Backer rod instead of canned spray foam

Hi everyone,

I’m in the middle of putting down my basement subfloor (Delta-FL, then 1″ XPS foam, then OSB).

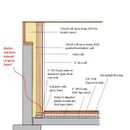

Because we’re in a rush to get it done (baby on the way), we had to do things a bit out of order and have the drywall contractors get started before we could do the subfloor. We also opted to use foam blocks with drainage channels under the framing (http://www.floodsill.com/how-floodsill-works.aspx) and closed cell spray foam for the walls so the subfloor is all going to be installed inboard of the framing (see attached detail drawing).

I think the usual recommendation is to air seal the edges of the foam layer with canned spray foam but because the drywall comes down close to the surface of the foam, I think it will be difficult to get the tip of the gun between the framing and the XPS sheets and generally avoid making a mess.

I’m wondering if I can instead get a good air seal by stuffing oversized backer rod into the gap between the foam and framing. Some pictures of the drywall-XPS joint are attached. Note that the Delta-FL has already been air sealed to the framing using vapour barrier tape.

Thanks in advance for any advice.

-Patrick

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Backer rod generally works better as it is more flexible than sprayfoam. It will have some give as the floors expand/contract.

Sometimes it is a PIA to get the backer rod in and if you don't have the exact size it doesn't work. Spray foam is much more forgiving on this front. What you can do is put a drinking straw on the nozzle of the canned foam, a standard straw slides nice and snug right over it. The straw is much easier to shape and squeeze into tight place.

Thanks for the quick reply Akos. I ended up going with spray foam. I was able to get these little tips that attach to the end of the spray foam gun and give a smaller nozzle. That allowed me to fill the gap between framing and the foam up to the level of the drywall. I realized also that I can have the OSB sheets sit plumb with the drywall without issue...the baseboard trim will hide the joint.

As a general statement, I suggest that once it hardens, spray foam in gaps is the least forgiving air sealing method when it comes to movement. A compressed gasket should still seal with 50% movement 50 years from now. Good tape should have no problem with a gap that cycles from 0" to 1/4".

Blower door directed air sealing is always important - but it says little about the future.

I’ve also wondered about the long-term durability of canned spray foam as an air seal. I’ve thought about using the “door and window” type that stays flexible with the thinking that can move around a bit and would be more likely to stay attached. On thick gaps, maybe a bead of the “door and window” stuff to act like a gasket and fill the rest with the usual hard stuff?

I haven’t done any tests, this is just something I’ve thought about a bit.

Bill

So I ended up going with door & window foam. Bill, I agree with your assessment of it. It seems much more flexible than other types of spray foam - in fact once cured, it is almost as compressible as backer rod. In the end, the door and window stuff actually ended up functioning just like backer rod because I had sealed the edges of the Delta-FL to the foam blocks under the stud walls using contractor's sheathing tape (the blue Tuck Tape) and the foam spray foam wouldn't bond to it. So it ended up essentially being a custom sized backer rod, which seems like a perfect solution.

Thanks for all the comments everyone.

-Patrick

4 years ago I deconstructed several walls in the master wing of my house. In the process of removing drywall from several walls, I noticed that every single wire and plumbing penetration that had been sealed with gun foam was no longer sealed as the foam had totally disintegrated and turned more or less to dust. Home is in central Indiana and was built in 2001. So in a 15 year span, the gun foam was totally gone. Such is the fallacy of a single point in time blower door test. I'm sure at the time of the test the numbers were acceptable. But 15 years later, not so much. Same can be said for contractors using latex caulks for air sealing in new construction these days. The result of their work might pass the required BD test per code requirements at the time of construction, and since that is all they are required to meet, why would they worry about using more durable/flexible materials?

There are also issues with application and something is better than nothing. My own home had wire penetrations sealed with what appears to be globs of liquid nails glue. The hard plugs had separated from the wood, but were still in place like a loose fitting cork in a bottle.

It seems odd to me that spray foam would disintegrate unless exposed to UV. Outdoors, I use duct seal, which is a tar/clay like material. It holds up well, and critters won’t chew it, but it eventually hardens and needs replacing every 10-15 years or so.

Bill

Agreed - various bad ideas will work OK for the blower door test. If not gaskets or tape, I'd use a good polyurethane sealant/caulk with all of the appropriate ASTM ratings. But how does one air seal for 100 years? How long does foam insulation last? I see some references to 75 years.

For air sealing around windows, I came across this little article:

https://snapgoods.com/insulation-between-windows-the-right-way-and-the-wrong-way/

that indicates that stuffing fiberglass insulation into the gap around the window is a good way to air seal (better than spray foam).

I was balking at the expense of purchasing miles of backer rod and caulk. I have leftover rockwool insulation, and don't mind the tedium of carefully stuffing the voids. Is this something that others would recommend as a good way to insulate that 1/4-1/2 inch gap around my windows?

Thanks

Paula

Oh dear, that blog is terrible information! It's an affiliate link skimming web site, designed to attract traffic with low effort put into building the site, and get some "free" cash flow. Take a look at the "about" page.

"Hi, my name is Adam and I blog every day

Meh synth Schlitz, tempor duis single-origin coffee ea next level ethnic fingerstache fan Meh synth Schlitz, tempor duis single-origin coffee ea next level ethnic fingerstache fanny pack nostrud. Photo booth...."

Just garbage filler text. Just as fiberglass is a garbage gap-filler.

An option is to air seal with high quality air sealing tape, and insulate with fiberglass.

Paula,

To further complicate things, in a recent BS & Beer episode Christy Cronin suggested Building Science Corp now thinks that the insulation around windows and doors should be kept back from the exterior face of the opening - or even omitted altogether. The idea being it would equalize pressure, and help stop bulk water intrusion. Air-sealing at the interior is still a must.

Nope, no one here will recommend that method because it doesn't work. What you will be installing in an air filter, not an air seal. :) If you've ever seen old black fiberglass pulled out from around a window replacement, that's because of all the air that has flowed through it over the years, bringing dirt with it. The air bypasses the fiberglass no problem. Blower door tests confirm this, as well as a stiff wind. Use window and door spray foam or backer rod & caulk/tape

Fiberglass is a good insulation material (contrary to what that article says), but it's not an air seal in any way. Canned foam does a good job if you use the somewhat soft "door and window" variant. Backer rod and caulk works too, but it's more work. Stuffing any kind of fiber insulation into the gap doesn't do anything to create a proper air seal.

Bill

Thanks for clarifying. I see that Hammer & Hand call for the backer rod & caulk combination. I did locate a more affordable source for backer rod, which would have been very expensive at the rates visible in my local building supply store. I used leftover cedar siding to create a sloped sill, so after confirming the width of my gaps I will order backer rod and proceed that way.

Maybe I will just skip the insulation there and go with the backer rod/caulk? not sure how I could "keep the insulation back from the exterior" of the window without just having a very small amount of insulation in that gap.

One related question. The person who helped me install the windows said that the shims supporting the bottom of the window aren't necessary after the window flanges are secured to the framing. I guess I hesitate to have the vinyl flanges support the weight of the windows for all time. Do people like to have those shims stay in place?

Thank you again

Paula

@Zephyr7

Interesting question. A couple of years ago while deconstructing a bathroom, upon removal of the drywall I noticed "dust" particles laying in the stud cavities atop the bottom plate. Closer inspection revealed that the single component spray foam used at the time of the build to seal the cracks in the exterior sheathing and wire holes through the top plates and wall tees had completely disintegrated. House was build in 2001. This project was done in 2012. So in 11 years, it had become completely dysfunctional as an air sealant. No direct UV exposure at all.

I've heard stories like this, but I've never seen it myself. I know UV exposure will destroy the foam, and I've seen that happen -- it tends to get "chalky", then crumbly, then falls apart. I have canned foam in some places that is 20 years old and is completely fine though.

I think it might be insect damage that causes the "disintegrating canned foam" problem, but I can't be sure. Thermal expansion/contraction can sometimes cause canned foam to seperate from things, but that usually results in a clean break and not "foam powder".

If you have reason to suspect insect damage (and keep in mind that's my best guess as to what would cause the foam to "fall apart" if it's not exposed to sunlight), you could put some canned foam, then a layer of fiberglass window screen, then another layer of canned foam. The screen would hopefully protect the "other side" of the canned foam from damage, so you'd have an insect barrier. Insect screen mesh is too small for the foam to migrate through on its own, so you can't just stuff screen in and then foam the way you can if you used something like 1/4" mesh hardware cloth. Hardware cloth is too large to help with insects though.

Bill