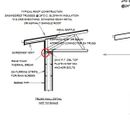

Airtight drywall/thermal break w/icf

I have this detail in my plans and basically have two questions. One is on the airtight drywall approach. Given the exterior walls are icf, my main areas to pay attention for sealing the drywall would be the top plate to truss connection. I’ve seen the approach of using sill seal foam rolled out and stapled into place, is this a decent approach?

Second question is on the thermal break (albeit small) on the top plate. The drawings call for a double plate of 2×10 and the walls are 11&1/4″ wide. The way I see it, I can either stack the block, and maybe cut to height on inside, set the top plate and cut the foam on outside flush. In this scenario though, I’d have to rip down the top plates a bit (~5/8) and not sure if inspectors/engineers would care?

Second option would be to rip 2″ wide rigid foam in 3″ strips and adhere to the outside of the top plate. Thoughts? Ripping foam sounds like less work than ripping 2×10’s aside from climbing a ladder to install it, so I think I just answered my own question.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

If you are installing the drywall without any strapping, the best way I've found of connecting the wall and ceiling air barrier is with a wide piece of flashing tape.

Peel back 1/2 the backing on the flashing tape and cover the top of your wall, let the other half with the backing in place hang to inside. Install your roof structure and put blocking between trusses at the walls. Staple the tape to this blocking, peel back the backing when you go to install your drywall. The peel and stick now gets sandwiched between the blocking and the drywall creating a very solid seal.

That does sound like a good idea, plus I could see the sill seal being damaged easily by drywallers vs peel and stick.