Asking for help with Heat Pump Equipment Selection

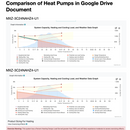

TLDR: Old house is going to have radiant panels and heat pumps. We’ve done some insulating and improvements to windows and now I would like to ask for your opinion on the 4 different heat pump configurations. They are shown in the attachments below along with the NEEP heat pump reports. ;). The screenshots of the spreadsheet is a bit blurry so here is the link on Google: https://docs.google.com/spreadsheets/d/1pV1Qfwo72uflV4MTj0aDJbhd4s_3-K8kfgeHhDkpkj8/edit?usp=sharing The NEEP screenshots below should be good.

Hello everyone…really appreciative of the community here. First time poster…long time lurker! I’d like to have some eyes (and input) on my selection process for Mitsu heat pump equipment….details below if anyone is willing to lend a hand.

My family purchased an 1880’s home with balloon framing, wood siding and are mostly on the happy side of the air sealing and insulation phase. The home is 2 story and has an unfinished basement and unconditioned attic with all 4 levels being approximately 1000 sq ft with a 250 sq ft converted garage off the back of main level. Attic has R-50 (code) and the walls are mostly 4″ bays filled with blown in cellulose with a lot of air sealing. The local Hysterical District prohibits changing out the single pane windows so I built 25 wooden storm windows with 1/2″ insulated glass units/double pane which has been a serious upgrade to the building envelope.

The home is currently served by a 70 year old furnace w a pilot safety device that would keep a bomb disposal expert up at night, a Triangle Tube Prestige 110 (DHW and slant fin baseboard in a converted garage) and an evaporative cooler so old the local university profs are looking to carbon date it. Thank you previous owners.

We had a Manual J done by Energy Vanguard and the total heating load with the unfinished basement is 75K with the cooling loads of 30K. We are Zone 5 (Boulder, CO) with a design temp of -2 and 92. If you subtract the unfinished basement and the converted garage which we do not plan on heating with mini splits you get to 48K heating load for 2000 sq ft. If you add up the heat loads just for the areas where the mini splits will be you get 39K. Also had a blower door test which came in at 7 ACH but it was somewhat incomplete as we have yet to sheetrock one of the ceilings upstairs.

The Plan: DHW and Runtal radiant panels throughout home with a Veissman CU3A boiler (size to be chosen by heating engineer/installer). Six Mitsubishi ductless wall units with 3 upstairs (2 6K in each smaller bedroom and 9K in master) and 3 downstairs to cover TV Room (6K), Kitchen (6K) and Dining/Living/Entry (15k). Having 2 systems should provide redundancies if we have a failure or if the heat pumps need to defrost, etc. I am not doing ducted for a number of reasons…old ducts but primarily I am using the basement for housing work tools and the attic for storage and don’t want to have a large number of ducts and returns running around…yeah, I know this is not perfect.

I am thinking that we would use the heat pumps for mostly shoulder season and for summer cooling and was hoping to size to be 80% to 100% of the heat load based a lot on what I have read here. But that is difficult as the wall units are often larger than the loads.

The Question: I have read countless forum posts and articles extolling the virtues of mini-split efficiency but still am not confident in which equipment configuration to go with. I did get a Manual S but when I plug the recommended Mitsu units into the NEEP calculator I get a lot of low load cycling.

Honestly, I have been looking and working on this for long enough that my head is spinning.

To help I built a spreadsheet with 4 different Mitsubishi outdoor unit configurations…#1 Using two 24K Hyper Units, #2 using one 48K Smart Multi (not sure of any advantage with SM), #3 using 6 individual outdoor units sized for each of the 6 heads, and #4 using one smart multi 36K unit and a regular M-series 24K Hyper heat unit. Looking at the NEEP graphs it seems like putting in 6 heads is the way to go…but that is a lot of work and space….are the multi’s going to be that much worse on efficiency?….they certainly cannot modulate down enough for some of the low loads I have.

I have included attachments below with the spreadsheet and then 4 screenshots of the NEEP graphs for each unit in the spreadsheet in order.

Would really appreciate the community’s thoughts on my configuration and hoping that this exercise will help the next guy as well.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Very rarely does the expense of air to water make sense but this might be a situation where it does because:

1. You’re going with radiant anyway

2. No ductwork

3. Low load rooms where multi splits perform poorly

4. Easy to use a small buffer tank to avoid short cycling

5. Allowing you to install a much cheaper boiler since it’ll only be used as supplementary heating.

Hi Paul. Thanks for the insight. I originally thought about doing radiant using air to water and had a contractor come give me an estimate. I was planning on using Runtal radiant panels with a very small amount of infloor heat where we currently have the flooring up. My understanding was the radiant panels require a supply temperature of 180F and the infloor 100-130-ish. I have looked at the Sanco, Artic and a few others but they cannot meet the temps. Retrofitting the entire house with in-floor heat is cost prohibitive. My thought was to eventually run solar panels to power the heat pumps and rely on the boiler mainly for the coldest days of Colorado winters. If I am missing something in terms of the reliable tech in air to water or if the buffer tank would allow me to get to the required temps I would sure love to hear more?

That was incorrect information. You can use any temperature above room temp with radiant panels, given the right sized panel. However, due to space constraints they are often sized for 120F. In fact, given the current proposed boiler, it seems like the intent is to size them for lower temps (otherwise you will have an extremely expensive low efficiency boiler - condensing boilers NEED low return temps to be efficient). A possible solution would be to size the panels for a temp on the coldest day that exceeds the output of the air to water heat pump (for example 140F) to balance panel cost/size but use a return temp in the air to water range (say 110F) which would allow the heat pump to contribute even on the coldest day by raising the water from 110F to its max then letting the boiler top it off from there. Since you also have radiant floors, that part of the load load should 100% fall in the range of a heat pump. As the outdoor temp increases, more of the heat will come from the heat pump. It would also handle the AC and part/all of the DHW.

The pairing of the two would let you use a cheaper non-condensing boiler because:

1. The heat pump and boiler could share a buffer tank so the water volume of the CU3A isn’t needed.

2. If the boiler is contributes most during the coldest weather, those are the conditions with the least amount of condensing so the efficiency gains are the smallest.

You might want to consider fan coils as an alternative to or in combination with Runtals. I used Jaga fan coils combined with radiant floors. Currently on a gas boiler but looking to upgrade someday to an air to water heat pump.

My heating design temp in San Francisco is 41F. Easy compared to Boulder. Good luck.

Thanks for the great suggestion piperspace...I looked at radiant panels with fan coils and was possibly planning on using one or more in areas where we have limited wall space for the radiant panels and could use the fans to boost the heat output for a given wall area. Eventually if the tech were to get there we could possibly some day replace the boiler with an Air to Water heat pump....just need to get those temps for here in Boulder, CO. I will take a look at the Jagas.

The point is that you can use an air to water today - the right installer can do it.

amovida123, if you want to see a low-temp/heat-pump, air-to-water install near you, reach out via email ([email protected]). I'm also in Boulder, CO.

Thanks Paul and piperspace...you have me thinking about it. Part of my hesitation in going that route was not necessarily trusting some of the equipment in terms of longevity/servicing mostly because there is not a ton of information or feedback out there for these companies but mostly because I don't know enough about it. I really like the idea of going with proven brands such as Veissmann and Mitsubishi. I had watched some of the John Siegenthaler videos talking about the air to water technology. The contractor I had come out after looking at the house suggested air to air heat pumps instead. I guess in all honestly as the system that needs additional fans (moving parts) in the radiators and we have an older somewhat leaky house that has a design temp of -2 and can occasionally hit -10 or even -15 I was worried that the system would not keep up and was concerned about maintenance. I also believed we would give up cooling...not sure if that is right? If not how does the cooling work? Are air to water heat pumps able to deliver enough BTU's in really cold temps for an older not super well insulated home like ours....we sometimes have fairly long cold snaps? Or that is where the boiler would come in...what type of boiler do people typically use? Some of the heat loads we have are around 8K in a room...can the JAGA's meet that load? Thanks

I had similar concerns about air to water heat pumps even in our mild climate. It felt like a science project back in 2018 when planning our remodel. Now we have one full winter under our belts with the system on gas boiler. I ran it not to exceed 120F for the circulating water and it worked well down to 42F. Now I am optimistic about doing an air to water upgrade someday.

I am using a “combi” gas boiler by Navien. It both heats the house and provides DHW. When installed it had software issues but those were fixed under warranty. Support from Navien was uneven but ultimately OK.

Yes, Jagas can meet an 8K load. Look for tables in the spec sheets showing BTU output based on length of the unit and circulating water temp. The ones I used are called “trench” heaters that are recessed into the floor. So, I put in 3 units to cover our main floor load which I calculated would need 15K BTUH. As it happens I did not need that much heat and I turned one of them off.

The deal in general with heat pumps is they can make heat pretty well even when it’s cold outside. But their efficiency declines as it gets colder. So called “cold climate” products retain efficiency better at lower temps. Those can be cheaper to operate.

I don’t have to worry about AC in SF. We use fog for that. The Jagas do come in hybrid models. Meaning they have a drain pan to catch condensate which then has to be drained away. I also saw a presentation by Siegenthaler where he suggested adding separate air handlers with ducts for AC. Kind of a compromise but maybe OK if your need for AC is modest. I think he was talking about upstate NY.

Veissmann makes air to water I believe. Mitsubishi definitely does, but I don’t believe they’re available in the US. Cooling can come from fan coils - they come in a variety of shapes. Basically the same options that air to air has, air to water also has - ceiling, high wall, low wall, ducted, etc. They zone much better than a multi- split can.

Don’t think in a binary here: a boiler and heat pump can work in tandem. The % just shifts towards boiler as it gets colder. Any boiler works, but it can make sense to go cheaper and less efficient as you will ask less of the boiler.

As to leakiness - it doesn’t matter. A Btu is a Btu, nothing is special about the Btu from a heat pump vs a boiler.

Usually I think air to water is too complex and expensive and air to air ducted is best, but you’re already going the complex and expensive route with viessmann and runtal + multisplit, so it might work out best here.

This is a great resource: https://www.caleffi.com/sites/default/files/media/external-file/Idronics_27_NA_Air-to-water%20heat%20pump%20systems.pdf

piperspace and paul- Thanks for getting me thinking about this again...and being kind enough to educate me.

I took some time today to reconsider and read a bit about air to water heat pumps and enjoyed this very interesting article on GBA about one family’s journey on a retrofit install : https://www.greenbuildingadvisor.com/article/air-to-water-heat-pump-retrofit

I also am beginning to comprehend Paul’s points about the pros of:

1. buffer tank/boiler combo

2. and the benefit of using a smaller less expensive boiler.

3. and that you can pick radiators to match low load rooms

4. And not sure I understood this right but for when the boiler picks up the load (cold temps) you could employ the efficiency of a condensing boiler because you are only getting low return temps…do I have that right?

5. The COP on the air to water look equally impressive as air to air.

I’m also still seeing a number of cons

1. You need to run power to each radiator if you’re going to size them with fans…not an easy task in a lathe and plaster home with lots of wall cavity blocking. The author of the article I referenced above suggested they would only consider employing the radiator units for cooling if they were doing a gut remodel. I think they used non fan coil units only for heating along with in floor heat.

2. The family in the article had existing radiant floors that they were able to tie into…I sadly, do not. If I did then the air to water would be a no brainer. But I would need to put radiators in every space/room minus the small area where we will have in floor radiant…basically one hall and one room.

3. Each of the wall units would need a condensate drain…same problems as with the electrical. There was also some talk about possible problems with condensate along the hydronic supply lines depending on your humidity levels.

4. Not sure how well the cooling would work. I could not find anyone online talking about their experience cooling with an air to water heat pump with fan coils. It looks like John Siegenthaler is recommending separate ducted air handlers for cooling…not sure if this is correct?

5. I could see employing a Jaga unit to test one out but I am not sure I am ready to deploy 9 or 10 of these given the scant information online. Looks like they are primarily employed in Europe. I could not find any reviews…guessing they are out there somewhere.

6. For me I see the same issue with the air to water heat pumps themselves…will these companies be here in 10 years to provide parts and service? Maybe my biggest concern is looking at the equipment and the web sites of these companies it all feels to me a bit of early days. A lot of the web searches I did lead back to the UK where I know they have embraced this technology. The YouTube channel with Urban Plumber has some of the best and most entertaining installs of air to water heat pumps I have ever seen. He works mostly with Valliant but those are not sold in the US. There is even a video where he uses air to water on regular radiators and has a happy customer: https://www.youtube.com/watch?v=2jM_oKWptaI&ab_channel=UrbanPlumbers

7. Also wondering what the turndown ratio would be on some of these units? If you are just calling for heat in one area of your home and you need minimal btu’s will you lose a lot of efficiency. I am hoping that using 6 outdoor air to air units I can achieve very low turndown to supply very low loads. But again, I am out of my element here…so if my thinking is off I welcome being corrected.

With the setup I am thinking about with the Runtal and the air to air heat pumps I have excellent areas to run the refrigerant and hydronic lines without too much complication as a few crucial areas are already open due to our current remodel work.

At this point my thought is to stay with what I see as proven companies with relatively straightforward installs without getting into powered and fanned heating and cooling radiators with early technology. We have moderate insulation and somewhat leaky windows….I am thinking I want to be sure the system we install will make the house quite comfortable…comfort is something I value highly. Some of what I read suggested that R290 could be a game changer in terms of getting up to 180 degree temps so I would keep that in mind during the system design. Maybe we could swap out or boiler in 10 years with an air to water that can deliver the temps when the technology is more proven. I also might change my mind if I could see an air to water house in action in my zone….guess I am not totally decided.

I am going to keep the door open and may give SpacePak or another installer for someone like Enertech or Nordic a call for a quote. In the meantime I think I will repost this question and see if I can get anyone to give me a hand in analyzing what is the best of the air to air heat pumps configurations I have in my attachments.

Glad it was helpful!

A few clarifications:

1. Your current path requires electricity, refrigerant and condensate piping to each of the 6 interior units. The air to water is electricity, condensate and water. So same deal there. You will certainly be drilling into the walls either way to mount 6 units and the Runtal. Likewise, refrigerant lines and water lines both must be insulated if used for cooling or condensation will happen where you don’t want it.

2. You do not have to use the radiators with fans. You can just use the Runtal + wall mounted unit. The difference is that the wall mounted units, which you are installing either way, use water. You might find a way to duct a few rooms, once again, same deal just water vs refrigerant.

3. You could run the heat pump + a condensing boiler. But the point I was making was that the benefit of a condensing boiler is much less, so you can go with a simpler non-condensing boiler. But if you want it, go for it. Condensing boilers fall in an in between efficiency (better than cast iron, much worse than a heat pump) and lackluster reliability that makes their value very tenuous. So subtracting a large chunk of their heating makes it an easy cut.

4. “ But I would need to put radiators in every space/room minus the small area where we will have in floor radiant…basically one hall and one room.” this part doesn’t make sense. In every scenario presented here, the rooms need a heat source. If it’s Runtal, great. If it’s a wall mounted unit, great. If both, great. This should be the same across the board.

5. Turn down: depends on the model. With the buffer tank, it’s less important. An air to air has no buffer so it’s more sensitive. You’d be installing a buffer (the Vitocrossal is a one piece boiler + buffer) either way.

6. Comfort wise, there is no difference between Runtal heated by a boiler vs. a heat pump + boiler.

I think to summarize, the major technical differences are: 1. pumping water vs refrigerant

2. Dealing with mismatched loads via a dual use buffer tank + 1 outdoor unit vs a buffer tank and 1-6 outdoor units.

In terms of unfamiliarity, I think you’re entirely right. Air to water isn’t common here, because hydronic heat is really unpopular. Hopefully the Viessmann guy gets trained on one of these https://www.viessmann-us.com/en/products/heat-pumps.html!!

> I also might change my mind if I could see an air to water house in action in my zone….guess I am not totally decided.

In case you missed it above (I mistakenly replied to Paul's comment, not yours), I have an air to water heat-pump heated and cooled house in Boulder, CO. Happy to give a tour and discuss our experience getting it done. An in-person discussion would be much higher bandwidth than going back and forth in the comments. Contact me at [email protected].

Paul and scisguy- Very appreciative of your responses. Alright the wheels are still turning....albeit a bit slowly after last night's BBQ. ;)

sciguy- Thanks for the generous offer...I'd love to take you up on that and see your home/system. I'll shoot you an email. thnxs!