Air Barrier for Unvented Roof Assembly

Hi all. I’m in the process of building my house with Faswall blocks, a type of ICF. All blocks are placed and filled with concrete and we’ll drop in the roof beams in a few weeks. I’m trying to get my roof assembly dialed in and have several questions. I’ve read the articles posted here on rigid foam roof insulation as well as on buildingscience.com and have consulted with a few friends in the energy efficiency/weatherization business. I still have few questions as this is my first build and I want to get it right. I live in Wenatchee, WA, which is climate zone 5, at 1,400 ft elevation. Snow in the winter is hit or miss at this elevation. Some winters, such as this past one and the winter of 2018-19 bring 2 foot snow loads and other winters have minimal accumulations.

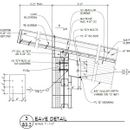

Following my structural plan and Joe’s “Robust Unvented Roof” here https://www.buildingscience.com/documents/insights/bsi083-mea-culpa-roofs, I have the following layers for my roof assembly, from bottom to top:

beams

per the architectural plans, the minimum value for this roof is R-38 (because it’s a vaulted roof, according to my architect).

My questions are:

1) to create an air barrier, should I tape the seams on both plywood layers, or just the top or the bottom layer? Joe’s assembly only has plywood on top of the foam and he recommends taping the seams or applying a fully adhered membrane.

2) should I tape the poly-iso or the EPS seams? If so, with what?

3) should I vent the roof to account for ice dams?

4) the standing seam metal roof screws will penetrate the top layer of plywood and into the EPS rigid foam layer. Will the gaskets provided with these screws provide an air barrier, or should I take a further precaution?

I’ve attached several photos of the roof detail.

Jason Schilling

Wenatchee, Washington

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'm not sure the first layer of plywood has any purpose other than air sealing here, is that right? The 2x6 T&G provides the structure, and the rest are the /water/air/vapor/thermal barriers, which is why he doesn't have plywood there.

For that matter, there's lighter, more air tight, and more/less permeable materials that could be used here at cheaper cost, not to mention saving on the tape / nails / back. The self-adhered membrane is a foolproof way to accomplish this, but a good job on sealing the polyiso and eps could probably work fine too.

Good point Kyle. The structural engineer mentioned something about that bottom layer of plywood being "part of the diaphragm." I could delete that layer and replace it with the self-adhered membrane.

I would recommend consulting with your engineer before you delete a layer that they say is part of the diaphragm!!!

It may be that the 2x6 T+G isn't adequate to create a diaphragm to transfer the lateral loads across the roof and that the plywood is an important part of the structural system.

It is the T&G that will give you problems for air sealing. The air control layer is above the T&G, so you need to figure how it will tie into the air barrier of your walls to make the air tight plane continuous.

Jason,

If you can convince your engineer to forgo the lower layer of plywood, I agree with Kyle it's not doing much. I also agree with plumb_bob that the t&g is your most problematic layer from an air sealing perspective. Not in the field, where it can be covered by a membrane, but at the edges where it is continuous over exterior walls. You need to come up with a strategy to seal the boards there and make the air-barrier continuous with your walls.

If your primary air-barrier is a membrane on the t&g (or the lower plywood), I don't think it's worth sealing any of the layers above that, nor would I worry about the roof fasteners.

Are ice dams typically a problem in Wenatchee?

Thanks for the response Malcolm. I will check with the roofing supply company in town about ice dams. As for the T&G/Wall interface, I was planning on using Siga Fentrim tape for that on the interior and exterior.

Jason,

The problem with the t&g as it goes over the exterior walls is stopping air-leakage through the grooves, and below the boards which usually have a mitered edge. The boards should be bedded in a flexible sealant, and a bead put in each groove during installation.

A better solution is to make them discontinuous, by starting and stopping them at the walls, and leaving a gap that can be air-sealed, but sometime the structure makes that impossible.

Thanks Malcolm. Is there a flexible sealant that you would recommend for this application?

Jason,

It doesn't need to be particularly flexible. I'd use clear silicone, which is very durable over time.

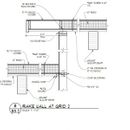

In detail 8/S3.2, it looks like the T&G boards are continuous and provide the structure for the overhang. If they need to be continuous, you have to do the fancy sealant work Malcolm is talking about.

If you can make them discontinuous, your life gets a lot easier, as you can just tape the roof sheathing to the wall sheathing.

Instead of supporting the overhang with the t&g, you could use 2x outriggers above the roof sheathing air barrier to support the overhang, like in Figure 1 and Photograph 3 in this article: https://www.buildingscience.com/documents/insights/bsi-081-zeroing-in

You may need to run this by your engineer to make sure it's all fastened appropriately.

>"plywood (seams taped with Siga Wigluv)"

==>AIR BARRIER

You don't need another air barrier, as long as the edges and any penetrations of your taped plywood are properly detailed. You don't need to separately seal the t & g.

Taping the seams of the top layer plywood as a secondary air barrier is good practice.

What type of underlayment is there for the standing seam roofing?

Dana,

You still need to seal the T&G below where it continues over the exterior walls. The plywood detailed as an air-barrier isn't continuous with the wall air-barrier otherwise.

Dana,

I was planning on using Siga Majcoat, unless you recommend something else. Is a vapor permeable membrane necessary for my situation? The standing seam metal roofing will be directly on top of the membrane.