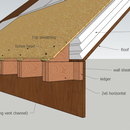

Applied Overhang Design with a Foam Overroof

I’m looking for any feedback on these applied overhang designs— see attached. There are 3 details, all very similar. Detail 3 is probably the simplest… I’m getting into the weeds on which is best in terms of constructability for a contractor that has never executed said detail. Or do you see better courses of action?

This is a retrofit project on a cape style roof- 6″ of foam applied over the sheathing, zone 6a, Maine. I want to provide a detail that streamlines the process, i.e. is simple and generates good results, keeping costs minimal for this particular detail and doesn’t scare roof contractors away.

One contractor has suggested the use of 1×4’s for strapping to create a vent channel. I like the added robustness of the vent channel (I understand it’s not strictly necessary) but I am wondering if 3/4″ is enough material to attach the top layer of sheathing to. I have seen this detail specced with 2×4’s. Any thoughts?

Note: the details do not show any membranes, etc. There will be an airtight membrane (ice and water?) over the original roof decking and underlayment on the top layer of sheathing of course.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The building code requires at least 1" for roof vent depth, and Joe Lstiburek has published research that shows 1 1/2" or more is better. I would use at least 1" rough-sawn or 5/4 surfaced furring, or preferably 2x material for more effective venting. Also, sheathing fasteners are supposed to penetrate framing by at least 1 1/4".

Thanks Michael, always nice to hear from you.

Hoping he doesn't see these details as need to increase his estimate much (original estimate didn't include overhangs since original house doesn't really have overhangs).