Sizing a Ducted Air-Source Heat Pump System

ASHP sizing/specs – whole-home HVAC design

I want to ensure we are going the right direction with HVAC for our new build (currently mid-construction). We had engineers do the HVAC design but the architect coordinated this and I want to make sure we will be happy with it before we spend so much $ on it! The bids seem astronomical (based on 0 prior experience).

Mainly want to confirm the # of outdoor units, currently just 1 (5 ton) and # of air handlers. It is all ducted.

Our total peak heating load is ~ 40k Btu/h and cooling ~ 14k Btu/h. Located in climate zone 6… winter design temp -21ºC (-6ºF) Brrrr. We will have an R80 attic, R38 walls, R20 walkout basement ICF walls, R24 slab. Lots of windows but they are triple glazed, R5.

– Aiming for ACH50 of 0.6 but who really knows where we will end up.

– L0 walkout basement ~ 10k Btu/h heating (1,176 SF w/ minimal glazing)

– L1 main level ~ 13k Btu/h heating (1,144 SF w/ lots of glazing)

– L2 upstairs ~ 16k Btu/h heating (1,069 SF w/ lots of glazing)

– total interior floor plan = 3,389 SF

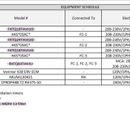

I’ve attached the specs and design below. Some details have changed but this gives a good general idea…

– Red is ASHP supply

– Green is ASHP return

– Blue is ERV supply

– Orange is ERV exhaust

– Grey is make up air

– Grey dropped ceiling

Someone kindly provided this info on the outdoor unit in my other post: https://ashp.neep.org/#!/product/51530/7/25000/95/7500/0///0 as you will see, it seems to have poor performance in cold temps! I assume this is why the backup electric heat is specified, not sure if that is required anyway or if it is simply because the ASHP can’t satisfy the peak heating loads on its own.

This unit was also shared, and it does seem much better in cold temps (+10k Btu) but I am actually not even sure how many ‘tons’ this one is, or if it can work with zones since it says single zone! https://ashp.neep.org/#!/product/78773/7/25000/95/7500/0///0

I have a 4 degree personal operating temp – 72ºF to 76ºF – anything less/more is not going to work 🤭 Precise temp control would be nice in the primary bedroom/bathroom but I don’t know how complicated that would be. I like to crank the heat in the bathroom when I shower in the winter and it seems odd to do that for the entire house or even the upstairs (currently have a unit for just bedroom/bathroom and it is heavenly).

Maybe I should just leave it to the engineer, but I’m curious to hear feedback before I call him this week.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The Daikin specced is not appropriate for your climate. It's only rated for 31K btu/hr at 5F, you need a cold-weather heat pump that will put out close to its rated capacity at your design temperature.

FYI a ton =12,000 btus. It’s just a historical term that stuck.

A ton of cooling is the rate of cooling provided by one ton of ice every 24 hours.

For quite a long time before mechanical cooling was invented perishable goods were shipped great distances by rail car, using ice. They figure out how many tons per day a car required and would load it up before the voyage. This was well-established when mechanical cooling came along and the unit was transferred over.

Interesting, so technically in terms of heating this ‘5 ton’ unit is actually 2.5 in cold temps (or less!) since it’s not at 100% capacity

I will ask about other options then that are better in the cold.

It’s fine to lose capacity in the cold as long as there’s a plan. That could be electric resistance or some sort of fossil fuel backup. Often, a fossil backup is used to avoid an electric service upgrade. That said, I have a cold climate heat pump, so I like that option.

Ahh, we do have backup electric resistance in current spec, I think my photos are blurry so you can’t read that.

I know we can’t upgrade electric service because we just installed the hydro! It’s like 800ft buried cable… but we did 2 lines - 200amp for the house and 200amp for the garage/other. We are avoiding fossil fuels so cold climate ashp seems ideal.

Given you cold climate you will want to get a ACHP with vapor injection technology. Every brand has a trademarked name for the same technology IE “hyper Heat” Daikin calls it Auroea.

https://www.daikinac.com/content/assets/DOC/Product%20Brochures/CB-VRVAURORA.pdf

You will get better temperature control between the different levels if the main floor and the second floor are separate systems. This also give you some redundancy so when something fails you still have some heat.

I like the idea of installing back up heat strips and under sizing the HP. The strip heat only runs during the few coldest hours of the year and gives the HP more run time at full speed. Sooner or later every system goes down for some reason and WHEN it happens back up heat changes a crisis into a minor inconvenience and expense.

Walta

When you say separate systems, you mean separate outdoor units not just air handlers right?

Since we originally wanted wood heat, having some redundancy would be ideal. We will get a generator and some backup batteries, but having one outdoor unit is a bit concerning since we are building in a super rural area.

Yes 2 total independent system with no common components. The only thing in common is that they draw power from the same electrical panel.

One ton = the amount of heat required to melt one ton of ice at sea level. 12,000 btu.

Separate systems will give you no different control than if they're on the same system. Even if on the same outdoor unit you have two zones two thermostats that are independent. Two separate systems will, however, allow you to heat on one floor while cooling on the other...not that you would ever need to do that. It would give you redundancy. You need hyper heating technology no question, any engineer that would design anything different in this application lacks the expertise to supply you a sound design.

“Separate systems will give you no different control than if they're on the same system.”

With separate system you get the ability to shut one system down completely. The multi split system almost always need to dump some excess capacity into some of the other heads when only one of the small heads is calling for heat because 100% of that heads capacity is less than the compressors minimum output. Making off is more a figment of one’s imagination than a reality.

A multi split compressor can not reduce its output to less than 33% of its maximum while the mini split will operate down to 10%. So lets say one needed 4 ton of equipment the 48000 BTU multi split would have to start cycling on and off when the load falls below 15840 BTUs. With twin 2 ton units you could turn off one 24000 BTU unit and have the other run at its min speed and not cycle until 2400 BTUs. The multi split is 660% larger at min speed.

Walta

Lets start with some sanity checks.

A walkout is about equivalent to a 1/2 story, so lets take it as 650sqf equivalent, add that to the main and 2nd and looking at around 2800sqft.

BTU/sqft is a terrible metric, but good for sanity checking. So you are looking at around 40000/2800=14BTU/sqft. Not terrible, but not great.

I would be expecting closer to 10 based on build specs and climate but a lot of windows can add up quickly. How many sqft of glass is there in the whole place?

The original equipment spec is 15kW of backup heat which is 51000BTU. I know these come in standard size increments, but no point in installing more than your heat load, just adds to your electrical service demand numbers.

My approach to backup heat would be is to skip it all together or if you do add it in, it should only be enough to keep the place from freezing plus add a bit in case of those polar vortex days. There is no point for it to carry the whole place at design condition as it should never need to run. That would be around 60% to 70% of design load so around 8kW total.

There is a lot of equipment with rating at -6F, the choice really comes down to what your local installers are familiar with. Most cold climate offerings from the major players (Mitsu, Fujitsu, Daikin, Carrier/Midea, LG) are comparable, some might have a bit of an edge in colder weather.

40000BTU does put you around a 3.5 to 4 ton hyper heat, many options there. IE:

https://ashp.neep.org/#!/product/64690/7/25000/95/7500/0///0

https://ashp.neep.org/#!/product/34536/7/25000/95/7500/0///0

https://ashp.neep.org/#!/product/56877/7/25000/95/7500/0///0

These are all single zone units, you can definitely install and separate air handler for the 2nd floor, just adds a bit of cost. There was some discussion in the other thread about single outdoor unit vs multi split. Either one can work but the multi split is the same overall BOM cost as two units, much harder to get right and provides no backup, I don't see a good reason to use one.

I don't know how attached you are to your window sizes but there is probably a fair bit of energy that can be saved there. Lot of windows also add a significant amount of cost. Too many windows look good in pictures but not always the best in real life as it limits wall space and furniture location.

The x30 ERV is an autobalance unit so you can save some ducting costs plus get a bit better filtering and comfort by sharing the supply ducts with the air handler. These modulating heat pumps run the air handler fan at some speed 24/7 already which will ensure fresh air deliver to the whole house. Plus this way the fresh air will be tampered so you are not dumping 12C to 16C air into the bedrooms when it is -20C outside. The dedicated ERV stale air ducting to the bathrooms should stay. I would add a stale air pickup to the laundry room as well. The main floor powder room might be best served with a standard exhaust fan. Bathrooms don't need an ERV supply whichever route you go.

For bathroom comfort what you want is resistance floor heat matt connected to a timer in addition to the feed from the heat pump. This lets the heat pump provide the bulk of the heat for the space most of the time but you can increate the temperature a bit when you are likely to use it for a bit of extra comfort. Same for the kitchen and entrance mudroom tile.

Deleted

Typical condo would have the HRV in a simplified ducted setup where it connects to the air handler only. In those cases the air handler and HRV are interlocked so the air handler fan turns on when the HRV is on. It sounds like something is miswired or misconfigured with your setup.

A properly setup ERV and well sized modulating heat pump should always run 24/7. ERV efficiency decreases as flow rate goes up, so you want the ERV to run all the time at the required minimum airflow to provide the fresh air you need. I know it is common to have the ERV/HRV on cycle timers but this is really only needed for older single stage heating equipment.

The heat pump blower will already be running 24/7 so there is not even a need to interlock. For the rare cases when the blower is off (say shoulder season with cooling and heat off) the fresh air can be delivered to the house through the return air grills.

The reason you want an autobalance unit is when you connect it like this it will see pressure changes as the air handler ramps up/down. A regular ERV would get unbalanced which will kill its overall efficiency.

Sometime it is built into the ERV, but in case yours doesn't have it, you do need a motorized damper on the fresh air connection between the ERV and air handler. This should be driven by the ERV so it will close whenever the ERV is turned off to avoid drawing air through the unit and freezing the core.

Interesting… I don’t fully understand what you mean about the rare cases when the blower is off. So, the ASHP is off and that blower is not running which means the ERV can’t run then because it is somehow connected? So the ERV fresh air supply comes out of the returns? That seems awkward, mainly because the returns are located away from where we would want the fresh air to come in. Also it seems like there would often be times we don’t need heating/cooling but simply want the ERV ventilation.

The one in our condo is definitely screwed up!

Assuming we are talking about semi ducted operation with only the ERV fresh air supply connected to the air handler.

There are two options for cases when ASHP is off. Keep in mind this is rare occurrence, normally happens in the shoulder season when windows are open.

You can do nothing, the fresh air will be delivered to the house through the return registers. Not ideal for mixing and closed bedrooms won't get any air changes. Not an issue if windows are open, so depends on how you run the house.

The ASHP fan can be interlocked with the ERV. Most air handlers have an dry contact input for this purpose. This way whenever the ERV is running, the air handler fan will be on even if the thermostat is off. This option would get you fresh air through the house even with the ASHP off.

In terms of actual layout, this is for a different brand but their diagram is better. Take a look at P4 here:

https://reversomatic.com/wp-content/uploads/2016/11/Mini-Brochure..-New.pdf

The connection would be as per the diagram labeled "HRV with Fan Coil

System". The drawing also shows where the motorized damper is needed in case it is not built into the ERV.

As for using the ERV for bathrooms, it is not an issue, I have it on mine north end of Zone 5 and works just fine. No frost on ERV, ducts or anything. Since the ERV is connected to multiple bathrooms, even if one is drawing in near 100% RH air, the rest are picking up regular house air. Once you mix all those streams together, the air entering the ERV has a bit higher water content than the house but not enough to matter.

I find that I never need to use the ERV boost switch for the bathrooms, running at base rate is enough to clear a shower, mostly use it when cooking. I would install a boost switch in the kitchen area.

There are differences to consider

Attached are examples of single vs multi in your required output range. Outputs are at -5 deg F db. Design temp here is around 0 deg F, you're farther North. Notice first floor system is larger output as in most cases the first floor heating also carries a good part of the second floor load (via stairwell). My second floor airhandler hasn't been on once for heat this winter . Not required in my situation until sustained temps below 20 deg F which we have not had yet.

Both are good options. As Akos stated, material cost is very close, slightly higher on two separate systems but not enough to matter...a few hundred bucks. Labor can go either way depends on specifics.

These single zones have thermal cutout feature at -19 deg F, back on at -14 deg F. Multi does not have thermal cutoff. That's a difference to consider if there's no backup.

In this case, COP on the single zone systems is slightly lower than the multi. COP at 5 deg F on the 2.5 ton is 1.75. Cop on the 1.5 ton is 1.66.

COP at 5 deg F on the multi is 2.0 so a little better running efficiency...but you lose turn-down.

Single zones have lower minimums, when you stack the two single systems' minimum outputs its almost the same minimum as the multi, however, the single zones can run one at a time so you can leverage their respective mins. Keep in mind the multi can DELIVER MUCH LESS (it can deliver around 7,000 which is great for dehumidification) than it's minimum output. This is often unknown/misunderstood...but delivering less than you're making is not efficient and is why multi's have poor performance in very low load buildings. When sized correctly in whole-house situations they perform very well, but yes, typically not as efficient as separate single zone systems.

The multi is actually still built in Japan, but all Mitsubishi extremely reliable.

There are way too many unknowns with actual multi split operation to really know how the system will run.

Generally a right sized multi with two large zones does work. I have yet to see a case when it works better than a one-to-one pairing though. The real world COP numbers of multi splits are all over the place, I would not trust a data sheet number.

"Keep in mind the multi can DELIVER MUCH LESS (it can deliver around 7,000 which is great for dehumidification) than it's minimum output. "

I have not found this to be the case, this is at least not the case for the non-branch box units form Mutsi and LG. If you have some test data from a system would be good to show. Also min output on most multi splits go up as you add indoor units, so it might start out at 7k, but with two zones, the actual min might be 9k. I also don't think the min can be split between units, so something with a 9k min, will not be able to run each zone at 4.5k (or at least it doesn't seem to happen in the real world as calls at such low power rarely overlap).

The one benefit of two separate systems is dehumidification in the shoulder season.

You can run the 2nd floor unit in dry mode and the main floor in heat to make up for the missing sensible load to avoid overcooling the house. Since the loads are very low and outside is mild, the COPs are very high, running like this doesn't use much energy. I would guess it would be less cost than a dedicated dehumidifier. Definitely works great for drying the place during construction after the dusty parts are done.

I like the sound of the dehumidification strategy!

The question is really what to do about the basement. I think the engineer might like my suggestion of a small 1:1 unit for upstairs, and a bigger unit for the main floor/basement. However, I don’t know if it makes more sense to have a separate air handler in the basement with ducts (as designed) or if it should be some kind of ductless setup - like a wall unit in the guest room and one in the main rec room/media area. But there is a bathroom getting roughed in down there too so at that point I don’t know how we’d heat it, maybe just electric floor would be enough.

Mitsu makes (actually Honeywell makes it) a touch screen wall stat MHK2 that works very well, and is used to program the airhandler settings also. You can add a KUMO interface and control system from smart device. I do have engineering data on how the system modulates differently when using 3rd party controller...but Mitsu does have interface so you can use them (NEST, etc). I've never had a reason to I prefer the factory controllers, but know of c0mpanies that have and had positive feedback from customer, they still do modulate with 3rd party stat just not in exactly the same manner.

Help me understand what you are trying to tell me.

Are you saying Mitsu has an open standard serial data port that allows aftermarket thermostats to share data with Mitsu equipment or are you talking about some kind of an interface that allow one to connect an old fashion thermostat W1, W2, Y1 and Y2 to Mitsu equipment and have it sort of modulate?

If the data is publicly available, please post a link.

It seems like we have seen several posts about Mitsu equipment with Kumo stats that fail to modulate in the way the owners were expecting

Walta

No way should a stale air and exhaust be that close. No need for fresh air outlet there, just stale air out is fine. ERV can share ducting with ashp, there are many different configurations some of which require air handler to run, and some where ERV can run independently. Mitsubishi air handler has option to run fan very low speed or turn off when it's satisfied. The only ERV system I know of that uses tubes is the Zehnder, great system but costly. We've used Renewaire for years with great results, so I'm not up on the latest. I can tell you the outside of ERV housing will actually frost during extreme cold, for this reason I do not use them for bathroom exhaust in our climate. The Zehnder has an internal heater to prevent freezing issues which is nice, but I prefer dedicated exhaust for bathrooms where you can quickly and effectively get rid of bulk moisture.

Even with a 78F delta-T, the 40K BTU/h heat load seems high given your build details. Can't really read anything in the attachments (given GBA's silly resolution restrictions), but I think some further due diligence is warranted.

Walta,

I'm speaking in literal terms. "Control" means to adjust, turn up or down, or turn off. Yes of course you can absolutely turn off the zone in a multi. A four ton multi does not need to cycle below your 15,000+ btu number. Sorry. I've done field testing on systems we've installed. It's way less than that, not to mention they don't pull a lot of current when cycling anyway. I've run a single 9k head on a 3.5 ton multi and measured its output at half the max and the outdoor never cycled off. Consult the older Mitsubishi technical sheets (if you can find them) you'll see what I mean. Also, the 3, 3.5, and 4 ton Mitsubishi all share the same exact minimum. It's not based on percentage output, the minimum is there to ensure oil delivery back to the compressor. However, your statement about the need to dump the excess heating or cooling is absolutely spot on and yes sir, it does result in inefficiency during low load conditions. Again, multi is not a great fit for all applications, but there are plenty where it is. Just giving the OP all information to consider

Mitsuman

Have a look the two NEEP Mitsu pages I picked they look to be similar models with different capacities of 3 and 5 tons.

https://ashp.neep.org/#!/product/33454/7/25000/95/7500/0///0

https://ashp.neep.org/#!/product/33452/7/25000/95/7500/0///0

The 36000 BTU will throttle down to 12498 BTUs at 47° or 34%

The 60000 ton will throttle down to 18330 BTUs at 47° or 30%

I did not look for the min speed of a 4 ton but it sure looks like a 4 ton would be cycling at close to15000 BTUs

When only one 6000 BTU head is calling for heat, the system is going to come on and make the minimum 15000 BTUs and the system will dump the extra 9000 BTUs onto one or more of the other heads regardless of how the controls are set on the heads. You can vote with your “control” but the system reserves the right to overrule your vote and dump load wherever the system wants.

Walta

Re: main floor carrying higher load than upstairs - do you mean that in my case even though the heat load upstairs is a bit higher than downstairs according to the original calcs, it would be a bigger unit downstairs because the heat will naturally rise through the stairwell?

Re: Mitsu controller options - I was told that it doesn’t work very well with third party devices like Nest, but if we could use a Nest I’d consider that!

Re: outside of ERV housing frosting during extreme cold - what? Interesting because I never liked the idea of ERV being the bathroom exhaust, seems weird to boost the entire house to get rid of steam in one room. However bathroom exhaust seems very frowned upon in terms of the air tightness police, almost as taboo as the kitchen exhaust I insisted on 😂

I’ll ask the engineer if they ever revised the heat loads based on the updated design before finalizing the hvac design. Seems pointless to design it based on the wrong plans but I’m not sure how much we’d have to pay to revise. Will see!

I’m wondering if maybe a multi unit for the main floor and basement could work plus a small single zone for upstairs. I’ll ask about combining the ERV with the air handlers, not exactly sure how it works since the ERV is a whole home system but might as well check!

Correct! Load software doesn't account for this. Yes, when calculating the heating load on the second floor it is specified to be over conditioned space. There is no floor load associated with the second floor since it's conditioned below, but the software cannot account for the natural convection that occurs from the warm first floor to the second floor. My second floor air handler STILL has not been turned on this winter. It was 18 deg F two nights ago, it was off. The heat from the Living room ductless unit provides a lot of heat for the upstairs. Many old houses have minimal or no ductwork upstairs because there was no AC, and the stairs were the heat duct. Cold are return at the bottom of the stairs.

The MHK2 is an easy to use touch screen thermostat. Yes you can use NEST. I was against this as I was told it has negative impact on system modulation. We raised this question years ago and we were provided with the details. I do not remember them and not sure I can dig them out but I could probably get them again. All I recall is that after seeing how it functioned I was not concerned. Believe me, I take performance seriously, and if I felt it would impact my customers negatively in any way I would have had an issue. Now, I have not integrated one with NEST personally because I don't have the desire or need. If a customer really wanted to we certainly would, and I would brush back up on the modulation aspect of it. I've heated my house with heat pumps for so many years, there was no such thing as a NEST back them and I've had no need to add it. I'm happy with the factory controllers, but I should try to take the time to be more familiar with NEST. I could install one here at my house or the shop (we heat all of our buildings with ashp) and see how well it performed. If you really wanted that controller, I would have no hesitation installing it. I would caution you about using NEST (or any other controller) for setbacks...although I've seen some new and interesting field studies that show conservative setbacks under the proper conditions can yield savings. I don't think we're there yet but I'm sure in time the controls will get there.

ERV housing frosting? YES! Years ago we installed in a new build, 6,000+ sf house. ICF crawl, stick built with closed cell spf plus a 1" XPS board thermal break on the sheathing. Roof decks foamed also. We installed the heat pump system. We recommended ERV, the house was tight and there was no code here for ventilation (still isn't in many areas but it's getting better). Large, but tight, and during construction there is a massive amount of moisture from joint compound (we call it mud), paint, concrete, etc. The air was so wet and stagnant that the screw heads were rusting and leaving rust stains dripping down the attached garage doors. It needed ventilation in a serious way. We installed the ERV in first floor mechanical room, ducted it to the attic. They built catwalks in the attic for us and we installed a duct system for the ERV up there. It was winter. We finished the install and balanced the ERV. It was really cold out, probably zero deg F or below. I went back the next morning to meet with customer and discuss use. Outside air still extremely cold. I checked on the unit. Moisture in the air of the conditioned space was frosting on the housing of the unit. I scraped the ice off the unit with my fingernails...like back in the day on the school bus with single pane windows. Look, it's a metal box with some foam board insulation, some fans and a core. That cold air makes the unit cold. If there's no heater inside like the Zehnder unit, moisture can freeze during extreme temps. Not a concern for many climates but it is here. I choose not to invite problems when I design and I think putting bulk moisture into an ERV when its really cold out could be problematic. Ice is not good for mechanical systems and I'm sure the core could freeze...I mean the outside of the unit was freezing so what's going to happen if you dump a bunch of bathroom steam into it? Zehnder doesn't use a heater in their unit for no reason.

My opinion is get moisture and smoke out of the house quickly and effectively. I have a customer that build timber frame SIPS house years ago, it was so tight the blower door didn't go low enough. They had to test it with duct leakage tester. They have a beautiful Italian built gas stove and right above a nice vent hood. They didn't at first, and then they tried living there. Roasting a turkey was a problem. I'm Italian, I love to cook. I sear meat at high temps in cast iron, I make homemade stock on the stove, etc. lots of smoke and steam. You need direct exhaust it's impractical not to have it. Most houses we ventilate have an ASHRAE 62.2 requirement of ~70-150 CFM. My upstairs bath alone has that and I have a daughter that takes really hot showers and can still steam that room up! I don't have the fan on a separate switch either, I wired with the light so if light is on, fan is on. Obviously big bathrooms, high ceilings all that helps, but using ERV for bathroom relies on ERV being on to dry out the ducts. If ERV fails now you have no exhaust, ducts stay wet, and as filters get dirty you lose ventilation. I'm not saying it can't be done and it's done frequently in hotels, etc...but in a new residential build I like the right tool for the job. Exhaust fans for exhaust, ventilation equipment for ventilation. Are you putting your house in negative pressure and bringing in outside air when the exhaust fans are on? Yeah...so? There is a balance between the extremes you'll get from the air tight police and practical design for every day use and happiness. I'm all about build it tight, ventilate right but I'm cautious with extremes views in any subject. In my experience, extreme views (building science) come from those with a lot of theoretical knowledge and much less knowledge or experience in applications. Not saying that's always the case and I've learned a LOT from others over the years, but there is absolutely no way I'm not having exhaust above my cooking area! I'm sure there are ways to efficiently integrate make-up air if needed and this would be a good place to learn about it. I'll be building an ICF house next year and I will be asking some questions about it and learning what the best approach for me is. I'm sure there is someone here that will have good info, I'm impressed with the level of knowledge on this site.

Is it optimal to have a Zehnder type ERV with dedicated tubes going throughout the house strategically removing stale air and delivering fresh? It sure is, but I've put ERV's into problematic houses and take care of the issues with one stale air intake and one fresh air supply. Both on the first floor of two story house, and have done it multiple times. When it's all you can access that's what you do, and it works. I actually have to go look at one of these exact cases Tuesday and most likely will be tying ERV into existing air handler that services only part of the main floor in a two story.

You're on a good track, but it would be multi for main floor and upstairs then single for the basement. Basement load is small, you can really leverage the turn down of the single for that system and keep the higher output/lower turn-down applied to the greater load where it belongs. Plus it's a different environment down there. If you're sweating it out in your basement gym in the winter and want ac, you can have it with a single zone. If it's part of a multi system, you're stuck with heat only down there in the winter because the other two floors are heating.

As far as the load, yes you should always have it updated/accurate as it's what the design is based on as you pointed out. Those revisions to the load take a few minutes for an experienced person, it shouldn't be a big deal.

Walta,

I'm referring to the multi zone systems we were discussing that relate to this project (hyper heating systems designed for residential, low ambient primary heat applications). The models you referenced are City Multi VRF systems. Commercial VRF equipment is not applicable to this discussion. You want to look at MXZ-C (HZ) model numbers for smaller loads and the MXZ-SM (NAMHZ) model numbers for larger loads. I was referencing the MXZ-SM36NAMHZ, 42NAMHZ, and 48NAMHZ (3, 3.5. and 4 ton) branch box systems. All use same exact compressor, same hardware, etc. The 36 makes 42,000 btu at 5 deg F (used to make 45,000 they turned it down), the 42 makes 48,000 btu at 5 deg F, and the 48 makes 54,000 btu at 5 deg F. All three have same minimum output. Again, the minimum output is not determined by percentage of output, it's determined by necessity of compressor to ensure oil delivery at all times. That's why those three have the same minimum output. They're all rated for same piping distances, height differences, etc. all of those affect oil delivery.

You are absolutely correct in your statement regarding the "heat dump". Basically they leave the expansion valves open a few steps and the excess hot gas circulates throughout the piping, and the system takes only what it needs to satisfy the load at any given time. So yes, during low load conditions efficiency takes a hit for sure. Keep in mind that Mitsubishi publishes the true minimum, as in the minimum output being created by the compressor. They used to publish the minimum "delivered" output which did not include the extra capacity that's "dumped" that you are referencing. Not all companies publish their true minimums, some still publish the "delivered" so when looking at minimums between manufacturers we have to be cautious. Mitsubishi is notoriously conservative in their ratings.

What everyone needs to understand, is customers are not all engineers. Believe me, I have WAY more customers that could care less about that efficiency loss, they simply do not want to look at more than one outdoor unit, or they simply do not have a place to put more than one. In the majority of cold climate applications, the multi performs exceptionally well. It is very efficient over the course of the heating season.

Just because you and I understand the technical side and put a heavy value on efficiency of does not mean it's the top priority for the customer. The annual savings on two singles vs one multi in a typical application is just not that substantial, and often the trade off to the customer isn't worth it. They prefer the multi. Each situation is unique and each customer is unique, so it is the customers' situation and preferences that will determine what's best. As far as the redundancy thing goes...yes, at some point a mechanical system will fail and it's inconvenient. In these new, high efficiency builds where ashp is sole source of heat, the loads are pretty low as you know. A few space heaters go a long way and are easy temp heat unit repair made. Many houses have gas fireplace for ambience that can be used also. These systems are EXTREMELY reliable when all is done as it should be. I get it, redundancy is nice and a little extra peace of mind, but any good installer should be confident in supporting the equipment they install. We have done many projects with all single zone 1:1 systems, we've also done many that were a multi split with a single zone kicker (my house is like this), and we've done many that were just multi split. In each case, the systems perform extremely well and the customer is very happy with the result. We put a lot of time and effort into determining what the best solution is for each project to ensure they're happy and their priorities are met. We cannot paint with a broad brush and tell everyone one solution is best. We have to determine what solution is best for THEM. To me, a properly installed outdoor unit with clean electrical and pretty piping with nice termination is a statue of mechanical prowess to be admired! Not everyone feels that way, most people want it out of site and of course we typically try to get them on a gable that's out of view. Also, not all companies provide installs that are nice to look at, but there is much to consider when designing.

Dismissing the value of the multi split can be a disservice to the customer. That being said, yes, again, typically the 1:1 is efficiency king, but that doesn't mean the multi split is the useless energy hog that it's sometimes framed to be. They're very efficient when applied correctly. I'm in hundreds of houses a year and can tell you that it is an exceptionally useful tool and is often necessary in designing the system that best fits customers' ideal solution.