Another wall — Is this a good idea?

I recently visited a home zone 6 with this wall detail.

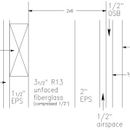

It appears to be an interesting way to achieve R27 or so between studs, but is this a good idea?

Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Greg,

It's a little weird.

The horizontal strapping on the interior makes it a Mooney Wall -- sort of. Most Mooney walls have fluffy insulation filling the interior 1.5 inch thickness of the wall, not EPS. But the EPS can work.

The odd part of this wall is taking up the 2x6 stud space with a 1/2 inch air space -- what's that about? -- and cut-and-cobble foam. I would prefer to see the 2-inch-thick EPS installed as a continuous layer on the exterior side of the OSB, rather than cut into narrow strips and inserted in between the studs.

Finally, this wall has no rainscreen gap -- unless the steel siding is corrugated. So I give it a thumbs down.

My 0.02$

Seems a little silly to me...

Why put the EPS BETWEEN the studs as this does nothing to prevent thermal bridging. More importantly, EPS foam has about the same R value per inch as the fiberglass batts. Somebody had to cut that foam and stick in there, adding extra labor costs and higher material costs. (EPS is more expensive than fiberglass batts).

Because they are leaving 0.5 inch of airspace, the over all R-value is lowered further with no discernible benefits. I'll add that the insulation dimensions add up to 6" rather than the actual 5.5". So something is off here...

I think you could take the same materials used in the assembly and rearrange them to make a far better wall in terms of R-value, and proper vapor/moisture control/building science.

Using 2x4s instead of 2x3s or 2x2s for the horizontals is a mistake- it more than doubles the minimum necessary framing fraction of that layer. You'd be far better off filling that 1.5" with a continuous layer of 3/4" polyiso strapped in place with 1x4 horizontals for hanging the sheet rock.

Alternatively using 2x2s 16" o.c. and splitting & compressing R15 batts would be higher performance and lower cost for that layer than 1.5" EPS + 2x4s.

The interior side of the 2" EPS is at risk for accumulating excessive moisture in the proposed stackup. It will need an air tight vapor retarder either under the wallboard, or between the 1.5" deep layer with the horizontal 2x and R4 EPS(or compressed split batt) and the 2x4 studwall layer, since the exterior 2" EPS isn't sufficient for dew point control for R13 + R4 in US climate zone 6.