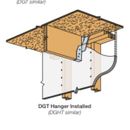

Framing with Simpson DGT and DGHT Hangars

I was browsing Simpson’s catalog and noticed a new product.

it’s a firewall rated hanger that keeps the floor joists/trusses spaced off a wall enough for double 5/8″ rock (1 1/4″).

they are expensive at $50 a piece.

however for a non fire rated wall assembly I think it would be clever to use to eliminate the rim joist on two story projects and on 1.5 story projects.

with the floor system spaced off and held within the exterior wall there wouldn’t have any rim insulation detail to worry about just standard wall cavity details.

https://ssttoolbox.widen.net/view/pdf/mygsk3p7nt/F-C-DGTHANGER23R.pdf?t.download=true&u=cjmyin

the notching around the hangers is straight forward too. .

thoughts?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You could set the rim joist on the interior, frame the studs a bit differently, and end up with a sort of let-in like rim joist, allowing insulation on the exterior. This might end up beging cheaper, or about the same cost, to using a bunch of those fancy joist hangers. The only problem I can see with those hangers is that $50 per joist is going to add up to a good amount of money pretty quickly.

If you were using thick exterior insulation already (I like 2" plus), then the need to insulate the rim joist is much less of an issue and you don't really need to do anything special on the interior.

Bill

You need one at each end so it's $100 per joist!

I was thinking maybe you get lucky and have an interior beam on the other end, which would be the best-case scenario :-D

I think in practice there would also be some extra framing charges from the framers "what is this @#%! thing? Better tack on some extra hours to deal with this" charges too.

Bill

I do wonder if they are relying on the compressive strength of the drywall to provide a horizontal reaction force to the joist to lower the moment induced on the top overhanging part of the hanger.

The reason I bring this up is because if you are installing drywall up behind the joists, depending on joist height and finished ceiling height, you are either going to end up with 54" wide drywall or an extra seam.

Even if you didn't need the prescribed fire rated assembly these provide, you'd still need some vertical to horizontal fire blocking depending on the insulation type you're using in the wall, if the drywall was not full height.

Cool product, but might introduce more problems than it solves except when used specifically for why it was created.

I think you'd also want something to screw the top edge of the drywall to.

I know Simpson makes a joist hanger that is really a hanger -- it nails onto the top of the wall, not the face. It's used with steel beams, where you put a piece of 2x on top of the beam and nail the hanger into the piece. I think you could use that hanger on a 2x4 wall if you wanted to skip the rim joist.

>"I think you'd also want something to screw the top edge of the drywall to."

This made me think of something else: This hanger will mess up the usual order of construction operations. The framers now need the drywall guys to come in an drywall the inside of the exterior wall before the framers can install these hangers and the second floor joists. That also complicates the exterior walls, since they often rely on the second floor framing to keep from falling over as the structure is going up. Those are significant downsides to trying to use these hangers, which will add costs to the project and more potential for project delays too.

Bill

> The framers now need the drywall guys to come in an drywall the inside of the exterior wall before the framers can install these hangers and the second floor joists.

Perhaps. I had assumed you gap them during joist install and drywall guys slide drywall under like they do with a "slammer" stud in steel stud framing.

Even if that's the case, someone has to make sure they do the walls first, because many crews like to hang the lid first.

I think you'd have to gap and slide. Otherwise that drywall has to be up before the roof and would get rained on.

Bill, they are designed to allow the drywall to be installed after. Which is the selling point of them.

Simplicity prevails. :-)

I called Simpson and they are tested without any drywall installed, or so I was told.

sayn3ver,

My initial reaction was much like the rest of the posters, but I'm warming to the idea a bit, although I'm not sure it buys you much.

Unlike on multi-family, you wouldn't have to notch the drywall, just run it up over the lower top-plate. Having to do the walls before the lids would make the drywallers crazy, and floor joists can vary a bit in height, so that might be a problem too.

The cost is a huge impediment. If you wanted to pursue something like this, would it make more sense to just fasten a ledger to the interior of the walls, and use regular hangers to hold the joists?

The joist bay is used a lot for mechanicals, which presumably you'd do before drywall. If you have anything going through the wall to the outside it's probably going through the joist bay -- vents, HVAC tubing, electrical service, etc.

If the drywall is going up the wall through the joist bay then the drywall guys have to work around all that stuff, plus any wiring.

DC,

Good point. A real impediment.

Along with Swedish platform framing, this feels like a solution looking for a problem. The only time skipping rim joists would make sense is with 1 1/2 story where you want to balloon frame the walls. In that case there is no top plate to hang anything off of, so the hanger won't help.

If you are looking for continuous insulation around your floor joists, most codes allow for the wall plate to be offset 1/3 the plate width. With 2x6, this allows you to inset your rim joist 1.5" and install rigid there. Near standard construction, you can use pre-cut studs and no joist hangers to buy/install.

Having a rim joist also means you can push your window headers into the rim joist.

I've never seen the inset band/rim joist detail before. I had to go look it up.

Certainly cheaper and gets you external insulation.

How does the inset rim board work out with the trades? On deeper walls no big deal I'd imagine.

You get 2-1/2" in front of the rim on a 2x6. Perfect for electricians. I kind of like the idea that it makes it hard for the plumber to run pipes there because I wouldn't want him doing it anyway.

Thanks for that.

Out of curiosity, is this allowed when floor trusses or i joists call out for a structural rimboard (1.5" rim vs 7/8", 1", 1.25")?

I'm assuming with a double 2x4 wall with the exterior facing studs as the load bearing framing you get no real inset.

sayn3ver,

The cantilever of the bottom plate is independent of what floor system is used. As Akos said, under Canadian codes it's 1/3rd of the plate width. You should confirm what your's says, as when it has come up here in the past 2" was suggested as the maximum for a 2"x6" wall.

If you go that route, make sure to think out where your sheathing joints fall to tie the two stories together.

I don't think this will fly with a 2x4 wall, 2x6 min.

This is specifically in our code, so it is easy to do plus it is something done all the time to a small extent when the foundation is not square. I can't speak for your local code but I can't see anybody objecting to Malcom's idea that if a 2x4 wall is allowed, having a 2x6 with the same amount of bearing as 2x4 would not work.

Quick google did find this link, not code but the force distribution rule of thumb can also be used for walls:

https://sbcindustry.com/system/files/sbca/educationalprogram/node/pdf/1187/educationpptcantileveredsillplate.pdf

The only issue I would see with trades is installing the rigid. You would have to make sure the correct sized strip of rigid is at the site and watch that it is built as per drawing.

Thanks again. I haven't been able to locate it in the IRC on my mobile yet.

sayn3ver,

My mind is like a sieve these days so take this with a grain of salt.

As I recall the times this has come up on GBA, the argument for the two inch cantilever was you still had the same bearing left as when you use a 2"x4" (which I'm not sure is very convincing), and in the context of creating a step in a stem-wall to allow foam between it and the slab - where I thought the discussion said the IRC wants full bearing under framed walls.

Like you I'm having trouble finding anything in your code, but I'm not that familiar with navigating it.

Advantages I see are that you don't need to pay for or install a rim joist or ledger, which would recover part of the cost of the hangers. It eliminates the risk of the rim joist shrinking, which isn't always a problem but it can be one. A big one for me is that it makes it easy to do a good job with cavity insulation; getting the rim joist areas done is always challenging, or involves foam which I try to avoid.

Mitek's FWH is better than the Simpson one I originally posted about. It is a much easier detail to cut for drywall installation. They offer a template that allows one to use a spiral cutter router (rotozip) to make the notch.

The Mitek product also has a detail that allows the hangers to be installed over 1/2" sheathing (interior sheathing) which one could then utilize interior sheathing as the air barrier and a non wood panel sheathing on the exterior like fiberglass faced gypsum which gets the sheathing inside insulation layer without continuous exterior.

https://www.mitek-us.com/products/ewp-hangers/fire-wall-hangers/fwh/

I understand it is an expense without much gain per say, but rockwool batts install nice and fast in standard cavities. And these brackets along with the simpson allow the drywall to be installed after the building is dried in and any carpenter can install joists hangers.