walls just inside of that, and insulating between the studs with R-13 fiberglass insulation.

One issue I have run into and a couple questions:

One long wall has a vertical slant in the foundation wall so that the bottom of the wall bows out to the interior. I suspect this is from the (handbuilt) forms bowing out when they poured it. At the worst point the bottom is ~3 inches further into the interior than the top; this bowed out area spans at least 15 horizontal feet.

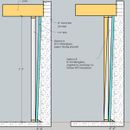

Question 1: should I put the fiberglass in the stud bays as normally done and have an air gap between fiberglass and EPS at the top of the wall? (Option A in the attached picture). Or, should I place the fiberglass so it follows the EPS to minimize any air gap between them? (Option B in the picture)

Question 2: Even with the better non-slanted, non-bowed walls there will be some gap between the framing and EPS since even these better walls are far from perfectly plumb or flat; I’m guessing that gap may be able to be ~1/4″. So even in this ideal case there could be some air gap, should the fiberglass be attached as normal with a probable ~1/4″ gap between it and the EPS?

Question 3: the little triangle at the bottom of the foundation wall really is there. Should the EPS go down to the slab and cover it? Or end a couple inches above the slab, above that little alcove?

I’m in a fairly arid climate, not too much worry about natural groundwater. The biggest danger is a hose or sprinkler left on or malfunctioning.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies