Airtight drywall

I want to caulk and foam all joints in my framing prior to hanging drywall. Is there a difference in latex caulking and is there a best one when it comes to providing an airtight seal for air barrier? I will be hanging glued and screwed OSB on the interior side of the studs for stiffening an old house, will the same caulk and or gaskets be fine to install the OSB as it would on drywall.

When construction adhesive is used on the drywall or OSB, will that effectively act as an air seal on the faces of the framing or should one use gaskets and if so, what is recommended. I have used Denarco gaskets years ago, are these still advisable? Recommendations of sealants that have good value and performance would be great.

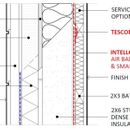

Lastly, when a INSULATED service cavity is used on the interior of the the sealed exterior walls ( mine have a OSB layer to stiffen a squeaky house, should the Intello or such be against the OSB and the service cavity built on top of it or should the smart wrap be directly behind drywall.

Attached is a drawing from:

https://foursevenfive.com/the-service-cavity-making-airtight-construction-easy-2/

Thanks for all past help.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

John,

First of all, here are two resources of information on the Airtight Drywall Approach:

Airtight Drywall

Video: How to Hang Airtight Drywall

In his video on GBA, Myron Ferguson shows how he uses ordinary latex caulk when installing airtight drywall. If you can afford to upgrade to Denarco gaskets (or gaskets from Conservation Technologies), you won't regret the upgrade.

If you want to use a layer of OSB as an air barrier, you might want to use tape, not caulk, to seal the OSB seams. High quality tapes include Siga Wigluv, 3M All Weather tape, or Zip System tape. (For more information on tapes, see Return to the Backyard Tape Test.)

Finally, you might want to consider the fact that some brands of OSB are not airtight. For more information on this issue, see Is OSB Airtight?

Thanks for the info. I did not know about all OSB not being equal in AT respect, great info. I have previously watched the AT drywall video and I was wondering if he indeed was using latex caulk. My question is there a reason to have a more flexible caulking than latex ( Sika Sikaflex-201 US, Tremco Dymonic FC Polyurethane, both $6.00 a tube or CONTEGA HF $13.80 tube= ouch! ) on the framing and connections.?? Just curious from your experience.

I also want to glue ( and air seal if possible) the interior structural layer of OSB on the inside of the existing wall and wondered if you could make recommendations to an glue that could do both? I will definitely tape the OSB joints after install with one of your recommendations- thanks.

John,

Ordinary construction adhesive will work fine for gluing the OSB to the framing.

In general, more expensive caulks will probably be more flexible and durable than less expensive caulks. Whether expensive caulk is needed for airtight drywall is a judgment call. The information below comes from a Fine Homebuilding article called "Caulk This Way."

Arylic/Latex

Often the least expensive

choice, these water-based

caulks cure by evaporation.

Consequently, they can shrink

by a quarter to a third of their

volume before they’re fully

cured. They hold paint well and

usually can be painted within

four hours. Most aren’t as

flexible as many other sealants,

but they’re a good choice for

filling small gaps between

interior-trim pieces.

Butyl/Rubber

The original modern sealant,

butyl dates from the 1920s. It

cures through the evaporation

of organic solvents, shrinking a

quarter to a third in the process.

Butyl is sticky and can be harder

to tool than other sealants,

but it can be used in freezing

weather. Best used outdoors

because of its odor before

curing, butyl is less common in

residential construction than

other sealants.

Polyether/Silicone

So-called STPE (silyl-terminated

polyether) sealants are similar

to and sometimes superior to

polyurethanes. Relatively new

to the U.S. market, STPEs have

been used in Japan for decades.

Based on polypropylene glycol,

they cure by reacting with water.

The cure rate is much faster

than that of polyurethanes, and

STPEs can be painted sooner.

They can be used on damp

surfaces and in below-freezing

temperatures, making them a

good choice for outdoor use.

Polyurethane

Although urethane cures by

reacting with moisture, it

shouldn’t be applied to wet

surfaces or when rain is in the

immediate forecast. An excess

amount of water can cause

a reaction that releases an

undesirable amount of CO²,

which can cause the sealant

to froth and compromise its

ultimate strength. Although hard

to tool, polyurethane sealants

are paintable, long lasting, and

abrasion resistant.

Polyurethane/Silicone

These SPUR (silyl-terminated

polyurethane) hybrids have

characteristics similar to STPEs.

Like STPEs, SPURs rely on

groups of a long-chain polymer

(in this case, polyurethane) for

the backbone of the sealant,

and groups of a second polymer

(silyl or silane) for the ends. The

long-chain polymer provides

both elasticity and cohesive

strength, while the silyl endcaps

provide adhesion.

Silicone

Early versions of silicone caulk

had a so-called acid cure and

released a vinegar smell. Modern

silicone cures by reacting with

moisture and gives off very

little odor. Silicone bonds at a

molecular level with glass, making

it a good choice for frameless

shower doors and tile. It doesn’t

take paint, and not even silicone

sticks to where silicone has been

used before, so recaulking usually

requires mechanically removing

some of the previous substrate.

You also might want to consider EPDM drywall gaskets from Conservation Technologies. No mess, can be installed long before drywall installation, permanent flexibility.

http://www.conservationtechnology.com/building_gaskets.html

Dan,

I made the same recommendation, and provided a link to Conservation Technologies, in my first response. (I'm glad we agree.)

Thanks for the information. Can anyone give me a response on the last part of my submission if possible.

"Lastly, when a INSULATED service cavity is used on the interior of the the sealed exterior walls ( mine have a OSB layer on the inside surface of the studs to stiffen a squeaky house?"

Should the Intello or such be against the OSB and the service cavity built on top of it or should the smart wrap be directly behind drywall?

Thanks

Jon,

OSB is a variable-permeance vapor retarder. It's already a "smart" vapor retarder.

If your only source of information about the need for the Intello vapor retarder comes from people who sell Intello vapor retarders, you may want to ask others for advice. The OSB can be your air barrier (as long as you don't choose a leaky brand of OSB), or the drywall can be your air barrier -- and the OSB can be your smart retarder. In other words, you probably don't need any Intello.

For more information on service cavities, see Service Cavities for Wiring and Plumbing.

I'm much better at advice than reading.

You might also consider using a spray foam to seal the sheetrock to the framing. That seems to be what our modular home manufacturer did for the double-framed four main module walls in our northern New Jersey passive house. We passed our blower door test with no problems.

The insulation in the cavity is densepack cellulose. The outer sheathing is Zip System. And we have 2-inches of Type 1 EPS foam over the Zip System.