2×8 cathedral ceiling insulation – Climate Zone 6b

I’m in the middle of a project in a 6a zone where the previous builder has walked out and I am trying to determine the best approach to achieve minimum code for insulation on a 2×8 roof with a cathedral ceiling that has a bay window with ridges.

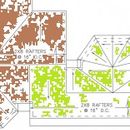

In the attached image the brown represents the existing house and the green represents the addition. The old roof is vented — and attaches to the new addition.

Is foaming 7.25″ of closed cell insulation the best approach to the addition or should we be considering other alternatives?

I am concerned about the thermal bridging by using foam for the entire cavity and attaching one end of a vented roof to an unvented roof.

Any help is appreciated!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

>"Is foaming 7.25″ of closed cell insulation the best approach to the addition or should we be considering other alternatives?"

You should be considering alternatives.

Closed cell foam is the opposite of "green", even when blown with HFO blowing agents, and when thermally bridged by framing a large fraction of it's potential performance is being robbed. See:

https://materialspalette.org/wp-content/uploads/2018/08/CSMP-Insulation_090919-01.png

...and...

https://www.finehomebuilding.com/2017/07/10/closed-cell-foam-studs-waste

So really anything more than the minimum necessary for adequate dew point control (with the remainder being cheaper-greener fiber) would be a waste. In a zone 6 roof it only takes about 50% of the total-R to be closed cell foam to have adequate dew point control at the foam/fiber boundary.

Assuming the roofing is already up , the opportunity for using rigid foam on the exterior has passed. Installing 4" of HFO blown 2lb polyurethane would deliver about R27-R28, leaving 3.25" of depth for other insulation. Installing 2.75" deep "Bonfiglioli strip" insulating furring on the rafter edges with 1.5" wide strips 2" foam held in place with 1x furring increases the cavity to 6", which would deliver an additional R22 if filled with cellulose. See:

https://www.finehomebuilding.com/2014/11/26/breaking-the-thermal-bridge

Backing off to 1.5" on the foam would add 2.25" to the depth for only 5.5" of rafter depth, which would be sufficient for R21 fiberglass (HD batts or 1.8lb dense-packed blown) or R23 rock wool.

The thermal break provided by the foam in the rafter edge strips means you might be able to hit code compliance on a U-factor basis (rather than R-value) with just 1" foam strips. But it could be close, depending on the actual framing fraction of the roof design, and it would have to be calculated, whereas it's dead-easy to make code on an R-value basis with either of the insulating edge strip approaches above.