Basement Insulation for Mixed Concrete & Stud Half-Wall

I have not found an explicit answer for how to insulate a basement wall where the bottom is a concrete form and the top is existing 2×6 framing, so wanted to seed the options I have come up with and ask for feedback.

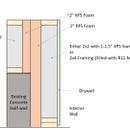

Minimally, I am planning on putting 2″ of XPS across the concrete half-wall portion and then would frame out a 2×4 interior wall in front, with mineral wool filling all the gaps. However in that config I was not 100% for where to put the vapor barrier given the foam is only on the concrete section. I show two possible positions in the graphic included. Logically, position (1) – keeping it on the internal side of the existing framed wall and then taping it to the XPS foam – makes the most sense, but then is there a limit for how much insulation can be internal to the vapor barrier?

The alternative is to just remove the existing vapor barrier on the existing framed portion and then bring XPS all the way up to the ceiling (and frame out the wall to be even with the concrete half-wall or pack that gap with 2″ of more foam). But as I write that out, that seems more complicated and expensive.

Both of those options are shown in the attached images.

Core Question: Is there a preferred path (between these two or something I am missing and a new one option to consider)?

Finally, the floor is slab on grade concrete, and I am leaning towards DriCore Subfloor R+ (https://dricore.com/products/dricore-subfloor-r/) to balance the thickness / height issues I am working with – if there are suggestions here, I am all ears too!

Note that I am climate zone 4C (Marine), i.e. Seattle area. Thank you in advance for your time and input!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

ntrail,

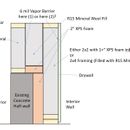

I would only use foam board against the concrete (option #2). I would run the vapour-barrier on the outside of the interior stud-wall from the top of the foam. If it is poly, you don't want it on the interior of that wall because it will block the drying path of the wall to the inside. You also don't want it on the inside of the exterior wall as it is too close to the outside and may get moisture condensing on it.

Thanks for the reply! To confirm, all options will have foam against the concrete, but I think you are suggesting the following (per attached image)? Where I put down a 6+ mil vapor barrier on the exterior facing surface of the internal non-load bearing 2x4 wall, and tape that to the XPS - checking? If so, should I also leave the resulting ~4" gap above that XPS foam empty or fill with mineral wool and then put the poly on top of that? (probably easier and more stable versus taping it only at the top of the framed wall).

Also is there a recommended tape to transition from poly to XPS?

ntrail,

I would fill the void with mineral wool.

You have a couple of choices for how to attach the poly to the foam. It can be bedded in acoustical sealant and then needs a few cap-nails to keep it from moving. Probably easier is just to tape it.

One mildly crazy idea here is to put the vapor barrier underneath a caulk-sealed 2x4 with some screws into the XPS or concrete wall on the back part, and then with mineral wool on top - see graphic - basically no reliance on tape at all then. Overengineered but viable?

Deleted