Barrel Vault Ceiling More Economical Than Flat ?

Looking at framing a room with 23′ clear span and 30′ long as a great room, it seems that even with only drywall ceiling and attic insulation as loads, the ceiling joists would need to be 2×10 at 12″oc to get even L480 deflection limits. That seems like a lot of expensive lumber for a ceiling.

So I wondered why the Roman arch is not used. 2×8 joists kerf cut every 10″, glue in the cuts and then ratchet strapped while it dried would turn a 24′ 2×8 into a seriously (24″ deep) crowned ceiling joist. Because the load would all be in compression trying to push out the sidewalls instead of as bending stress on the middle of the ceiling, it seems like 24″oc ceiling joists would be rock solid at 1/2 the cost of the 2×10 prescriptive design that would actually sag 1″ at L480.

Yet I can’t find any info on modern use of barrel vault curved ceilings that are anything more than decorative, much less actual span tables with plf numbers. Why is that ? It seems like the value of the structural arch has been lost to residential light construction.

Thanks,

Kirk

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

As you say, your walls would tip over…. Also that sounds like a ridiculous amount of work.

Rafter ties at the base of the roof would already hold the walls together, so the push out on the walls shouldn't happen. Even if each joist needed its own 2x4 tension tie across the top to hold the walls,it would cost half as much as the 2x10 flat ceiling.

As far as labor, it doesn't seem like much work to clamp 17 2x8s together with wax paper between on sawhorses to gang cut them, make a pass every 10" with a skilsaw, run a bead of glue into each kerf and then tighten a ratchet strap. Sounds like 20 minutes work. Maybe stack bags of cement or other lumber on top and let gravity pull the kerfs together instead of ratchet straps. Leave them overnight to dry.

It would save $1000 on this size ceiling and each joist would be lighter and easier to handle with 1/2 as many to nail in place, so it seems worth the time to kerf bend them. My gut says deflection would be better but I can't find any data on it. If anyone know where to find data, please share!

I used to do a lot of curved work when I was a carpenter. Even with practice and systems, it never takes less than twice as long as doing straight work, and often it's 4X or more effort. You will absolutely not save any time over using conventional techniques. The 20 minutes of work you describe is probably more like 2 hours at least, including setup, breakdown and cleanup.

It sounds like you're committed to your idea, so go ahead and try it! It can be fun to make curved shapes. It's just slow.

I don't understand what you're describing, though. You mention including rafter ties in your comment, but in your post you said you were trying to avoid rafter ties. If you want to share a sketch of your idea it would help us understand what you're imagining.

I'm not committed to this idea, I am exploring least-cost ways to have an unsagging ceiling that clear spans 23'. I am open to suggestions to accomplish that.

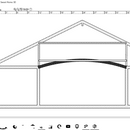

Sorry if I gave the impression I was trying to avoid rafter ties. I am only talking about the ceiling of a single room, and the roof is a separate structure. The ceiling joists would not act as rafter ties, but there would be rafter ties above in the attic. I added a ketch to my original post.

This home would be 48' wide on the gable ends, with the 23' wide center great room with the proposed barrel vault ceiling and 11' wide rooms for a master bedroom on one side of the great room and two small beds and bath on the other side. The 48' wide roof would sit on top with a ridge beam, 6' tall attic walls at the rafter midpoint, directly over the great room side walls, with the rafters and rafter ties meeting on top of them. So there would be rafter ties holding the walls together 6' above the attic floor, 4' above the top of the curved ceiling joists. If that was too far, a second tension tie could be directly above the ceiling joists locking those 6' tall attic walls together.

You've built with lots of curves ? Using the kerf method or all the jigsaw cut curves into plywood or dimensional lumber. Or varying width sleepers and bending furring strips ? All that plywood cutting and sleeper calcs does sound like a lot of work to me. And non-structural from what I've seen.

My goal is not to save time, but to use less lumber, have a stiffer ceiling, and save some money, since my labor is free. I could, after all, have a flat and stiff ceiling with the joists hung from a $2000 lvl beam. Or I could spend a similar extra amount using tji's for ceiling joists, or pay $80 each for 2x12s at 12"oc. Lifting a 32' double layer 18" lvl into place would be an issue to do alone, the cost seems unnecessary, and I would have an ugly beam running down the middle of my ceiling, etc. I could have an engineer design a box beam to span 32 feet at 300plf to go in the attic and suspend the ceiling joists from it. Lots of things I COULD do, but if a beautiful curved ceiling is actually the least expensive and stiffest ceiling to build, with all elements being light and easily manhandled, then I'll do that. I just need to know where I can get numbers for what appears to be an unusual solution. If an inspector just decided all those kerf cuts were illegal notching of bottom edge of the joists, I think that would be ridiculous, but most inspectors are not engineers -- so I'd need some reference material, engineer's stamp, etc. to fall back on.

I think you are underestimating the outward thrust. I just did a quick calculation ( I am not an engineer but you can do you own math to verify.) and came up with (edit, I read 32' not 23' originally) 991 lb outward thrust at every arch member with the following assumption, 15lb ceiling load, spaced at 24" o.c. and a 24" arch height. The formula is Ha=wL^2/8f where Ha is outward thrust, w is lb/in, L is length in inches, and f is height in inches. this would be in addition to your rafter thrust, and your rafter ties are not at your plate, which introduces a bending moment in your rafter. This all seems like a bad idea to me, there is a reason buttresses and gothic arches were invented.

also you don't need L/480 for a ceiling

Lastly, this is on each side of the arch....

I guess I am displaying my ignorance.

First, the top portion of the roof IS a simple triangle truss with a 2x4 bottom chord and 2x8 rafters, so you are claiming a 24' wide truss won't work because the bottom 2x4 bottom chord can't provide enough tensile strength to resist the side thrusts of a roof ? Since the majority of roof trusses only have a 2x4 bottom chord, that doesn't make sense to me. The rafter tie IS at the bottom of that roof portion because it is supported on side walls and not simply rafter ties in the middle of unsupported rafters at midspan like would be the case without the attic kneewalls. Besides which, the ridge beam is structural, not just a ridge "board", so it alone would eliminate almost all outward thrust from the roof rafters.

Second, I have a hard time believing 2x4 tension ties down at the level of the ceiling joists can't handle the outward thrust from the ceiling. If they can handle the thrust from a roof (without any structural ridge beam) that is more heavily loaded than a ceiling, then why wouldn't they be able to handle the outward thrust from the ceiling ? I don't doubt your thrust calc, but isn't the tensile strength of 2x4 doug fir something like 5,000 lbs ? True, the thrust is all at what would be a hinge point between the attic wall and the wall below, but the second tie is only 2' above the hinge and could be sistered to the curved ceiling joist for the center 2/3rds of the span if it would help.

Third, manufactured truss roofs are less than 100 years old. Before that, all roofs were either rafters and beams and purlins or ... arches. So there must be a way to triangulate the rafters and attic knee walls without using manufactured trusses, right ? Stick built roofs are done every day, after all.

Fourth, my understanding of deflection must be wrong. I always thought it meant that the diaphragm would sag by the span divided by the rating. So a ceiling that was 20', or 240 inches span, would sag 240/L240=1inch at the middle when fully loaded. I consider an inch or even a half inch sag to be unacceptable in a ceiling. So I always look at the stiffest rating in the chart, L720, even more for ceilings than I do for floors.

A sketch would be very helpful. I know it's clear to you but it's not clear at all to me what you are describing.

Code-minimum deflection for ceilings is usually L/240, or L/360 for brittle finishes: https://codes.iccsafe.org/content/IRC2015/chapter-3-building-planning#IRC2015_Pt03_Ch03_SecR301.7. You can certainly exceed that if you want but I only use L/720 for floors with large-format tiles. I have learned from professional engineers to limit deflection to 5/8" in most cases, which can result in stiffer floors than code minimum.

The whole point of a truss is to place all members in either tension or compression. when you say your top portion it is a simple triangle truss this is kind of true but a bit misleading because you are also dealing with a bending moment in your rafter because it is unsupported like you would have in a normal truss.

1. I am not saying the bottom member can't resist the outward thrust, I am saying you are introducing a bending moment into your rafter wherever that attaches. This might not be an issue, but It may be an issue and this is why you need to calculate it. Also from your drawing, you have a bunch of potential hinge points that I don't think you understand how all the forces will be balanced, which is why you need an engineer. For instance, where the arch is pushing out on that wall, is that a balloon framed wall? or is there a top plate there? and then the arch is pushing on the member above, which creates basically a lever out of that upper member?

3. No one was building arched wooden roofs, especially on stick framed walls. Arched structures were almost always stone or concrete and they employed some strategy to counteract the outward thrust. for instance the pantheon has 18' thick wall, and the notre dame has buttresses. Even the wooden roof of the notre dame was built over a stone arched ceiling. And just because manufactured trusses were introduced in the 50's does not mean we were not using trusses much before this, they were just site built. look at any rail bridge, they are, at least in united states, mostly truss structures.

4. that is what deflection means, but a couple of things to note, 90% of the time you will not be at your full design load because you wont have a live load up there. this means that most of the time the deflection will be much less than what you are suggesting, and if it is live loaded, you just need to make sure that the ceiling gyp doesn't crack. Your thinking is wrong when it comes to ceilings and you are over designing.

I guess my whole point is your arch is not an efficient use of wood, and structures are not built with arches anymore because we have found more efficient ways to create clear spans that have less issues. But, if you want to do it for looks, you should, just make sure you get it engineered and that you support it from above or figure out some way to properly cancel out all your forces.

"I just need to know where I can get numbers for what appears to be an unusual solution."

You need an engineer to approve your plans.

Have you looked into doing trusses for the roof? There are trusses that can span 48' clear.

That can be manhandled by a single person working alone in the boonies with no crane and twisty roads that can't take a truck longer than 30 feet ?

They definitely make trusses that come in two pieces are are bolted together on site.

Do a google search for "pole barn" and spend some time watching videos or reading blogs, it seems everyone who build a pole barn wants to show it off on the web. Pole barns are all about open clear spans, they get that with trusses. While there definitely are guys who do it solo, I wouldn't recommend it, but I can't imagine framing any roof by myself.

Deflection limit for joists that just hold drywall is l/240.

Wouldn't L240 mean more than an inch of sag in the center of a 23' span ?

Really the only limit is how much the drywall can flex without cracking.

LOL. I hadn't even thought about drywall cracking. My issue is that I am OCD about surfaces that should be flat showing wavy or sagging and my eye can pick out very small differences so they bother me. A lot.

You also need to realize that while they are in bending, if they are acting as rafter ties they will be in tension as well, which will also limit the deflection. Lastly, a majority of the time they will only have around 8 psf a majority of the time. And again, with the live load, you just need to make sure your drywall doesn’t crack.

Also if you are worried about it, a site built truss is probably a better option than an arch.

I'm seeing that #2 SPF 2x6 16" OC can span 16'-11" at 5 lbs/sf:

https://up.codes/s/allowable-ceiling-joist-spans

If all the ceiling is supporting is drywall 5 lbs/sf is ample.

If it was supported in the middle you could build the ceiling out of pairs of 2x6x16. I'd be thinking about having a support that hangs down from the roof to hold the middle of the joists. That support is holding up roughly 16 feet of joist, each foot of joist is holding 16 inches of drywall, so roughly 21 square feet of drywall. We're assuming no more than 5 pounds per square foot so 105 pounds. So that support could just be a piece of 2x4 nailed to the side of the rafter with 16d nails.

You're asking the roof to hold half the ceiling, so an extra 2.5 pounds per square foot. Probably not an issue but check your loadings.

So that gives you a flat ceiling.

If you want do do the barrel ceiling, as Freyr points out the problem with an arch is that it exerts sideways force. However, if the arch is supported from above -- again, hanging from the roof -- it exerts no sideways force. I would be thinking about making the arch from pieces of 1x3, 16 feet long, bent into shape. Above them would be some framing, and the 1x3 is screwed into the framing so that the weight is carried from above.

What does that framing look like? Just spit-balling, but I'm thinking 2x6's that run the length of the building, probably 24" apart, hanging from the rafters.

All of this is basically DIY trusses. It might be easier to buy a scissor truss and bend 1x3's along the bottom chord.

Argh, just reread. I thought it was 32' clear span, it's really 23'.

See, that is interesting. Before the question of why "Roman" arch ceiling joists wouldn't work, I originaly drew things up with a flat ceiling of 2x8s, cutting the span from 23' to 11.5' with a double 2x8 "beam" in the attic above and the ceiling joists suspended from it, while the beam was suspended from the heavy roof ridge beam. Then I tried to find info on attic "strongback" or "inverted" beams with suspended ceiling. I found lots of laughter from engineers with the bottom line being that the beam could not be tied to the roof structure and really just needed to be sized as any other beam that was only supported at the bearing ends. In the case of a 20lb ceiling, 23' clear span, and beam bearing ends 32' apart, that works out to a double 18" deep lvl. If the ridge beam could be supported by a triangular truss up in the attic at the 16' midpoint, even a 50lb roof load + the 20lb ceiling load would require just a double 12" deep lvl. But engineers on StackExchange laughed at suspending an inverted ceiling beam from a roof ridge. It seemed to me like you would just be turning the ridge beam and the ceiling beam into a 12' tall 32' long truss. Like it should work and even be overkill.

I actually own a building built around 1850 called a "suspension barn." So called because the hay lofts and first floor hang from the roof framing on wrought iron rods. It has a full basement that was originally built to be clear span. That's where the idea comes from.

I haven't been able to learn much about suspension barns other than they are rare. It seems to be the case that they're rare because they are subject to catastrophic failure if the suspension fails.

Kirk,

That roof is ideal for trusses, which would also eliminate the need for a large ridge beam. If you keep the two bearing walls you show, the longest truss would be the same 24 ft span as the ceiling framing you are proposing. I've stood that length trusses on several houses by myself.

I think I'd rather stand trusses by myself than frame the whole roof by myself.

Here you go: https://www.menards.com/main/building-materials/trusses-i-joists-engineered-lumber/roof-trusses/24-residential-common-truss-4-12-pitch/1871305/p-1482131998903-c-5658.htm

74 pounds each. You only lift one end at a time so that's 37 pounds at a time.

DC,

Have them set on the walls by the crane truck they come on. All you have to do is slide them along the top plates and stand them.

I did mention least-expensive, right ? The 6:12 trusses 24' wide are $99 each compared to $45 for 2x8 rafters and 2x4 rafter tie. So that's a possible solution for roof -- only $800 extra for trusses on the center section. Obviating the need for a ridge beam would actually wash that $800 difference, too.

Doesn't solve the sagging ceiling issue unless hanging the actual ceiling from this truss that sits 6' up on kneewalls is allowed ?

For that matter, can an inverted truss shape with the leggs attached to the kneewalls and the bottom chord of the roof truss have the peak holding up a beam that holds the center of the ceiling joists ? Now I'm getting silly -- just make the whole attic a spiderweb of triangulated 2x4 members and you can support anything from any direction, right ?

Generally trusses can be spaced 24" but 2x8 at that span can only be 16". It depends on your snow load. But you'd need fewer trusses which makes them more competitive.

A big advantage of trusses is they're going to be faster. You can get a roof on that center section quickly. That becomes your "office" for the rest of the project -- a place where you can work out of the weather and store tools and materials.

The bottom chord of the truss will hold drywall. Are you saying you want to drop the ceiling 6' below the bottom chord?

Also, once you figure out the framing, start another thread about how you're going to insulate this building. That's what we're really good at. We don't want you coming back in three months saying, "I framed my house but I can't figure out how to insulate it." The insulation plan has to be build into the framing.

My insulation plan dictates a lot of my framing being non-conventional -- kind of a hybrid of "Perfect wall" and "vented attic" without sprayfoam inside or foamboard outside and because I don't want/need the attic to be usable for storage or mechanicals. This will be my retirement home and stairs/ladders are to be avoided for when I'm older. Air handler for heat pump would be in a closet on the first floor and all ductwork in the crawlspace and walls rather than attic.

The idea was to build the complete first floor, including attic decked, then wrap the walls and attic floor in self adhered Grace Select vapor barrier membrane, then build the roof entirely above that fully enclosed envelope and with no openings from the interior into the attic -- even plumbing vents and bath/kitchen exhaust venting out sidewalls rather than attic and roof. Which means the ceiling joists would not be rafter ties, the roof and attic kneewalls would be framed on top like a second story but with no access from the first story. This is another reason I haven't even considered trusses, because the bottom chord could not be my ceiling joist and still leave my attic completely sealed off from the first floor with joist bays available for wiring, light fixtures, and plumbing/exhaust vents.

A second stud wall without structural sheathing would surround the building all the way down to the footing, supporting nothing but its own weight, the siding over tar paper, and the insulation, no roof loads at all. Then that outer cavity wall space would be filled with 8" of cellulose and the attic with 16" of cellulose. So an R60 attic and R30 wall with ceiling joist bays empty except at the eave ends where R30 Rockwool would make up for the thin attic cellulose layer there. Depending on the climate, the stud cavities might be left empty or also filled with cellulose to add another R12 to the walls. The living envelope would be vapor tight with ERV and dehumidifier controlling fresh air exchange, the insulation layer all exterior and vapor open.

Kirk,

The bottom chord will be where your proposed ceiling is. There is no need for any separate framing.

Find a friend to help you for a day. Standing all the trusses should only take that long.

Because a 24' wide truss would only cover the center of the building, and there is an additional 12' of building on each side of the great room, the bottom chord of the truss would be 19' above the floor. This is a single story house with 10.5' tall walls, 2x8 ceiling joists, and 6:12 pitch as in the sketch in the first post. So that center truss roof section would be roughly 19' which is much taller than I want for a ceiling height in the great room.

Kirk,

No, the bottom chord of that center truss can be anywhere you want it. It will look like a typical truss with raised heels, but the heels will be 6 ft deep.

If the total height of those trusses is too large to fit on the delivery truck they will either supply them with a hinge that gets stood on site, or as two pieces which will probably be separated by 2"x4's @ 24" oc on the flat running the other direction. Again, you don't have to figure out how to do this, that what the truss manufacturer is for. Show them the section, let them design the trusses. No dropped ceilings, no other framing on site needed.

Kirk,

Another big advantage of manufactured trusses is you don't need to understand how they work. Give the supplier your floor plans and let them do the layout and engineering. I'd ask for three alternatives:

- Keeping the load-bearing walls you show.

- Removing one and clear-spanning to the exterior on the other side (to reduce spans).

- Removing both and using girder-trusses for support.

That will give you some feedback on the cost of the trade-offs. (Not having interior strip footings and load-bearing walls vs increased truss prices).

The problem with truss bottom chords being the ceiling joists is that I wouldn't be able to isolate the attic space from the living envelope, which is one of my design goals. I want an actual attic floor with a vapor membrane and all wiring, plumbing, duct work, light fixtures within the envelope, not buried in 18" of cellulose attic insulation. I know it isn't in the sketch, but DC Contrarion asked about my plan for insulation and air tightness.

Kirk.

And you want that dedicated service space just over the main room, not the ones on each side?

One other thing to remember is that the main attic, the roof space above, and the smaller ones on each side are tall enough that most codes will require an access hatch to each one. That's worth planning for now as that's a lot of hatches to find room for on either the gable ends or ceilings.

I want the ceiling joist bays empty everywhere to host wiring, plumbing and vents, with nothing in any part of the attic.

The kneewalls would be 2x4 studwalls with 24"oc studs. Is that 22.5" gap not considered enough space to squeeze through for accessing the attic areas over the side rooms from a single hatch into the central area ?

Those kneewalls and the tension tie from each of them across the rafters bases should provide at least 5' headroom and a single exterior hatch in the gable end at the rear of the house 22"x72". Does code actually require access from the interior of the house, or just "access" with an opening minimum 22"x54" ? There would be no appliances, ductwork, or plumbing in the attic, so this is just for inspection to identify roof leaks, right ?

Kirk,

I think I'm finally understanding what you are suggesting. . I thought the attic was to be kept in the conditioned space.

Yes you are fine with one access hatch, and locating it on a gable end makes a lot of sense to me.

I see your sketch now. I think your best best would be to make them out of 2 or 3 2x12s, cutting the curves with a jigsaw (or careful work with a circular saw), connect the pieces with plywood gussets and hang the assemblies from the ridge with vertical 2x4s.

If that could be done with three 8' 2x12s and a half sheet of ply, it would cost $60 each joist. If that assembly was as strong as a plain 2x12 full length, they could theoretically be 19.2oc and cost only 3/4 as much as full length 24' 2x12s. After cutting the curves into them, would they be that strong, though ? I think the deepest cut in the center section wouldn't leave much joist depth. Cutting into more pieces would require more plywood gussets and cost but leave more joist depth. And doesn't the same outward thrust problem occur ? Seems like essentially the same as kerf cuts that leave half the joist depth and then glue rather than ply gussets. What about a pair of 2x8s where the kerf cuts are offset then glued and nailed together as sisters into curved 3x8s at 24"oc ? That way the 10" segment of one would be gusseting the other and each kerf would be fighting the tensile strength of the long fibers in the other 2x8.

I am not fixated on a curved ceiling, only wondered if it would be more economical and sag less than a flat ceiling by making essentially highly crowned joists with kerf cuts and gluing.

The consensus seems to be that the outward thrust on the sidewalls ruins my oh-so-simple and inexpensive plan to use less lumber.

If I am allowed to suspend the center of the span from a ridge beam, then a 2x8 flat ceiling would be less than half the cost of gussetted 2x12s. It would also make my attic floor decking continuous, locking the ceiling joists and decking into one strong diaphragm where the curved joists would make it discontinuous.

So it seems there are many reasons why a structural curved ceiling is not worth the effort.

The key is to making the curved assembly work is to hang it from the ridge using a vertical 2x4. That cuts the effective span in half and eliminates horizontal forces. Or, more accurately, moves them to the rafters. If cost is your main concern, then yes, using smaller, straight boards hung from the ridge is a better option.

[replying to #30]

"Depending on the climate, the stud cavities might be left empty or also filled with cellulose to add another R12 to the walls. "

"Depending on climate" makes me think you haven't chosen the house site yet but you're just planning now? That's good, there's no such thing as too much planning.

Have you read the book, "Pretty Good House"? It's all about building with quality and affordability. A lot of the things you can do to make a house better don't add much to the cost. I think you'd like it.

My overall impression looking at your plan is that generally, if you're trying to build economically, you make the shape simple and you make it longer than it is wide. So if what you want is roughly 1500 square feet on a single level, rather than making it 48 feet wide and 30 feet long, think about 30 feet wide and 48 feet long. The 23x30 great room can go widthwise, leaving 25x30 for your other rooms.

With this configuration you would have a total of 96 feet of foundation, versus 120 feet in what you're proposing. That's going to save real money. Also, as drawn your great room is only going to be able to have windows on two walls, which isn't so great.

What is most economical construction varies a lot by region, but in most of the USA if you're building a no-frills house you build a rectangle with a roof made from trusses. A 30' truss is less than 100 lbs (https://www.menards.com/main/building-materials/trusses-i-joists-engineered-lumber/roof-trusses/30-residential-common-truss-4-12-pitch/1871431/p-1482132000073-c-5658.htm for example) if you had to you could transport it in the back of a pickup truck. Although I agree with the others that you should hire a truss company, tell them what you want and let them worry about delivering them, that's what they do. I think a truss company will be able to design a system for you where you have an air barrier above a service chase and insulation above.

While it's a great goal to do it all yourself -- I love being involved in every stage of a project -- you have to be honest that's not possible. Are you going to build a kiln and make your own cement? Forge your own nails? The key is going to be figuring out what pieces you keep for yourself and what you farm out. I'd farm out the trusses, and also the roofing. I don't like working at height, and a roofing crew could knock out that roof in a a day, and from then on you're working indoors.

I'm not a big fan of slab-on-grade for residences. Especially if it snows, you want your floor off of the ground. You want your walls off the ground. Even if you want the house to be accessible and stairs-free I'd rather work in a ramp and get off the ground. Will you have a garage? One option is to have an accessible entrance through an attached garage that is at the same level as the rest of the house.

Finally, I do like your insulation plan. You might want to start another thread just about that once you figure out how the house is framed and we can help you tune it.

One other point on the insulation plan: I would use the service chase to tie together all of the plumbing vents, and then bite the bullet and put one hole in the air barrier and one in the roof and run the vent straight up. You should be able to make those holes completely sealed, and it will just work better that way.

Most of the lots I've looked at will work better with a house that is wider rather than deeper, either because they are on a slope in the mountains or only 110' deep in the desert and I'd like both 40' of depth out front and still room for a lap pool out back. Being able to look across the great room into the back yard is desirable, even if it isn't very feng shui, and having the master split away from the guest bedrooms and bath is important. I've tried dozens of floor plans, and looked at hundreds for sale, and this seems to be the best compromise of views and room sizes for 3br2ba in 1400sf. Not absolutely the least expensive build, true, but I think I am getting an open and large feel in a small square footage.Here is a floorplan to visualize.

I also dislike slab on grade, since I've experienced slab leaks and insulation and flooring choices cancel the cost savings. My plan is crawlspace foundation to 3' above grade, and outside ramped paths up to floor level. Then 2x10 floor joists, spans limited to 12'. That actually means about 210 linear feet of footing, which will be expensive, yes. I'll do the excavation and formwork for that, but hire the pour, then build block up from the footings and fill the cells myself. Framing stick built additions I've done before and enjoy, even roofs, so figure I can save money there. Same for wiring, plumbing and drywall.

The great room includes a 13x18 living room/HT and 10x18 dining area across the front, and 23x12 kitchen w/walk-in pantry across the back. The home theater section needs an 18' blank wall 10' high for screen and speakers. Which I now realize means a big curved ceiling is not going to work -- the acoustics of even shallow barrel vaults are not good for home theater. I am trying to envisage the acoustics of a "coffered curved ceiling" where the space between the joists follows the curve we've been talking about but a tension tie 2x4 across the bottom made each curved joist into a bow truss with flat bottom eliminating the side-thrust. Wrapped in drywall, at 24"oc those truss bottoms would be only 2 3/4" wide and the curved space 21" wide. Would look odd, I think. And the curved ceiling making a 2' tall hump into the attic would mean cellulose insulation in that area would need segmenting or just Rockwool there instead at triple the cost

I do plan a 2car garage, but detached and all concrete block. I figure cars are all going to be EVs in future, and battery fires are a real concern with the current gen vehicles. A detached block garage will give more time to save the house itself.

kirk - you wrote this, "Sorry if I gave the impression I was trying to avoid rafter ties. I am only talking about the ceiling of a single room, and the roof is a separate structure. The ceiling joists would not act as rafter ties, but there would be rafter ties above in the attic."

I haven't read all the replies so please excuse me if I repeat anything.

If I understand, the space above this curved ceiling would be unused attic space. The ceiling joists would be supporting nothing other than the drywall ceiling and insulation.

It seems to me the economical approach would be NOT to do this as a single, simple span. Rather, suspend the ceiling joists from the trusses above. In other words have 2x3 or 2x4 stock facenailed to the joists and facenailed to the trusses above. You could space these as closely as you wish. Space them close enough and your ceiling joists could be as small as 2x4s themselves. The only point is that you'd need to make sure your trusses can handle the small additional load.

This was how ceilings were commonly framed before WW2.

As long as suspending the joists from above is allowed by code, that could be fine. Those could not be face nailed to the joists because there would be an attic floor in the way, but maybe an upside down T with a 2x6 flat on the attic floor with another 2x6 standing up as a strongback to keep the ceiling flat, screwed "up" through the flat 2x6, then the assembled T screwed down through the attic floor and into the tops of each joist with two 8" Timberlok structural screws. Then that assembly could be hung from the trusses or rafters as you suggest, cutting the span into 1/2 or even 1/3rd making a very stiff, flat ceiling with 2x8s at 24"oc. The hangers would not even need to be every joist, but every 4' maybe with the strongback keeping them all straight ? If cutting the span into 8' thirds, those hangers would be 10' above if connected to the rafters, though. It might be simpler to just brace 12:12 every 12' to support the ridge beam making the ceiling joist there the bottom tension tie, then hang one strongback from the ridge beam at each. Having the ridge beam supported back down to the sidewalls every 12' would allow the ridge to be as small as a double 2x10, think.

Adding up the lumber and Simpson connectors and screws costs for all this, I'm not sure it ends up being more economical than a simple 2x10 full span ceiling. I still think it would be stiffer than 2x10 spanning 23', though. And a strongback with suspension from ridge or rafters could be added later if it sags more than I like.

Kirk,

"I'm not sure it ends up being more economical than a simple 2x10 full span ceiling... a strongback with suspension from ridge or rafters could be added later if it sags more than I like."

That sounds like a good strategy to me. You will know well before drywall whether you like the feel of that ceiling.

Have you got a source of lumber that long? Here you would be looking at getting it milled as a custom order.

Supposedly available here in SoCal. https://www.homedepot.com/p/2-in-x-10-in-x-24-ft-Number-2-and-Better-Green-Douglas-Fir-Dimensional-Lumber-2264-24/318033446

24' for the great room ceiling and 12' for the side rooms will only get me 6" overlap on the ceiling joists where I'd like 12", but 6" meets code and there is a big jump in price from 24 to 26 or 12 to 14. With 23/32 OSB on the attic floor, should be plenty tied together, just have to remember the overlap should fall in the middle of each sheet.

Not KD 2x10s, which means full height blocking and bridging as well as an attic strongback to get an even semi-flat ceiling. At least KDHT for studs is easy to get so if I pick and choose I should be able to find enough straight ones to build straight and flat walls for kitchen, bath, and the HT screen. HD lumber quality is sometimes not great.

I still think you'd be ahead to build with trusses that are shaped exactly the way you want. Even if you don't want to go with factory-made trusses, you could build them on site.

OK, how about this:

Stand the interior walls at the height of the ceilings. Above the walls, put floor trusses (like https://www.menards.com/main/building-materials/trusses-i-joists-engineered-lumber/floor-trusses/16-x-28-trimmable-end-floor-truss/1883983/p-1444448823937-c-5659.htm ). Then plywood over the trusses, seal the seam and put on your vapor barrier. Then roof trusses over the floor trusses.

As soon as the floor trusses are covered you have a roof over your head, basically. The trusses give you a very open space to run mechanicals, and absolute air and moisture sealing.

The floor truss I linked to is much stronger than you need, you could probably do something less beefy.

Sorry, I mispoke when I said I wanted the joist bay open. I don't need them to be laterally open, just longitudinally open, not filled with ductwork or insulation, so sawn lumber is fine. Those trusses seem like overkill, although I didn't see their load rating. My 24' wide current garage uses that design to support bedrooms and baths above, but 14" tall and double 2x4 upper and lower chords. Selecting your link for 12' truss for the siderooms and 24' over the great room comes out to $4500 without even looking up the cost of the 16" rimboard. 2x8 at 12"oc for the great room and 24"oc over siderooms is $1200 for L240, so quite a difference. 2x10 at 16"oc everywhere would be $1400 giving L530 deflection at 10lbs live and 10lbs dead. Even though the AWC calculator defaults to 20/10 ceilings, you have all convinced me 10/10 and L480+ will be fine. And if it isn't, the attic suspended strongback can be added.

Decking and Grace membrane to get out of the weather was always the plan no matter which joists I decided. Only worry is jobsite theft of all that juicy 2x10 stock between delivery and install. I would think trusses would be less tempting, targets but maybe not even then.

Regis, I think 2x10 at 16"oc is my final answer.

Kirk,

Good luck with your build. I hope it's an enjoyable experience.

Thanks for all the ideas, everyone.