Another Cathedral Ceiling Question

Hi All — thank you for all your guidance and information. I’ve read a lot of the questions on roof insulation assemblies and cathedral ceilings but still have a couple questions. I know there are a lot of options out there (a good and a less good thing).

I have a 12:12 roof in Zone 6 with 2×12 rafters. I know many of the *best* ways to insulate the roof, though I’m trying to find an option that’s more turnkey and avoid any issues with roofing crew rejecting my details or not doing them right — as it’s a somewhat remote build with limited labor. So for that reason, rigid on top of the sheathing with an additional sheathing layer is low on the list. Spray foam is also low on the list because of the high cost.

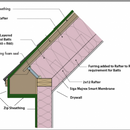

At the moment, I’m leaning towards a traditional 100% fluffy insulation in a 2×12 cavity. I would fur out the rafters, use Rockwool, and probably do 2x layers of Batts vs. blown in because I would be able to DIY it as an easy project. I’ve seen this assembly on this site and others before and it’s certainly nothing new.

However, my first question: Can I design the above as a hot roof that dries to the inside through a one-way vapor membrane like Siga Majrex? All the examples I’ve read about note a ventilation channel and an assembly that dries to the *outside*, but I have two dormers in my design so drying to the inside seems to be the smartest and safest, if it’s permissible. The first attachment has these details (*altered from the version that has the ventilation gap — so ignore the gap in the image).

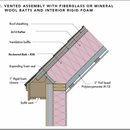

If this doesn’t work, I’m considering a version #2 that has R38 Batt of Rockwool in the cavity, a ventilation baffle, and a layer of rigid foam on the inside. This assembly would obviously dry to the exterior. This assembly has a lower R value but does have continuous. I suppose I could move to a 2×14 rafter to reach a similar insulating value, but I haven’t yet run the calculations on those costs yet.

So, in addition to feedback on if the first assembly works — would any of you choose the second option over the first for any reason? Again, looking to find a an efficient, durable, straightforward option that doesn’t scare away trades — which I realize, is part of the unicorn problem that this entire site addresses often.

Thank you,

– Sean

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Roofs with only fluffy insulation in cold climate zones need to be vented, as decreed by code and by building science. Drying to the inside only happens when the interior is cooler and drier than the exterior, which isn't often in CZ6. Variable permeance membranes help but in most cases they can't guarantee a safe assembly.

Echoing Michael's thoughts--doing an unvented cathedral roof (i.e., no ventilation chutes) is only allowed by code in cold climate zones if you are using cavity spray foam, or rigid insulation on the topside of the sheathing. There are no code-permitted unvented roof assemblies that are 100% "fluffy insulation" (a.k.a. fibrous insulation, blown in fiberglass or cellulose) for cold climates.

BSC's research for DOE in our test hut showed that these all-fibrous insulation assemblies *can* work if you add things like diffusion ports and variable-perm interior vapor retarders, but they're way too risky and finicky to allow in the code. Basically, in our test building, we got them to work on the second time around, which is a luxury that most builders do not have. See the slides below.

Northeast Building Science Symposium (Connecticut): Edge of Risk Assemblies - Double Stud Walls and Fibrous Insulated Cathedral Ceilings

June 21, 2023

2023-06-21 CT Ueno-Edge of Risk Assemblies Handout.pdf

https://buildingscience.com/sites/default/files/presentation-docs/2023-06-21%20CT%20Ueno-Edge%20of%20Risk%20Assemblies%20Handout.pdf

Kohta Ueno

Thank you both. I figured there was reason I never saw it as an option, and this makes sense. I'll plan to vent to the exterior with baffles and vent -- choosing one of these two options.

Thanks--

here's an option that i'm considering, but it isn't the simplest, and likely not every contractor will love it

buildzilla,

It yields a well performing roof though. When I first saw it, thinking of myself building it I balked a bit, but those here on GBA who have done it say my misgivings about the difficulty are over blown.

an architect that i discussed that strategy with seems to think that a scissor-truss strategy is more cost-effective (i guess labor wise?) at the cost of some ceiling height, but say the inner angle is 6/12 pitch, seems like a good deal of blown-in would have to be dumped in to get r-50 at the inner peak without worrying about slumping