Identifying Underlying Problems with Spray Foam Installation

Hey all,

Sorry to share another potential spray foam horror story, but I’m hoping ya’ll who have seen a lot of this can put in your two cents.

We are working on our old attic in Washington DC. Just had vermiculite removed from the floor, and then 4 inches of closed cell foam applied to the roof and gable walls. The rafters are 6 inches deep. The contractor has stated that they used Natural Polymers brand closed cell foam, and sent over this product info:

The guys spraying failed to use proper ventilation during application, despite my repeated questioning of them and the company office. They assured me that 24 hours with the windows open and bath fans running would be plenty of time to remove the foam odor. Of course it wasn’t. When the smell was still overwhelming after 48 hours out of the house, I got the company to set up an exhaust fan. It ran for 1 full day on the main level, then we moved it up to the second floor, and finally at my suggestion they placed it directly in the attic and opened up the duct at the gable vent to allow fresh air to come in.

The fan has been running for 72 hours, and the smell has definitely improved. The manufacturer says the contractor made a major mistake not following their ventilation guidance, but as long as the foam is of good quality, post work ventilation should address the problem, and they’d expect the smell to be unnoticeable after a week. The contractor claims it doesn’t seem strong to them anymore, but they have left the fan running and have offered to cover our rental costs while we remain out of the house 4 or 5 days longer than expected.

I’d like to find a third party who specializes in inspecting this work who can help me get a grasp on whether ventilation was the only mistake, or if there are underlying problems with the foam. I’m probably overreacting, but I’ve got an infant who has to sleep right below this stuff, so I’m not sure I’ll even be fully satisfied just by the smell greatly decreasing.

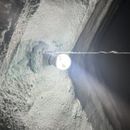

I’ve attached some pictures, perhaps ya’ll can assess the work from afar and let me know if you see areas I should be digging into. It appears quite uneven to me, and I don’t know if the variance in textures I’m seeing could mean errors in the mixing/ application process that will have long term toxic impacts. Also if anybody knows of a company/individual in the area who could inspect this work, I’d appreciate the recommendation.

Thanks in advance,

Gennaro

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'm so sorry you are dealing with this.

Picture number 2 looks pretty bad to me--what surface is that?

It looks like the weather in DC on Dec. 2nd was pretty warm, 50 to 65 F, so that at least avoids one of the classic problems. But there are still plenty of things that can go wrong.

Thanks for taking the time Charlie.

It was around 50 degrees this past Monday. I spent most of the day hovering near the job site stressing. The second photo is the roughest looking rafter bay I could find. The gable walls are quite smooth, as are many portions of the roof, but there are a few areas - particularly near the HVAC where the attic is more cramped - that have a rough texture like that.

The project manager has made a few visits and is confident that the foam is curing properly. I’ve pressed him many times about why ventilation wasn’t used, and he has stated that with jobs this small (the attic is under 300 square feet) they rely on windows and that they have never experienced the odor lingering this long.

If they say they have never experienced it lingering this long, that seems to me to be a clear indication that something went wrong--and the problem isn't just the inadequate ventilation during application.

Had the same thought myself. But I suppose to be more clear: he doesn’t think the smell that I’m complaining about is out of the ordinary, “different people have different sensitivity levels,” etc. etc., and what hasn’t happened before is a customer having this strong of a reaction to it.

I have been talking to the manufacturer, and they are trying to confirm on their end that the product the contractor says they used is indeed what was applied. I guess the only way to be 100% certain that it is properly cured is to have testing performed.

I have a pretty sensitive nose and can smell most exposed spray foam months or years after installation, but it's not so strong as to be offensive, just a slight sweet odor as you mention. Uncured foam has a stronger smell; some say it's like fish but if you're finely attuned to what fish smells like, it's not the same--more like ammonia.

It looks like the foam may have also been painted with a white, intumescent paint? If so, the paint will slow the outgassing process, but the foam should still cure/outgas relatively quickly. It is also possible that the paint has its own odor. Again, that should dissipate "quickly." In my experience, the installers get desensitized to the smell, so they won't think even strong odors are unusual. You are entering from the "clean" outdoors and are not desensitized, so you notice it more. The difference between "noticeable" and "unhealthy" is not well defined by manufacturers or anyone else. I personally notice a characteristic odor in spray foamed areas even after a few weeks, but I don't consider it "bad" after a day or two in most applications. When it's REALLY "bad," you usually know it right away. To me, if there's improper curing, I notice it as a bad fish smell or something similar. That doesn't hardly even fade with ventilation after a week or two. Again, just my reaction. If your ventilation helped considerably and the foam is firm to gentle but not crunchy/crumbly, it probably cured correctly. If you want to dig deeper, the manufacturer may have recommendations on lab testing that could be done on a sample to tell if there's uncured material embedded in it.

Thanks Peter.

I decided to skip the paint for now, since I’d read about the coating causing it’s own problems and I wanted to make sure the foam was right before putting anything else on there. And it would have increased the project cost by about 30%.

I wouldn’t describe the smell as fishy (and as a chef, I’ve been around a lot of dead fish) -

more chemically, sort of sweet smelling. The ventilation has definitely helped, but I think the real test will be when the fan is turned off and we turn the hvac on. We tried turning the hvac on briefly after 1 day of forced ventilation (when the contractor said we should) and the smell immediately was more noticeable, plus our indoor air quality monitor voc levels spiked.

Deleted

It may not be a bad idea to pick up an IAQ monitor, one that can measure TVOCs and start documenting the levels. It could be used to actually measure concentration levels beyond your nose test.

Thanks chicagofarbs

I picked up an Airthings Wave Plus the next day. Have been moving it around to get an idea of the levels. With the fan running in the attic, levels are the lowest I’ve seen them (around 120) in my son’s room. When we turned the hvac on the other day the level spiked from around 250 to 1200. Of course it doesn’t specify what VOCs they are, and I don’t have a baseline for the area before the work was done.

That spray foam looks like it cured OK to me as far as I can tell from the pics. The first pic looks excellent, the second worst, and the rest are "normal". The worst one I'd check for gooey-ness or excessive crumbly-ness, as both are signs of incomplete (gooey) or improper (crumbly) curing.

They should have masked off the base of that light fixture prior to spraying.

To exhaust the stink, you can't just randomly run fans. What you need is crossflow ventilation, which means "in one side and out the other". I would put a fan blowing OUT from the attic to the outdoors, which will depressurize the attic. This means any leaks leak IN to the attic, not OUT from the attic to your home where your living spaces are. Let air come IN from somewhere convenient that is as far towards the opposite side of the attic from the exhaust fan as possible. The ideal scenario is the exhaust fan blowing out on one end of the attic, and the air coming in on the opposite end. This makes the airflow go through the ENTIRE attic so that there are not dead spaces, and is most effective for exhausting all remaining smell.

The usual way to check cure is to take a piece of steel wire, like the straight part of a wire coathanger, then push it through the cured foam all the way to the wood sheathing. The wire should take about the same amount of force to push as it gradually goes all the way through the foam. There should be no "it got easier" or "it got harder" moments as you push it throught the foam. The wire should come out without any sticky residue on it too -- if it has sticky good on it (aside from maybe a very thin film), then you have curing problems. The tiny hole you make with this test isn't usually a problem, but if you're concerned you can inject a bit of canned foam or even some caulk to fill the hole.

I usually tell people to wait a weekend with the ventillation running to get things to a good condition for you to come back in. You'll probably still smell it a little, similar to "new car smell", but it should NOT be overpowering after that much time. If you're having extra issues, try ventillating for a week and see if things improve -- they should.

Bill

Thanks for the detailed response Bill. I’ll go ahead and do the wire test on that most uneven area tomorrow.

At this point, the ventilation is set up as such: the 4 inch duct seen in the first picture has been severed to supply fresh air at the one gable. The contractor’s exhaust fan is in the center of the attic, pointed toward the other gable wall. The duct from that fan runs down the attic ladder to the nearest window on the 2nd floor. Because of this duct setup, the attic door is wide open. And because the duct is at its maximum length, the fan can’t be placed any further toward the opposite end of the attic. Is it worth breaking through the foam at the other end of the attic to install the fan there instead?

Further, we have a tiny crawl space under the first floor half bathroom that they encapsulated with foam and then promptly sealed shut rather than allowing to ventilate at all. I’ve opened the hatch and set up a box fan blowing out because that’s pretty much all I had on hand, and the quality control guy assured me the one fan he brought would solve all our issues.

Deleted

Hey Bill,

I went ahead and poked a few spots. Nothing gooey, which I was glad to see. The coarser areas were more difficult to penetrate, and I would hit depths that it felt like I had to crack through to continue going up to the sheathing (pic1). No pieces crumbled from the ceiling or anything like that, the stalactite in the picture has been there the whole time. The interior just seemed more brittle.

There is one strange spot in the crawl space (2nd pic) It’s a sort of bulbous patch that they seem to have added a streak of canned spray foam to (the light yellow part). It feels essentially hollow when penetrated with the hanger, and sounds that way too when you tap on it. Is it possible for the material to just overexpand and blow out or something like that?

Worth bringing up any of this with the project manager? The smell continues to be reduced it seems, going to try running the hvac today with an added layer of carbon filter to hopefully reduce the smell.

Thanks again

Sometimes you'll get a void or two that the crew will typically fill in with some canned foam when they double back to check the application. That's not usually a problem, I wouldn't worry about it.

The crumbly spot might be where they started (or stopped), so that would be where they first dialed in the mix. Since you don't have any gooey spots, you shouldn't have any of the nightmare scenario -- gooey is where smell comes from on bad installs. Brittle is just less than ideal from a structural and R value perspective, but isn't usually a problem in terms of excess smell.

I think your ventilation is less than ideal. If you can't do the "in one end and out the other" with the fans, add a second fan positioned to "swirl" the air in the room, making a sort of vortex around the outside walls. The goal is to have NO stagnant areas, you want the airflow passing over ALL of the spray foam for best results. The stirred air will bring the contaminants out where the exhaust fan can get them and blow them out of the space.

Remember: the key here is to have moving air EVERYWHERE, ideally with the "in one end and out the other" path, but next best is as much seperation between in and out as possible with a stirring fan to make sure there are no dead spots around the periphery. Dead spots are where the smell will linger.

Ultimately what you're doing is lowering the concentration of solvents in the air which speeds the offgassing process.

Bill

By any chance was it Southland who did the spraying?

It was Fairfax Insulation

Deleted

I’d like to find a third party who specializes in inspecting this work who can help me get a grasp on whether ventilation was the only mistake, or if there are underlying problems with the foam. I’m probably overreacting, but I’ve got an infant who has to sleep right below this stuff, so I’m not sure I’ll even be fully satisfied just by the smell greatly decreasing.

To directly answer this question: in the Northeast, the top spray foam consultant I work with is Henri Fennell; he is based out of Vermont, but travels all over.

https://polyurethanefoamconsulting.com/

He has written an excellent JLC article on the basics of troubleshooting SPF:

Avoiding Problems With Spray Foam

To make sure you're getting a good spray-foam installation, choose a certified contractor and run regular material tests

https://www.jlconline.com/how-to/insulation/avoiding-problems-with-spray-foam_o

As full disclosure--he is a good friend... and as a warning, he is pretty busy.

Another SPF consultant I have heard about is Mason Knowles, out of GA:

http://masonknowles.com/about/

He also wrote another excellent JLC article:

Troubleshooting Spray-Foam Insulation

A lot can go wrong with a two-part plastic insulation that is essentially manufactured on the job site as it's being applied. Here's what to look out for

https://www.jlconline.com/how-to/insulation/troubleshooting-spray-foam-insulation_o

As an overall last comment: setting up a ventilation system that exhausts from the attic, drawing its makeup air from the house, may do a good job of "containing" any odors associated with spray foam in an unvented/conditioned attic assembly. I don't know if that's the one place where it is an issue, or if you have SPF elsewhere in the house.

Thank you Kohta

We returned to the house today, and with the ventilation removed and the hvac running the odor is at about 25% the strength of what it was 5 days ago. I think that contacting one of the experts you mentioned would probably give me the ultimate peace of mind, but is probably overkill at this point. I think we’ll probably give it a few weeks with us actually living in the house and see how things develop. If long term ventilation is needed, there is also a small unvented crawlspace to consider.

Thanks to everybody who offered their advice here, you all have been a big help.

The problem isn’t fully resolved yet, but things are significantly better. If the contractor had just ventilated properly from the start, this probably could have all been avoided.

Even with proper ventilation at install time, you still have a few days of smelliness. I find that the smell mostly dissipates within 2-3 days or so, which is why I recommend doing the application on a Friday and then going out of town over the weekend with some windows cracked open. If you have SIGNIFICANT smell a week or more after the application, then you know something wasn't done quite right, even if that "something" was just insufficient intitial ventilation.

Bill

A brief update:

Smell has continued to decline until today. Temperatures dropped below 30 outside overnight for the first time in a while, and our heat pump’s backup heat system kicked on. The odor is noticeable again on the upper level, and our indoor air quality monitor is reading way higher VOCs than it had been the last week (1200ppb, up from around 200). Not sure if this is just going to be the norm when the attic is hot, or if the backup heat coil is burning something off.

Also, the contractor now says that the foam installed was BASF Spraytite, subbed in due to supply chain issues. They have provided lot numbers for the A side and B side, and I’m trying to coordinate with the manufacturer to verify.

I'd suspect something from the heating coil. Remember that those VOC meters are not selective -- they read pretty much anything they see, so they just say "it's high", not "it's high BECAUSE OF X".

Colder temperatures should result in less offgassing, so if the meter's reading ticked way up when the heat kicked in, I'd blame that increased reading on something related to the heating equipment and not the insulation you've been monitoring.

Bill

Seems to me when we read about these spray foam problems every few months but the end result never gets posted here.

From what we see it seems the companies plan is to get you to chase you tail and do nothing for as long as possible while hoping you will get frustrated and go away without them spending any money.

At some point the customer come to the realization they are wasting away there live talking to the company that is never going to do anything until they are on the courthouse steps the day of jury selection. My guess is on that day they pay people to go away if they will sign a nondisclosure agreement. My guess is the first day people meet with the lawyer they are instructed to stop posting about what is happening before any settlement and a NDA prevents them from posting afterwards.

Seems to me you can decide to live with the problem and hope it gets better over time or lawyer up and make them fix it. It seems to me there is no middle ground were they rip out insulation and replace it out of the kindness of their hearts or because it is the right thing to do. Maybe it does happen with an NDA but I am guessing not so much.

All we can do is guess at how things ended as I have yet to read if any of the sad stories had happy endings.

Walta

Good summary. It would be good to know the long-term outcomes. You've pretty much predicted it and its not pretty.

The Happy Endings are when people decide not to do closed cell spray foam in the first place? Its just not worth the risk, or the higher cost, when usually you have less risky and more affordable alternatives (that are usually more environmentally friendly as well).

The two cases I'm familiar with: One who sold his home at a loss, who thought he was "too sensitive" to the foam, so had to leave, and wasn't going to hide the defects from a buyer. The other who was conned into believing that closed cell spray was the best product available in any situation, and spent a small fortune on a spray foam contractor who "educated" her on the superiority of closed cell spray foam over any other insulation alternative (which he would not consider providing due to their claimed inferiority). Last job at her single family home, the contractor convinced her to add spray foam between attic rafters for $7,000, to increase the attic R-value of existing insulation on the attic floor and encapsulate the attic containing HVAC equipment. No alternative was considered acceptable to the contractor.

How many recurring problem installs and sad stories do we have to read here? Closed cell spray foam typically is just not worth the risk or the cost, if you have a realistic alternative. Why not enumerate those situations where there's no good alternative to closed cell spray foam, and otherwise recommend the alternatives, and recommend avoiding closed cell spray foam? Consumers typically aren't going to figure out this for themselves. Then often end up posting about noxious odors, valid concerns about their family's health, anxiety about how to address the issues, and substantial financial costs to fix the problem odors or reduce health concerns. Hiring an attorney isn't discussed when other insulation alternatives are described. Exotic insurance policies aren't discussed in other articles when other insulation alternatives are described. Just closed cell spray foam articles and complaints, over and over and over. We hear that most spray foam jobs work out well, and that we only hear about the small percentage of bad installs. But even then, is it worth the risk? Is it worth the extra cost? Doesn't seem so, from the unfortunate cases that don't work out well.

We don't often read about people concerned about their health, or on spending large sums of money fixing troubling problems with poorly installed cellulose, or rock wool, or fiberglass, or polyiso, or EPS, GPS, .... Why not recommend these alternatives and clearly suggest avoiding closed cell spray foam except in certain limited specific situations??

Robert,

I couldn't agree more. Apart from SIPS I can't think of another building product or assembly that can cause such irremediable problems.

There is certainly a place for it in some situations, but before choosing it I think customers need to be made aware of the risks, and contracts should include clauses providing for independent third party arbitration in the event things goes wrong.

Spray foam does seem to come with that “Did they do it right?!” factor, which is why I asked Scott Gibson to write this article: Spray Foam Gone Wrong to help people start sleuthing problems. The expert he used as a source, Henri Fennell, might be a resource for you.

Small update since it’s been a while and there’s been some more posts…

After supplying the lot number for the chemicals to a BASF distributor, I was informed that they actually matched a demilec product. Got in touch with them in the hopes that they could at least verify what had been installed in my home and perhaps inspect it/test the foam, but they never got back to me.

Meanwhile, the installer has gone out of business. At least they won’t be messing with anybody else, but there’s just about no chance of getting any more info out of them - not that they kept good records anyway.

I no longer notice an odor in my home, and it is significantly less strong in the attic itself. As yet I haven’t noticed any degradation in the foam, nor any health side effects for us. It does keep the attic significantly cooler, but has not seemed to help much at all with the overall comfort of the house.

I’ll probably always be somewhat skeptical after the stress of the few weeks following the installation, and due to all the uncertainty caused by the installer lying about the product/installation protocols/etc. However, at this point it doesn’t seem worth going down the rabbit hole any further. I did get in touch with Henri, and he seems eminently qualified to handle just about any spray foam situation, but I’m just not sure he’s needed here. Perhaps if I take another swing at improving the efficiency and comfort of this house I’ll have some other contractors take a look at the work done so far and get their read on it.

Thanks to everybody for their advice.