A hybrid Swedish-ish/Pole Barn-ish Wall Assembly?

I’m working through the wall assembly plans for a Climate Zone 4 home in eastern Tennessee.

NREL has several papers about condensation control in high-R value wall assemblies, often suggesting that up to 50% of the insulation value should be on the exterior of the sheathing in the winters even in CZ4 if interior relative humidity is high enough.

NREL WUFI analysis where every wall fails and we’re all going to die from mold (even the author asks what WUFI is smoking to reach these conclusions):

https://www.nrel.gov/docs/fy13osti/56709.pdf

NREL water content percentages based on exterior/no exterior insulation and indoor relative humidity, including CZ4:

https://www.nrel.gov/docs/fy14osti/60487.pdf

I like the recommendations of the whole wall R assembly recommended by Building Science Corporation and NREL:

Walls: 25

Vented Attic: 60

Unvented Attic: 45

Basement Walls: 15

Subslab/slab edge: 7.5

This was long before COVID, where they believed these to be the most economical numbers, but 2″ of the cheapest foam insulation used to be $28 and is now $40 around here.

So I’m wondering if a wall that takes notes from some Swedish factory built homes:

https://www.youtube.com/watch?v=G0jbevroIEs&t=2530s&ab_channel=GreenBuilderMedia

and from insulated pole barns, for examples:

RR Buildings:

https://www.youtube.com/watch?v=OUYCbQSErAU&t=545s&ab_channel=RRBuildings

Hansen Pole Buildings:

https://www.youtube.com/watch?v=3AP8Pp3hXT0&ab_channel=HansenBuildings

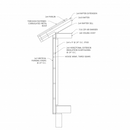

So here’s what I’m thinking, and wondering if it’s an assembly that wouldn’t cause any mold issues. From the inside out:

– Vapor open paint

– 1/2″ drywall

– 2×4 @ 24″ O.C. studs, filled with R-15 Rockwool batts(or R-15 fiberglass)

– 7/16″ ZIP Sheathing (or maybe just regular OSB with seams taped?)

– 2×4 @ 24″ O.C. horizontal scaffolding, filled with R-15 Rockwool batts

– House wrap, seams taped

– 1x vertical furring strips

– Cladding

What I like about this assembly:

– It keeps the sheathing between layers of insulation.

– It’s easier to build than an interior structural wall that’s sheathed and then an exterior insulation double wall, because no one here does dense-packed cellulose.

– It’s a lot cheaper now than exterior rigid insulation board.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

In climate zone 4 as I recall you do not have worry about condensation as we have enough warm weather to allow the walls to dry.

Sorry I tried twice and could not get thru the video but failed. In the US a pole building seem to be a cheap drafty place to keep your tractor dry and they are great for that but when you convert them into a high performance buildings it seems to cost more than to just build a normal building.

When I look at your wall it seems you bought all the lumber to build a double wall but put it to close together and then filled it with bats that will have gaps and seams to leak. If you want /need an R40 wall build your fill it with cellulose.

Seems like a 2x6 wall filled the damp sprayed cellulose with a layer of reclaimed used foam on the outside would get to your R24 goal for fewer dollars.

Walta

I forgot to mention that I have considered a double-stud wall, but there's no one around here who does dense-packed cellulose.

I have seen the pole building videos. I am not sure how the IRC code addresses them. They seem like they would have excessive deflection in wind or seismic events. It seems you would need engineering on the structure to meet code.

How do the insurance companies view them for premiums?

I'm more so considering the pole barn aspect where you have batt insulation behind house wrap without exterior sheathing between the wrap and batt insulation.

So this is something like a Larsen Truss but with batts? Why not rigid rockwool on the outside?

Also reminded me a little of the Tier 2 and Tier 3 in 475's smart enclosures: https://foursevenfive.com/3-tiers-of-the-smart-enclosure/ Both of those are sheathingless (although they both imply rigid exterior insulation).

Right, kind of like a Larsen Truss but with batts, and the exterior truss simplified to a single 2x4. I'm hoping turning it horizontal would help to minimize thermal bridging. I wouldn't mind Rockwool Comfortboard 80 or such on the exterior versus this, but from what I'm able to gather from local insulation companies, rigid Rockwool just seems really hard to come by right now.

There is sheathing in my assembly, it's just in the middle instead of on the outside. 475 assemblies without sheathing have been tested (again by NREL, maybe BSC too), and they're easily a 1/4 as strong as walls with sheathing.

Cool. FWIW I've done 24 horizontally to hold rockwool batts (mine was internal but no difference). I used a pocket screw setup to attach them, but that was in part because I was furring down rafters (and it was a small area). I guess you'd just cut spacer blocks (width of the rockwool) and rest the next 2x4 on top of those. Then you could toe nail them to the vertical rafters? Or perhaps a few long screws all the way through? Or maybe toe screw with a self-drilling screw?

Hi,

So the assembly seems to be metal siding, 2x4 horz girts with rockwool infill-screwed with narrow face to the wall so 3.5" deep, WRB, sheathing, vertical 2x6 wall studs& insulation between the 2x6 studs?

Your proposed wall should have excellent performance in your climate. The horizontal cross strapping gets you most of the benefits of continuous insulation without the cost and hassle of dealing with rigid mineral wool boards. Make sure to tape or liquid flash the seams of the sheathing on the 2x6 walls as it should be your main air barrier. Taping the seams on the house wrap doesn't hurt but also not needed.

Without sheathing on the outside, I would watch your critter barrier. Depending on how persistent local wild life is, you want to make sure your critter barrier is continuous across all cross sections otherwise you'll be building a very comfortable nest for them.

The roof details look complicated. If you are using your ceiling joists as rafter ties, they need to be nailed to the side of the rafters, as sketched will only work with a structural ridge beam. Usually the simplest is to have the ceiling drywall (or vapor barrier above it) as your ceiling air barrier. You can connect this to the sheathing air barrier with a wide piece of flashing tape that is installed on the walls before any rafters go on. The cc SPF is not really doing much, not sure if needed at all. Insulation baffles to keep the cellulose in place and the vent gap free is all that is need there.

The roof detail comes from the idea that I'd like a really safe space to work on the rafter framing. I don't want to walk from ceiling joist to ceiling joist. It also lets me more easily use the ceiling joist rim board as window and door headers.

Having the rafters over the ceiling joists is a detail I've seen on Building America Solution Center (a government site for building science):

https://basc.pnnl.gov/resource-guides/attic-eave-minimum-insulation#edit-group-description

https://basc.pnnl.gov/sites/default/files/images/TE-41_atticeaveinsul2_sthfc_01-01-11.jpg

And Fine Homebuilding:

https://www.finehomebuilding.com/app/uploads/cms/uploadedimages/images/homebuilding/qa/hb140QA01-01_lg.jpg

so I'm just planning to drive Simpson structural screws from the ceiling joist rim board into the rafters above. Those handy little 4.5" and 6" screws are going all over the place. It's a detail that'll cost more, but I think the safety it'll provide is well worth the expense.

I would run your idea by a structural engineer, my guess you need a bit more than screws there. Depending on your roof loads, you probably need some Simpson hardware to handle the outward rafter thrust.

If you are putting plywood over the ceiling, might as well build it in away to be usable storage if need. You can build your ceiling joists with tall I-joists or trusses that would have enough space for insulation under the the plywood. As long as you leave enough of the plywood unsecured, you can loose fill the whole thing after from the attic.

CC,

I think it will work well. The only thing I'm not sure of is whether there is enough of a difference in the thermal bridging to make it worthwhile to run the exterior 2"x4's horizontally (with the complications and extra work that brings), and just building another conventional 2"x4" wall and offsetting the studs.

Malcolm,

After modeling both and checking the cross section of intersecting stud points, I think you're right that it won't matter whether they're vertical and offset, or just horizontal.

CC,

One other small suggestion is to bring your foundation out so both walls can sit on it, while still allowing the outer one to run down past the floor framing.