Air sealing at the mudsill

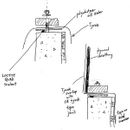

After watching “Passive House Video — Episode 2″ I’ve been thinking about doing more to stop infiltration at the mudsill in our new house build. In the video there are several layers between the foundation and the actual mudsill including a copper sheet, a sheet of plastic, a gasket, and some sealant goop. In one place on GBA someone said that the common polyethylene sealing strip that comes in rolls is fine if you caulk the seam in the basement. But I like some of the ideas in this video. I’d prefer to keep poly sealing strip but add a bead of sealant between it and the foundation just to cover some of the worst irregularities in the concrete surface. On top of the sealing strip I’d add a strip of tyvek overhanging a few inches on both sides of the foundation. Inside the basement the tyvek would be sealed/taped to the 1” layer of XPS lining the basement wall. Outside the tyvek would be sealed/taped to the exterior sheathing so that the next layer of tyvek would shingle-layer over it. I’ve attached a rough sketch. I would think adding the bead of sealant and the layer of tyvek is a vast improvement over just the sealing strip. Any thoughts? Pros and cons? Thanks for any insights.

House data — double stud wall, no exterior insulation, plywood sheathing, climate zone 5 (Lancaster Co, PA)

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Acoustical sealant both sides top and bottom , 2 or 3 beads and around bolts will usually seal it up pretty well. GLAD to see someone closer to home building smart! I visit your area OFTEN!

Also, your tyvek detail has never worked for us , we couldnt get it to seal and stay in place at the same time.

Could you elaborate a little more on your experience, why it wouldn't seal and why it wasn't staying in place? Would a different material work better, like in the video I think they used vinyl like the kind used under a concrete slab? Somehow they made it work in the video, so I'm wondering what the issues are that you encountered. Thanks

Its just another thing "in the way" to deal with is what i meant. You're fighting for a good airsealing job there and the mor you add the complicated it is. It CAN be done. Done afterwards is just a lil easier

I would replace the tyvek detail with a liquid flashing on the outside.

If you insist on keeping the tyvek for lapping over the interior insulation or other reasons, just cut it in plane with the exterior.

Keep your beads of polywhatever for some redundancy, add this with the liquid flash should be a well air sealed mudsill.

I don't think the shingle layering of this tyvek piece and the tyvek house wrap/sheathing WRB would provide any benefit.

If you're uncomfortable with water running over the flashed mudsill assembly, you could run a strip of PT butted up to the bottom of the plywood sheathing, or do it before sheathing, covering the mudsill, and have your house wrap overlap this.

Are you taping or flashing your plywood seams?

We are planning on taping the plywood seams.

As for where the sheathed wall meets the basement wall, I'm not sure on all the details -- it's been a long time since we built our last house. Most diagrams I see have the sheathing proud of the basement wall but not overlapping it. And as far as I can tell the bottom edge of the sheathing actually remains exposed in the finished house. Is this standard?

So if I apply liquid flashing, won't it overlap an inch or two below the top of the basement wall? If so my next question is will siding cover over this? -- we are planning to use vinyl siding, which is very common in this area.

I can't answer the former, but I can say I wouldn't want to leave it exposed. Exposed leaves it prone to air, insect and water infiltration. I would butt pressure treated to it in this case, personally.

An inch or two overlap of the flash onto the concrete yes, the siding should be able to cover this.

Use some painters tape when applying the flash to peel off after and give a clean edge if you like, in case it is exposed, but it's best to cover it. Use black just in case.

There seem to be many ways to address this issue, and most seem to be complicated and messy. It seems that an EPDM gasket combined with exterior taping of the foundation to wall with something like Delta Multiband should be robust and straightforward. Of course exterior taping close to the ground requires careful prepping, but this approach to air sealing seems simpler.

But I'm not an experienced builder, so maybe I'm overlooking some things (like the anti-termite strip).

We used an epdm gasket. If you're paying for labor, it's pretty cheap.

I would keep my eye on material compatibility as well; sometimes you can get a reliable answer from each of the material manufacturers involved but sometimes you just need to stick them together and monitor "over time." I put this last in quotes because, yes, the question will be how much time? And then how to test? How does 30 days sound and then stress it with what forces you think the materials will "see." Sounds like we need a Wingnut Test Facility protocol...

Peter