Retaining heat at a garage door; part 2.a.07x

Fairbanks, AK, zone 8. This is an iteration of a design I asked about last year; different foundation system, somewhat different ramp. I looked for that thread to see exactly what was said, but could not find it, so I apologize if old ground is being dug up again.

I am still struggling with getting some kind of heat retention at a garage door, a desire that may be nearly pointless given that garage doors notoriously leak. (That said, I was sitting inside my neighbor’s the other day at 20 below, and could not detect any leakage by hand, fwiw. 2 story, non-super-tight house.)

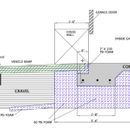

Picture one shows a cross section of the proposed foundation and slab in the middle of the garage door. My idea is to build a wooden ramp (2 per vehicle) into the garage and have some measure of thermal break at the slab. Picture 2 is a top view. There will be radon, StegoWrap, gravel, etc, so those issues are not of concern right now. The concerns are this: (1) Is it even worth dinking around getting a thermal break between the ramps and the slab? (2) Are there obvious improvements to this?

BTW: I’ve looked at the psi on the foam under the ramps that a one-ton pickup will generate, and at 30 I think 100 psi XPS will not creep…. for a while. The whole house will have the same foam/stem wall setup, sans the notch for the ramps.

There are obvious alternatives, including running the concrete out farther and having less psi on the foam from the truck, etc, etc.

As always, any comments or suggestions are surely welcome.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

John,

The wooden ramp will be expensive. How durable will it be? Will it get dislodged by your snow plow?

Otherwise, from a thermal perspective, the detail looks good.

Martin,

I hope this thread is not too old to get some replies. Hello, hello, is there anybody out there? Just nod if you can hear me...

John, it looks like you're using 2 wooden tracks as a ramp to drive into the garage. That's a helpful low-cost idea. I'm wondering if you've built this and whether the wooden tracks/ramps have been subject to noticeable frost heave?

I am definitely somewhat confused about insulated slab foundations, especially where they meet doorways and other exterior access like a garage (I'm designing a heated garage space).

I realize moisture should hopefully drain through the gravel section at the ramps in the drawings above, but isn't horizontal sloped insulation below the gravel likely to prevent thermal heat energy from conducting through the gravel area and won't the gravel actually be kept closer to air temperature than to below frost depth temperature?

I'm looking at ways to bring a concrete ramp up to a 16" raised insulated slab from grade. It would be great to do everything in one pour, but there is no way to really keep the exposed surface of a driveway like that from conducting cold temperatures downward and allowing possibility of frost heaving.

Am I misunderstanding the importance of a heated air space above exposed concrete? I suppose if a concrete ramp is poured after the house foundation, you could run vertical eps or xps insulation to depths below frost depth, and include horizontal insulation at that point.

Seems you'd lose the point of an insulated slab because now you're back to lots of excavation in that case.

Anyone have insight about this?

I am here. After looking for details quickly I decided to come up with my own. Mine is in process of building, so I will let you know if I like it and have another house I am doing in a few months that will let me try again and may do something different if I feel an iteration is in order.My details are for a frost protected shallow foundation with heated garage and ICF walls. It also accounts for the man-doors and how the concrete forming is built and poured. I do the same sort of offset feature for the man-door as the main bay doors, but instead of a cellular PVC deck board it is sized for an inset threshold. (I prefer roll in thresholds so everything is ADA compliant.) The fiberglass keeps them on the same level and to avoid drift, but maintains the thermal break and corrosion resistance. One picture is how I built the forms and the other is the final install detail. They are not in total proportion one to another as I had to do some design changes but don't have a lot to time to dedicate to fleshing it out right now. I would recommend a 2x8 size (rather than 2x6) to get the apron thickness to 5 inches thick for the first portion near the junction and then use standard 4" after that. The eps wing outside can be extended to a full heated driveway or just the minimal distance to comply with FPSF code. I will also try to take some pictures of the actual form I have set up before they pour and post the phase pictures after it is fully installed.

John, Since you welcome all suggestions....

Why not Build a Garage Just Like Thorsten Chlupp's?

Equal Door in Canada makes a pretty good insulated door for not too much

How about an old fashioned concrete skirt and having the foam come right up through the surface under the door[edit] rather than in front of it as shown] say 3 1/2 inches wide covered by a piece of PT. I did this with 2" of foam in my last garage. TIres never really touch the foam

Martin: Thanks. Those are all valid concerns, the answers to which are TBA.

J Brooks: I have looked at two of TC's garages, and I did not see anything in particular there. I will be asking him about this specifically soon, as I plan on another quick consult w/ him.

Keith: I had the foam under the door, but figured it would get a little smooshed be the tires and leave a gap, so I moved it. I thought of extending the plywood over the foam, as I'll do to the side of the ramps, but would have to have two layers, I think. Easy to do.

Thanks all for the opinions.

you might consider looking at commercial garage doors. I found some that are used on large refrigerated warehouses that are designed to seal well and can be ordered with up to 6 inches of polyurethane insulation. Comes in all the colors you want....as long as it is white! The company I can recall is Kingspan

Kevin: Unfortunately, commercial doors here (at the two places that "do doors") are only slightly different than residential doors. Same R value (2" and R17.... I wonder if they are including a hypothetical 4" of dead air on each side....), but heavier hardware. That is the best they do, apparently. Good idea, though. Thanks.

John, the plan is not for me. Knife edge of foam brought near the surface would do what you are looking for. Concrete apron, no PT. Add radiant heat too.

One older thread;

https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/19854/slab-garage-door-how-insulate-hold-back-pex

AJ: Thanks for the link; that is the thread I wanted to review. I got the idea of using wood instead of concrete from Martin's comment there. Wood has a better R, but a higher PITA factor, too. I'll think about the knife edge, but I don't see exactly how to do it w/out running the concrete out farther, leaving more concrete exposed. I'll look at it. Yes, there will be radiant in the floor, starting 4' from the doors.

John K, I didn't know that Thorsten had a garage....

My comment was a lame joke ... the best garage is NO Garage

I did notice recently that the light rail line near my house is constructed with some kind of synthetic or composite railroad ties.... maybe something similar is available in Alaska

I am curious how Thorsten built his detached Garage...if he did anything not-so-common

I tell you, I have done the exposed foam twice, the tires never really touch it. If you were really worried about it you could use a piece of PT wider than the foam and either cast it into the concrete or put up with the bump

John B: Oh. I get the joke now. I was referring to a house or two that TC built for others. I need to look at them again and pay close attention to what was done at the garage doors. No, I don't think TC has a garage for his own house. As for “the best garage is NO Garage”, I guess “best” needs definition. See the attached pic. I've been here since '73 w/ no garage, and these lengthy cold snaps, like me, are getting old. The new house will have an attached garage. P, EOS. One thing that some folks don't consider is that parking outside is not free. Anywhere near -10 F and you better have your vehicle plugged in 24-7, just in case you have an emergency (like when my wife lopped off the top of her thumb two weeks ago.) Sure, you can cold start a well-tuned rig down to even -40 (maybe), but it is expensive. At best, you are wearing your engine and polluting like mad. At the worst, you'll spin a crank bearing or bend a conn rod, or won't start and your emergency takes on a new level. Too, even plugged in, rigs are cold at low minuses, and need to idle a bit to warm up. There goes some fuel and more pollution. No doubt about it, though, from a thermal standpoint alone, NO GARAGE. I've seen the synthetic ties lying along tracks; will have to snag a few next time I see them.

Keith: Your idea is interesting, and as I mentioned I had considered extending PT plywood beyond the ramps to the concrete, either recessing it or dealing w/ the bump. Perhaps cutting the span between a concrete apron and the slab to 6” and Tapcon-ing some PT plywood to it would be adequate. It should not be too difficult to recess some PT ply a little bit to eliminate or minimize the bump. It sounds better the more I think of it. Again, thanks to all for the ideas.

Ooops. I missed the file I guess. Here it is.

John K,

Your comments make sense ...and I assumed that Garages were pretty standard up there.

but then I noticed that Thorsten did not have a Garage attached to his house.

I wonder how he deals with the issues you mentioned??

John K, just...wow. Its been a unusually warm winter here in Michigan.....

John B: I am sure TC does what all of us w/ out heated garages do; plug in. I have never tallied up the per cent of folks w/ and w/out garages, so I don't know what "standard" is. Unheated shelters are helpful, esp for frost, but are no substitute for block, oil pan, and transmission pan heaters. When it hits 50 and 60 below (not for a loooong time now), it pains me to think what differentials are dealing with. Aaron: Been a bit more like the early '70's and '80's up here this year. We got spoiled there for several winters. Keith: I have wiggled my design, and have almost eliminated the wood completely. I may even leave it out and see how it goes. Yes, tires don't get down into a 2" gap, maybe even 3", so exposed foam would likely be pretty much an aesthetic thing. I'll find out. Thanks again for the idea.

John, start your foam whatever inches wide you desire and as it rises up separating inside concrete from outside concrete taper the foam to 0" wide. No foam shows to cover and you have a very good thermal break.

Done deal

AJ: OK, that is what it sounded like, but I don't have concrete meeting concrete in a vertical plane, as this suggests. That is why I couldn't quite see how to do that here. I COULD have the slab and apron meet on a vert plane, but then it would have to run the slab out 6" past the door; maybe that's not so bad anyway. After all, the concrete won't be heated the last 4' to the garage door. I would like, though, to keep the concrete "protected", as it were, by the garage door, and have foam outside it from there. Here is the latest permutation, given some of the suggestions above. If the engineer thinks the edge beam will be compromised this way (non-load bearing wall at the garage doors), I'll have to run the slab out 6" to meet the apron and can easily taper the foam as it rises, even leave a 2" gap at the top. That won't hurt stink, as Keith suggested. The "thermal break" area looks awkward here, but it will be really easy to build it in. Either way, I think I'll bag the wood idea.

I would suggest having the door meet the wood, thus wood and foam make the transition inside to out. Being a non-engineer I would think more steel would remove any sins from the edge of the slab.

Keith: Will consider. Whatever the door hits, I want it FLAT, permanently. Thanks.

Is there any reason you can't simply notch back the foam/slab... IT seems like you're assuming the edge of the foam slab, can't jog in, and then back out when it gets to the door.

And then simply have slightly non thermal bridge material cover the edge of the foam that's exterior to the door.

John O: Yes, two reasons I am not (yet) considering notching the slab farther into the garage. (1) I rather prefer to not compromise the edge beam any more than necessary. (2) I'm not quite comfortable having the door come down on foam, or maybe even wood. I am more concerned about air leakage than having more thermal break than what is in the second plan. I may be unnecessarily worried there, though. All ideas will be floated around (probably until the day we pour....). Thanks. john

Per Chandler ... PVC Cut in half pushed onto foam and concrete. No foam showing. No foam showing is the only way to go. And no wood.

Door comes down on PVC. Done deal, start building.

I assume you are talking about PVC pipe.

" No foam showing is the only way to go." Covered w/ PVC certainly would look better at first, but I don't know if PVC will take the cold, and if it is pipe you are talking about, then I see a crud collector on each side; worse than wood. Maybe flat PeTech (sp? Used on the bottom of dog sleds) instead of wood?

"Door comes down on PVC." That may or may not be as easy to get level as concrete is. Thermally better, perhaps, but I don't know about air sealing. Will keep this in mind, though.

AJ: There are no chains on the gates at the border. It's actually warm in summer. Yes, this will be Plan A, subject to revision. Again, thanks for the ideas.

Never had a dog sled. Never will. Would love to visit Alaska though someday.

Good luck with whatever you decide.

We've used the "Energy Edge"product at garage doors and it worked very well. It's only two inches or so of XPS wrapped in a PVC extrusion but a good way to break the slab at the door. You could also split a piece of 4" PVC pipe on a table saw and fit it around 4" of foam and pour it as a screed and expansion break between the slab and apron such that it's just above the surface of the concrete and directly under the garage door weatherstripping.

There are garage doors that hinge as a single non-folding panel that can have additional foam built out on the interior. Designed to be sided on the exterior so the garage door looks like the rest of the exterior siding for that "Batman Experience" I've always wanted to do one with a grape arbor on it at the end of a driveway so I can press a remote on the car and have the hedge lift up and reveal the hidden garage.

Michael: Good to hear your opinion. You mentioned the Energy Edge last year, and I looked into it briefly. Were it warmer here, I'd be inclined to use it, as it would make finishing and insulating a snap. However, PVC (pipe at least) left outside for several years gets very brittle, in my experience. I am inclined to go w/ wood, as it has a pretty good track record in the cold. P Tex is another possibility, or UHMW; ultra-high-molecular-weight polyethylene. It gets glued to the bottom of river boats to help them slide over rocks and the inevitable gravel bar. I need to dig around and see if anyone else up here even considers dinking w/ this. Thorsten would likely know who has.

I just became aware of another product that may suit this situation nicely. See http://www.foamglas.us/ and look for Perinsul HL. The info on the HL was sent to me via a distributor who commented on another thread here. It looks interesting enough to warrant further research on my part. If anyone is familiar w/ it already, pls post what you know. This picture is where I see possibly using the material, and it satisfies a few suggestions that others made earlier and I could not see how to incorporate w/ what I had planned then.

John, I remember this product being discussed at Summer Camp...

and a "warning"

see the comments at this blog

https://www.greenbuildingadvisor.com/blogs/dept/energy-solutions/foamglas-my-new-favorite-insulation-material

(I guess the first try did not happen, so...) John B: Many thanks for the link. The freeze/thaw cycles would be unavoidable in my garage, unless I go to extreme and bizarre measures. So, it is out of the options. I should have searched here first. Oops.

This is the best looking detail I have seen you do. If the foamglas does not work then I would suggest this exact detail, substituting standard foam with a suitable covering. I am thinking wood[ a great insulator in comparison to concrete] but many things come to mind.

On a sidenote, I am in the scribbling phase of a new garage and am thinking about doors, so please keep us[me] informed abut any garage door information you come up with

Keith: This is pretty similar to the original one in this post, but cleaned up a bit, yes. The original thoughts on using wood ramps was somewhat to minimize the cold mass drawing heat from the garage, but that is likely trivial, in hing sight. Substituting a 4x8 or a 2x8 over 100 psi foam for the

Foamglas, as I think Martin suggested long ago, may be an easy and durable solution.

John, a triangle of foam (instead of a rectangle) with 0" top dimension gets the job done and leaves no foam exposed. Great drawings, I just think you are overthinking your detail along with causing issues unnecessarily.