Calling all “rammed earth” experts…

I was recently thinking about “rammed earth” construction.

I found an episode of “The nature of things” where David Suzuki talks with a rammed earth builder that calls his approach “SIREWall”

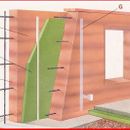

The main innovations with “SIREWall” seem to be the inclusion of rigid foam insulation in a manner that appears similar to a Thermomass foundation and higher compressive strength than more traditional rammed earth techniques.

The performance/durability advantages as I seem them are:

Rammed earth is “airtight”.

There is no “interstitial” space – ie: no 3D network.

There is (possibly continuous?) R value.

There is built in thermal mass for decrement delay.

The earth may be hygroscopic (moisture buffering) but not sensitive to moisture damage.

The walls may be very long lasting.

But what about disadvantages?

SIREWall is apparently a proprietary technique, ie: specific details are behind a paywall.

Can the wall be engineered so that the insulation is continous throughout or are there (ie: top of wall) significant thermal bridges?

Thermomass foundations use fibreglass ties to connect the concrete through the rigid foam but I don’t see anything like that in the details at the SIREWall site…

Traditional rammed earth can be quite “buildable”, but I wonder if this is still the case when you try to do something like “SIREWall”…

How does one normally install wiring and plumbing in a rammed earth wall?

Just wondering…

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I am not an expert by any means, but I do have some Rammed Earth experience. I do not believe what Sirewall does is that unique, and I doubt that it is that proprietary. The first builder I worked for is now an exclusive Rammed Earth builder in B.C. who learned some things from Sirewall. It is buildable, labor intensive, and in my mind the most beautiful wall. Sirewalls higher compressive strength is called Portland Cement.

Matthew,

Thanks for sharing your experience.

I know that rammed earth construction has been around for a long time but I have never seen a system besides "SIREWall" that includes rigid foam on the inside of the wall.

What I'd like to know is:

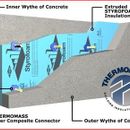

Why is it that the two "Wythes" of rammed earth don't seem to have to be connected to each other through the foam like a Thermomass foundation?

Is the insulation continuous?

What are the usual techniques for installing wiring and plumbing in these walls?

What are other disadvantages to this type of wall system?

Lucas,

My only experience with rammed earth was staying in my wife's cousin's Earthship (http://earthship.com/) in Santa Fe. The basic system there, as you probably know, was used tires filled with rammed earth, covered with metal lathe and plaster. The texture of the walls was exquisite; the performance of the house was miserable. I could imagine that with exterior foam and better, sun-shaded glass it would have been more comfortable.

I can't see the logic of building double earth walls with foam in the middle. There must be some logic to it or they would not have been in business so long.

Michael,

I have always really liked earthships for their "buildability", their aethetics and (when built in one of the handful of appropriate climates) their durability/performance.

What made me lose interest was that I had never seen a rammed earth structure that was also insulated in a practical way (ie: a rammed earth structure for colder climates) - until I saw this "SIREWall" approach.

I'm a curious person and now I want to know more - but I am not flying out to the west coast to take a course.

To start: I have worked as an insulated rammed earth builder for 10 years as well as working for the founder of the above mentioned S***Wall.

It is important to establish that putting insulation between 2 masonry walls is not revolutionary, it has been done for a long time. Not possible to claim ownership of that. You can not patent that idea but you can patent forming systems or certain sequences of construction methods...which they have done. Most people are impressed by the word patent and don't bother to investigate....smoke and mirrors. To answer your question, franchising and the costs and other associated shenanigans are some of the disadvantages.

Yes, continuous insulation is possible.

We run our electrical through thick plastic conduit and have a steel or heavy duty plastic electrical box that can withstand compaction. The conduit runs to the top of the wall.

There are hundreds of pics on my site (http://rammedearth.info/) if you want to learn more.

C Schooley,

Thanks a lot for all the photos.

Some really interesting stuff on your website.

I'm still scratching my head over the engineering similarities with Thermomass...

So you don't use any kind of connectors like a Thermomass wall?

Have you ever built a non "stabilized" wall with continuous rigid foam insulation through the centre?

What is the coldest climate you have ever built an insulated rammed earth house in?

Are you based on Saltspring?

A friend of mine has a place near Mt. Maxwell and I've had some good times there.

Clifton Schooley, thanks for posting the link to your website. You have very nice work. Rammed earth is really a beautiful material.

For those who are inclined to push the R-values higher, I would guess the foam layer could be thicker, and if the walls are already two feet thick it shouldn't hurt to add a couple more inches.

Beautiful work, Clifton!

i really struggle w/ whether this system is rammed earth or not. i'm familiar w/ the process and have had various discussions w/ people who took their training. to me, it seems like it's really rammed concrete that is heavily tinted.

Mike,

I know what you mean.

It would be interesting to know if something similar to "SIREWall", or whatever, has been done without "stabilizing" the earth with cement...

I don't know if you are aware of a rammed earth home built in southern Ontario it uses a similar technique. If you google "Ontarios first rammed earth house" you will find some pictures and information. My wife and I were looking at the possiblity of constructing a rammed earth home we have now settled on a rammed earth shed for starters.

Some things you might want to know:

SIREwall is a trademark which is a descriptive for Inulated Stabilized Rammed Earth (ISRE).

SIREwall builders work under a franchizing agreement.

The proprietory business and the Patentdirectionare both efforts to claimownership of rammed earth (RE) building techniques that include the process, the forming for RE, the placing of insulation in the middle of the wall, etc.These methods and procedures existed in masonry, concrete and rammed earth construction prior to any proprietory claims.Clifton's points on the proprietory issue ring true except that the Patent for selective aspects of the forming technique (to the best of my knowledge)does not currently exist, athough there is an attempt to aquire such a patent in a number of jurisdictions.

Approximately 12 Independent professional builders paid for training by the SIREwall organization prior to the existence of the franchizing business model. Some of the other independent builders who work in the Re field were also trained by the SIREwall organization. The independents have built numerous residential and commercial RE projects in the USA and Canada in the past several years.

Stabilization is generally required where earthquake conditions exist, when buildings exceed a single storey and when other structural and load bearing elements of the building are supported by the RE walls.

Stabilization of Re is achieved with the use of small amounts of Portland cement (6-10%) and the installation of reinforcing steel (rebar) oriented both vertiacally and horizontally in the wall(s). The two wythes (walls) sandwiching the insulation core are typically connected with reinforcing steel in a configuration established by the structural engineer & related to the building design. Some options are: either open or closed stirrups placed horizontally, spanning the insulation and capturing vertical rebar in both wythes; diagonally placed rebar, vertiacally placed, spanning the insulation and capturing horizontal rebar at two different elevations in the opposing wythes. Engineers will typically use either the masonry or the concrete codes to designRE walls unless code for RE has been developed in the region.

Insulation in the walls ifs often the rigid foam type. Compressed mineral fibre batts, up to 5" thick and designed for masonry construction, have also been used successfully. A brand with a large mineral recycled content, hydrophobic characteristics, resistance to rodents and other pests, and LEEDS certified has been successfully used in ISRE walls.

A reduction of thermal bridging is desitred and achievable. The degree to which it is achierved is generally governed by engineering considerations.

Building ISRE in hot or cold cliimates requires more rigorous attention to the weather conditions than when building with masonry or concrete. Since RE material has both a very low moisture content (is essentially a dry mix) and a low Portland cement content, curing conditions become more important than for masonry or concrete work. Protecting the raw materails, soil mix and walls from excess heat, cold, rain and snow while in storage and during the construction and curing phases is essential.

The question of whether Modern RE is rammed earth or not is an open one. Keys to comming to your own decision on this are cause for reflection.

In it's ancient, historical sense RE is basically a high clay content material which results in successful wall construction the stickier the clay is. Typically protecting these walls with a lime plaster has helped to increase their longevity. These walls are rarely structural but act more as barriers to the elements. They are often wrapped around, or placedd between the structural masonry or timber frame elements of a bulding. Due to lack of stabilization these walls need continuous care and building them outside of certain geographic and climactic regions is limited.

Mordern RE on the other hand can be built wherever appropriate material can be found. It is a more technically based material but it is a pure materail in that the soil / aggregate does not need to be washed free of clays and silt. Blending of soil aggragates to provide a low clay content mix is usefull and makes it possible to incorporate a low Portland cement content. Lastly, in comparison to masonry or concrete, very little water is used in the prepartation of the final RE mixture. Teh ramming of the soil, water and Portland cement is the key to achieving the initial stabilization of modern RE walls.

In closing, the colour of your soil can dictate the colour of your walls. Iron oxide additions to create a different easthetic is common in modern RE.

BUT - Modern RE is not just a pretty materail Modern RE has many useful attributes as we look for more natural, planet friendly and healthier ways to develope the built environment.

For more information check out my website (www.ecosolrammedearth.ca) (another work in progress) and the work of the builders members of the non-profit North Americam Rammed Earth Builders Association at (www.NAREBA.org)

Beautiful

Less of a worry to me verses straw walls.

Lots of work playing with dirt. Would love to have done so when I was 18. Might still enjoy it though.

Very artistic, natural... nice

Hi All,

A couple of other points.

I was on site, testing a new version of the Proprietory formwork when the David Suzuki "The Nature of Things" episode was being filmed - right there in the background.

Hey I'm over sixty, so really health and state of mind are all that count if you want to build RE.

the addition of iron oxides is more typical of north american RE. the projects i visited in DE/AT didn't use any. the RE house we worked on didn't use any. frankly, on most projects it's overdone and fussy.

also, i have some serious qualms about whether there is really a reduction in the amount of portland cement used. fo example, if switching from a 6" conc. wall @ 6 sacks portland cement per cubic yard to a 12+" RE wall @4 sacks portland cement per cubic yard, there is no reduction (in fact the opposite)...

as long as said patent doesn't include batch mixers and concrete forms that have been available to RE builders for a while...

Arno,

Thanks for replying in such generous detail.

10% +/- portland cement stabilization is mostly for compression purposes, and the rebar for tensile purposes. It can be done without either, but in a country full of liability laws, no one could ever do that, unless they are without codes.

Hello Lucas,

Thank you for your interest in the SIREWALL System. SIREWALL has spent close to 2 million dollars on the research and development of our continually evolving system. The WIPO has stated that all 84 of our claims are unique and patentable. (I apologize, for not supplying links but I cannot seem to do that in this format).

As I understand it your requests were for thermal detailing, electrical, and comparing to THERMOMASS.

THERMAL DETAILING

I am not sure how to incorporate documents into this message, but would be happy to show you how we keep continual thermal envelope at window, door, roofing connections, etc. Please contact me off our website (www.sirewall.com) and I will provide this information.

In David Easton's book he mentions concrete bond beams, to tie the walls together, at the top. The SIREWALL System has been engineered for the same Seismic zone as San Francisco and is held at the bottom with wide footings allowing the wall to act as a vertical cantilever. Each wall is individually supported. We do not use bondbeams as they would create a huge thermal bridge (ie. the equivalent of putting a single glazed window around your whole building...). We use steel or fiberglass rebar depending on the application (and the client). We have also done analysis into the impact of the thermal bridging when steel is used.

ELECTRICAL:

We provide steel conduits within the interior and exterior wall cavities. When our wall is complete the electrician arrives, runs his/her wires from the electrical panel, fishes them down the conduit, and attaches them to the embedded electrical box.

THERMOMASS

This product understands (agrees with SIREWALL) on the ideal wall composition for performance. It is a similar wall system. The largest difference, from my limited understanding of THERMOMASS, is that they provide the mass on either side of the insulation, which means that you still need to provide a finish to both the interior and exterior faces. This consequently will result in maintenance requirements. What SIREWALL provides is a " complete wall system". When we leave the wall is complete (with no finishing required). All the components of our mix are integral (including our "SIREWALL Base Admixture" that we developed with a chemist). This allows us to eliminate efflorescence, prevents freeze thaw, and acts as our waterproofing (hydrophobic). Having these components integral means little to no maintenance down the road, and has had one of our Engineers state "there is no reason to suspect that these homes won't be standing in 1000 years".

If you have any questions regarding our System, detailing, etc. please don't hesitate to ask.

Thanks again for your interest! Please let me know if I missed anything.

Cheers!

~ Joss

SIREWALL Project Manager

SIREWALL Operations Manager

Joss,

Thanks very much for all of the information.

This has turned out to be quite a productive fishing expedition.

I appreciate the detail you provided on avoiding the use of a "bond beam".

Where seismic concerns are not an issue, has the SIREWall approach ever been used without "stabilizing" the earth with cement?

Or does Matthew's point about liability apply in general?

I agree with Matthew's response above. SIREWALL has never built without cement stabilization, and it is not currently practically in nearly all first world communities. We use 6-10% cement and gaurantee 10 MPa anywhere in the world. In North America we have been achieving between 25-42.5 MPa over the past 4 years with that same cement content. We are continually doing R&D tests on soil analysis, pozzolans, and other admixtures. The result has been a continual decrease in the % cement to compressive strength relationship. This is allowing us to reduce the amount of cement we require on projects, and we will continue to work towards this until we have eliminated cement all together.

~ Joss

I'm late to this discussion but anyone who's interested in stabilizing rammed earth w/ out Portland may want to check-out Gypsum-Lime Stabilized Earth. Much work / research has been done in Turkey on it but no where else really. The biggest drawback seems to be the set-up time - apparently 15-20 mins after it's mixed. The plus being no Portland.

A few questions arise from reading this topic as someone with no knowldege at all ofnthis construction technique.

1- what exactly is the advantage of this rammed earth vs regular or modified concrete ??

2- as far as looks, could achieve exact same look much easier with panelized system??

It does have an earthy feeling to it, but the labor involved makes me womnder, one could probably order stone slabs from china/ brazil/ turkey with similar feeling, heck i can get some earth color granite slabs for less than 4$ sq meter...

3- any study on its thermal resistance been done ?? It would seem to me it is similar to regular concrete, thus near 0

4- i read " as 3rd world has been doing....". Euh. What ??

Would like someone to point out the positives of this wall method please !!

Jin,

Many advantages of rammed earth construction are in the original post:

The practical advantages of rammed earth over concrete (as I see it) have to do with CO2 footprint and "buildability".

Rammed earth by itself has little thermal resistance but, like concrete, is a thermal mass.

The SIREWall system incorporates rigid foam insulation for thermal resistance.

Rammed earth construction can work well in a "third world" setting because it doesn't require much in terms of specialized equipment or raw materials - it can be a very "buildable" system, using locally available resources like earth and old tires.

Brian,

Thanks for the contribution.

Lucas : airtight, no interstitial space, r value ??it has no r value ..maybe reffering to complete system, termal mass and long lasting ..

these are traits, no advantage here.

Concrete has all the same here, and some other construction methods have similar or better.

( cie insulation value )

I completely understand about the Co2 and energy footprint, though this diminishes as someone pointed out, as soon as you start adding cement to it.

24" walls @ 10% ciment content ( i personally wouldn't go under that unless someone as alternative "glue" substitute is added in the lot..maybe natural latex addmixture? ) equals approximately the same cement content as a 4-6" concrete wall

Then the Co2 argument falls to the ground ..

i understand that it is easier built in 3rd world and or poor countries and that it has been so for centuries, what i don't like is someone using this as a "promotive" trait of the system.

They do it as so because nothing else is available, not so in north america and europa.

Low cement concrete is also easily done using locally available ressources

( aka rocks and sand )

Thermal mass is only good for delaying, and this might help comfort and lower thermo settings 0.5-1celcius..but at the end, total insulation ( and leaks of course ) is the energydrivin factor.

( I know about that , i've got a million + lbs house :p )

So back to learning about rammed earth,

other than aesthetics and "debatable" Co2 footprint,

what are the advantages ??

it sure looks very nice if well done! ( see alot of pictures by now on google image search! )

Jin,

You may be a "shoot first and ask questions later" kind of person...

And it seems like rammed earth building is not to your taste...

Nevertheless, the advantages that have been listed so far are indeed advantages - regardless of whether you want to call them "traits" or something else.

I'm not sure why.

Traditional rammed earth is very low carbon, can sequester junk and be built using recycled materials.

This is a "green building" forum after all and rammed earth is pretty "green".

LUCAS : first off, i have nothing again't any building techniques ( it has done nothing to harm me..yet :p ) and i am sorry if i might have sounded that way in my post..not my point

Then, how greener than concrete is it if it uses the same amount of cement powder ??

If there is no additives used in this type of construction, or another greener than portland cement,

then ok ur right about green product ! but it was mentionned on all sites i've looked into as of yet

and in this dicussion that cement is added for structural benefits.

Then it gets no greener than concrete, and seems rather complicated to get the same strength.

I understand that traditional rammed earth is green of course, using directly take from ground locally available products can't usually be beaten.

Building a log cabin is pretty green in terms of material used and might be the "feeling" one is looking for, but it certainly is far from optimal energy wise if used for a house.

Looked a few videos on youtube,

the walls are built in forms and "hammered" down with power tools to get desired compression ?

What is the final compression strength of those walls ?

Seen a few very large houses in the pictures, 2 story high etc ++

Again, advantages = compared to something else

ICF forms are insulated at R16+, but this is no advantage as it is pretty easy to

get a timber wall up to R16 also.

And solid inner walls doesn't make it easy to run wires etc ..

future modifications also are affected by this.

Jin,

I am not an expert in, or advocate of, rammed earth building.

But I am curious about it.

My interest is mainly in the more traditional approaches - sans cement.

I am not convinced that a more traditional rammed earth enclosure must perform worse (in terms of energy performance) than other types of enclosures.

I'm not sure what point it is you are trying to make about "advantages = compared to something else"...

Have you ever tried to stick frame a house that achieves a Passivhaus level of airtightness while avoiding the other associated design pitfalls that can contribute to unsatisfactory results?

It can be complicated.

A wall system that sidesteps many of those pitfalls because of its very nature has an advantage over other systems that do not.

ICF construction shares many of the same advantages (and disadvantages) of rammed earth construction, as builders of ICF homes are often heard to say.

Lucas : we share the same goal .. knowledge.

I often find that by questioning the reason(s) behind something, its values are usually shown.

If walls of a said rammed earth building are continuous, then yes it will share similar air sealing attributes with many concrete formed techniques, but as i've seen from many pictures,

the walls are often only partials of the building .. this introduces a much more complexe detailing.

I have not done many stick framed constructions yet, but i already understand that trying

to detail something with many assembled parts is best done on a flat plane,

here it is the exterior plane, and i also already understand that insulation doesn't have place inside assembled structures of any kind .

That being said, i agree that by using unrefined materials locally available to make any structures,

you are building green in material section, i still would like to know about the strength of those walls

and how they would resist erosion and earthquakes.

Also, without adhesives, the tension strength must be very low, much lower than the already inexistent concrete one .. how does one build a complex structure that can be approved by local engineers/code ??

If we take the pictures from the original post, when using insulation in the middle of 2 walls,

what is the goal of the very thick exterior wall ? it could've been simply a panel as it is only used for aesthetics then ???

Personally i don't see any point in using this walling method if no insulation is used,

same as having a concrete block house, only looks much better ( and takes probably 20 times longer to build )

And if one is to use 2 walls separated with insulation in between, it has to be for the looks nah ?

In cold climate, i don't believe that all interior insulation would be very wise, unless u find a way to seal 100% vapor toward the earth walls, which will be pretty damn cold during winter time.

So back to 2 walls separated with insulation, how does one make this strong enough to hold roof + snow loads, and or 2nd story ?? will required adhesives in the mix for sure, no smart engineer will allow otherwise .. back to same green specs as concrete.

Still haven't find any compressions strength numbers ..anyone dare to advance something ?

I'd say that this material has a very week integrity against centralized loads..as it will move out the grains and break the tension between layers ... so loads need to sit on very sturdy large plates

to be distributed on enough surface for it not to break the thing.

I trust concrete because it has a relatively high compression strength, easy to manage loads,

45 degree load distribution and we know how it behave with steel rebars in beams.

What kind of tensile reinforcements are used in this material ? how does steel hold up

in contact with the different soil materials and the moisture in the walls ?

( if rebars are used )

Miss Kathy,

Better late to the party than never.

Thanks for the contribution and the resources.

My pleasure, Lucas, I like to think I'm fashionably late.

Jin Kazama, I think you need to tell us more about your million+ pound house!

One difference (trait, improvement, advantage, aspect? I let you decide) is that it's not necessary to use continuous formwork as I assume would be used if one simply poured their house out of concrete or that crazy kooky wacky cast earth.

http://www.castearth.com/Pages/SaltRiverPima.html

At least the cast earth is gorgeous, who here is minimalist enough to live among walls that are coloured with 10 - 15% grey portland cement? That is pretty austere.

I've never seen a concrete formwork blow out in the middle of an expensive pour, but I have seen the terror in mens' eyes as they've told me of enduring such events. Have yet to hear a similar story about ramming a wall.

Also, rammed earth made with 10% cement is basically rammed concrete, it might be time to admit that.

In remote areas where formwork is limited, it is possible to ram in sections to make long walls, as seen here in what might be the longest contemporary rammed earth wall in the world:

http://rammedearth.blogspot.ca/2008/10/worlds-longest-contemporary-rammed.html

(Please note that this was hand-rammed by women who breastfed their babies during breaks.)

Yes, rammed earth is more labour intensive, but I think the human scale is part of the appeal.

Miss Kathy,

I agree.

In my opinion, the "human scale" is not only appealing, but is something important that many cultures seem to have lost in many different domains.

In terms of design and construction, I often equate human scale with "buildability".

There's something to be said for an enclosure design or approach to building that can be executed by unskilled hands.

Popular wisdom usually holds that "more labour intensive" means "uneconomical" - but economics isn't everything and I think it's past time to start questioning that rationale.

I'm late to the party but for the sake of future search engines I'll chime in, though my experience is limited to the design and construction of my own rammed earth home in snowy Canada, where I live.

First off, accept that there really is no such thing as green construction. All construction is destruction of the environment.

Using cement to stablize rammed earth walls won't be the only black mark on your eco-soul. Have you seen what goes into making polyisocyanurate or rock wool insulation? Re-bar? Hydraulic fluid?

Forget the trifling amount of cement *in* a rammed earth wall, think about how much cement is going into the concrete footing *under* your rammed earth wall. That should make you shudder, especially if you are in Seismic Zone 3 or higher.

The walls of my home use a real true 6% cement, I know because I was the one opening the bags. At last test the walls were at 19 mPa which is more than strong enough for me and my engineer. It is not unknown for builders to use a higher percentage during construction to account for hungover crew members or the almighty Liability while crowing about how little cement was used.

Rammed earth wall construction without the use of cement stabilization is not going to happen in North America any time soon on account of all-terrifying Liability. Anything's possible in construction, but mass amounts of soil testing is a great way to dissolve your budget. Randy Bachman didn't have that kind of scratch, do you?

That said there has been some work done with clay stabilizers at MIT:

http://web.mit.edu/masonry/Rammed/index.html

Here are some 2011 photos of that project where you can see that wall finish isn't going to win any awards:

http://www.flickr.com/photos/rammedearth/sets/72157629975390289/

Even still, it wasn't long until Harvard wanted to get in on the act, resulting in this project with Martin Rauch:

http://www.gsd.harvard.edu/#/projects/mudworks-exhibition.html

Mr Rauch has been involved in the construction of numerous cement-free rammed earth dwellings in Germany and Austria, though none of them appear to use insulation in the Canadian style.

http://www.lehmtonerde.at/en/martin-rauch/

A rammed earth wall can be engineered without significant thermal bridging. In my house the wythes are connected with steel Z-shaped tie bars that are stuck through modest (2"-3") holes cut in the recycled foam insulation. Here is a drawing to help you visualize:

http://1.bp.blogspot.com/-hU6HqK1kFbg/UUkZ37YB-UI/AAAAAAAACCg/isGobo-RZV0/s1600/rammedearthwallsection.jpg

It could be possible to connect the wythes using one of these plastic ICF/Thermomass-style connectors, it's all a matter of engineering. As Arno mentions, there are a variety of solutions. Almost as many as there are operators to sell them, I would add.

The "logic" to the double wythe insulated wall, Mr Michael Manes, is that it is cold in Canada, even the warmer parts, and our homes are built with this in mind. C'est la loi.

As Clifton states, there's nothing patentable about putting insulation in the middle of a rammed earth wall, it's something you can do, without permission, if your needs require it. Here's a nice drawing on the subject from Owen A. Rose:

http://www.ecosensual.net/drm/portfolio/Balancing%20the%20Humours%204%20dec%2003.pdf

As far as proprietary admixtures, I found that Xypex (also developed by chemists) worked quite well on my project to eliminate efflorescence, prevent freeze thaw, and act as waterproofing without the headaches associated with Joss' company.

This lovely home was sealed with a natural product called Broda to the satisfaction of Canadian permitting officials:

http://rammedearthsolarhome.ca/

In Australia you can use Crommelin Rammed Earth Sealer.

Unfortunately, it looks like Ramseal is on hiatus as of early 2013, but they're worth contacting to get a more experienced perspective on the topic.

A simple image search of the terms "rammed earth" should give anyone with aesthetic concerns plenty of food for thought, as this technique can be expressive in ways poured concrete cannot.

Jin Kazama, seek out a book titled "Buildings of Earth and Straw" by Bruce King to find answers to your structural concerns.

I'd like to clarify that "earthships" and "rammed earth" are two very different systems. Earthships use tires filled with compacted soil, then covered with stucco or plaster. Rammed earth is a moist soil mix compacted between formwork. The former is much, much lumpier than the latter.

For more information on the latter check out my blog:

http://rammedearth.blogspot.ca/

cheers,

Kathy

REi4E