Image Credit: BlueberarsLair / CC BY-ND 2.0 / Flickr

Heat pumps are going through a period of innovation. Ductless heat pumps are more available; cold climate heat pumps have been developed; higher minimum efficiency standards for heat pumps have been established by the U.S. government; and gas-fired heat pumps have been developed.

Heat pumps are generally fairly efficient as they extract heat from the air, even cold air. A typical new heat pump in the United States is on average roughly twice as efficient as electric resistance heat, although performance varies with climate. While heat pumps can be efficient, they are also more expensive than many types of heating systems, and they generally don’t work well at very cold temperatures.

In order to examine which applications are good for obtaining cost-effective energy savings from heat pumps, the American Council for an Energy-Efficient Economy conducted a pair of analyses that we are releasing now. One addresses opportunities to replace electric resistance heat with heat pumps and the other addresses replacing gas furnaces with heat pumps.

Both analyses use data on actual energy consumption in homes throughout the U.S. collected as part of the Energy Information Administration’s Residential Energy Consumption Survey (RECS). Our analysis of the potential for replacing electric resistance heat with heat pumps finds an opportunity to reduce residential sector electricity use nationwide by more than 2%. Additional energy would be saved by using heat pumps instead of gas furnaces in some important applications. Furthermore, multiple analysts see electric heat pumps powered with clean electricity as an important strategy for displacing emissions from in-home combustion of fossil fuels.

Converting from electric resistance heat

For our analysis of converting homes with electric resistance heat to heat pumps, we used data on space heating energy use in a representative sample of nearly 2,000 homes in RECS now using electric resistance heat.

This analysis looked at replacing both electric furnaces (which distribute heat via ducts) and electric baseboard heat (heating coils along the baseboard in each room) with heat pumps. Electric furnaces are particularly common in the South but are uncommon in the north. Nearly 90% of homes with electric furnaces already have central air conditioning. We found that installing a new heat pump at the time the existing central air conditioner needs replacement will generally be cost-effective, with the median simple payback period (time for the energy savings to fully pay back the additional cost) being 4.7 years.

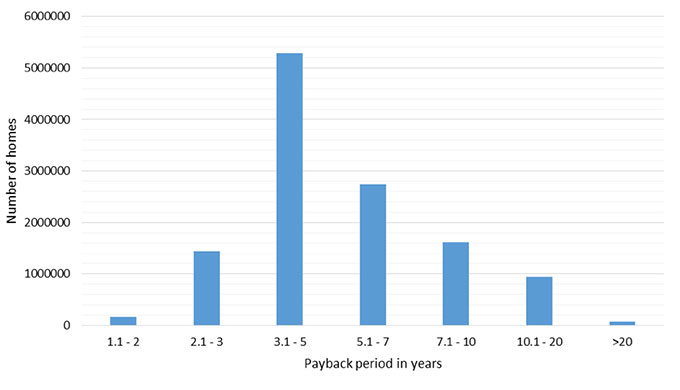

The distribution of simple payback periods is shown in the figure below. Economics were similar for the 17% of homes with electric baseboard heat that also have central air conditioning. But for homes without central air conditioners, the cost to install a heat pump is higher, and the median simple payback was nearly 15 years, although just over 10% of homes have simple payback periods of five years or less.

Replacing gas furnaces

For our analysis of replacing gas furnaces with heat pumps, we looked at average space heating energy use of homes with gas furnaces in each of 20 states. We compared the gas used by gas furnaces with the gas used at the power plant to operate a heat pump. For each state, we looked at a variety of furnace, heat pump, and power plant efficiency levels. We also looked at the relative economics for many of the comparisons.

We found that electric heat pumps generally use less energy in warm states and have moderately positive economics in these states if a heat pump can replace both the furnace and a central air conditioner. Moderately cold states (as far north as Pennsylvania and Massachusetts) can save energy if electricity comes from the highest-efficiency power plants, but from an economic point of view, life-cycle costs for gas furnaces in existing homes will be lower than for heat pumps in these states. (We did not look at new construction where using electric heat and hot water can avoid the need to install gas service.)

For cold states (colder than Massachusetts and Pennsylvania), high-efficiency furnaces use less energy than today’s heat pumps, but further development of cold-temperature electric heat pumps and gas-fired heat pumps will be useful from an energy-saving point of view.

Next steps needed to realizing savings

Based on these analyses, we recommend the following next steps:

- State officials and utilities should conduct further analysis at the state, local, and utility levels. More nuanced analysis at the utility or local level, based on specific rate schedules and climate zones, will more clearly indicate who might benefit from heat pumps and who will not.

- Manufacturers and R&D organizations should continue work to develop good cold-climate electric air-source heat pumps and gas-fired heat pumps.

- Energy efficiency program administrators should consider programs to encourage use of heat pumps in warm states, starting with further localized analysis and proceeding to pilot programs.

More localized analysis is needed, but our analyses find likely opportunities to save energy and money and reduce emissions by using electric heat pumps, particularly in warm states.

Steven Nadel is the executive director of the American Council for an Energy-Efficient Economy. This post originally appeared at the ACEEE website.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

21 Comments

Curious

What's the typical service life of a heat pump?

Response to Chris M

Chris,

According to the U.S. Department of Energy, "The lifespan of a central air conditioner is about 15 to 20 years."

That's probably as good a guess as any for a minisplit heat pump.

A timely article on heat pumps!

This article should be read in conjunction with the long thread on Q and A "do heat pumps and insulation complement or compete."

The article claims a 4.7 year payback when heatpump replaces both air con and baseboard electric, but a 15 year payback when only replacing baseboard. Now my conclusion in the Q and A thread is: "Heat Pumps need to be 50% cheaper, and it is the install fees where that needs to happen" At half the present price the payback is 7.5 years worst case scenario then they compete with natural gas which at present, as this article claims, is cheaper than heat pumps in coldest climates.

The last point: the comparison of heat pump with natural gas electric source vs straight natural gas as heat, needs to be answered by this conclusion: that the source needs to be renewables, and not natural gas...as it does for electric cars. The consumer end needs to be transitioned at the same time as the utility end. Most of this needs to be done by 2030... so gas furnaces are not the answer.

Comparing gas furnace to heat pump on a gas-grid is just wrong.

"We compared the gas used by gas furnaces with the gas used at the power plant to operate a heat pump. For each state, we looked at a variety of furnace, heat pump, and power plant efficiency levels."

Given that almost no state/local grids are 100% gas driven this approach creates a distortion, rendering the result somewhat meaningless. Moving from a gas furnace to a heat pump doesn't mean that gas (either in whole or in part) went into more gas fired power. The model used is far too crude.

"For cold states (colder than Massachusetts and Pennsylvania), high-efficiency furnaces use less energy than today’s heat pumps, but further development of cold-temperature electric heat pumps and gas-fired heat pumps will be useful from an energy-saving point of view."

High efficiency furnaces may use less source energy (a questionable assertion, if the non-gas grid sources were not analyzed), but a furnace certainly uses more gas, and in Massachusetts a gas furnace generates more carbon emissions than a heat pump.

Ven: "Now my conclusion in the Q and A thread is: "Heat Pumps need to be 50% cheaper, and it is the install fees where that needs to happen" "

That may have been your conclusion, but I strongly disagree with both aspects, the price reduction "need", and where cost reductions can or should be made. Show your math.

Reply Dana, math

The math is that, according to this study payback is 15 years for cold climate, if air con is not replaced. The units only last 15 years and so no incentive. If the payback was 7.5 years then there is motivation. Why install rate is where I think the price can fall is because it seems the easiest place for reduction. Perhaps price can fall on the hardware side as well, but not that much. The price reduction "need" is for the sake of big picture climate needs...it is an effective gizmo for accomplishing reductions quickly and easily in houses where PV and Retro are not going to happen.

The installation cost isn't even half the lifecycle cost. @ ven

The majority of the lifecycle cost of a heat pump is the power use. Cutting the installed price of a mini-split by half barely moves the needle on the lifecycle cost or "payback". It's really about average efficiency, and they were not analyzing mini-splits at all (though they gave lip service to one cold-climate mini-split without running the numbers).

This was a study of replacement equipment, replacing an existing gas furnace with a ducted heat pump, (which are typically both higher cost and lower efficiency than mini-splits), and they included a 5% discount rate, etc. The ducted heat pump efficiency in the analysis ranged from 8.2 to 10.5, nowhere near the HSPF 12-14+ range of newer cold climate mini-splits.

The furnace replacement analysis document lives here:

http://aceee.org/sites/default/files/publications/researchreports/a1602.pdf

Also note that since it's all for replacement equipment, not new builds, as stated in this article above:

"We did not look at new construction where using electric heat and hot water can avoid the need to install gas service."

At the bottom of p.11 of the gas furnace replacement document they similarly state:

"As discussed above, our analysis is only for existing homes. The results may be more

positive toward heat pumps for new homes, as most new homes have air-conditioning and

the cost of supplying gas to the home can be avoided by installing heat pumps."

On p.18 they state:

"In cold states, further development of cold-temperature electric heat pumps and gas-fired

heat pumps will be useful from an energy point of view. We did not have enough data to

analyze the economics of these new technologies."

OK, great... no data.

So if a replacement HSPF 8-10 type ducted beastie has a 15 year "payback", are we to assume that an HSPF 13 ductess unit that costs less to install than a new ducted system (any type) has the same "payback". The fact that the lower efficiency ducted units have any payback at all as replacement equipment is enough to hazard that a cheaper, higher efficiency unit would be lifecycle cost competitive for new construction, where the gas-grid hook-up and gas plumbing costs could be avoided.

The overall conclusion that the lifecycle cost of ducted heat pumps is higher than gas furnaces isn't particularly controversial. The presumption about grid generation efficiency and grid mix over the lifecycle of the equipment is- there are big error bars on anybody's best guesses, and they didn't really go into their error analysis or worst case analysis.

I'm not sure where you're going to cut the cost of mini-split (or ducted heat pump) installation by a whole lot unless the office is the contractor's cell phone in the cab of the truck and the labor (ab)used is all minimum wage (or less). There are contractors who will through out crazy high quotes, but you don't have to use them. At $4000/ton all-in it would be on the high side at recent experience (quoted & installed) experience, and $2000/ton wouldn't pay for much more than the equipment for a cold climate mini-split, let alone the overhead costs of running a business and the installation labor.

The most expensive mini-split installation I've been connected with in the past 3 years was 2.75 tons (three separate Mitsubishi FHs) installed for about ~$12K, (which is over $4.3K/ton), installed early last summer when all local installers were crazy-busy, (some not even returning their calls- too busy to get out and quote new projects), and that was a pretty extreme outlier. A superheated summertime market driven by a state subsidy window that was about to close would be my best guess as to why it got that high. Later in the year quotes for cold climate ductless were coming in under $4K/ton in competitive bidding.

Fifteen years is the low end of the anticipated lifecycle for any decent quality heat pump (ducted or ductless). Most will go longer, some much longer, even though it may be economic to swap them out sooner as average efficiencies of new equipment improves.

For completeness, electric resistance replacement equipment analysis document here:

http://aceee.org/sites/default/files/publications/researchreports/a1603.pdf

“Fifteen years is the low end of the anticipated lifecycle for any decent quality heat pump (ducted or ductless). “

......unless, in my experience, it is in a coastal environment. I’ve replaced a number of high quality units at my properties at the 8-10 year mark despite quarterly maintenance.

The math

I showed my work with plenty of math in the related Q&A thread. My thus-far-unchallenged conclusion is that best-of-breed professionally-installed ductless heat pumps make the most sense in locations where it gets very cold, insolation is low, electricity is more expensive than average, and where heating loads are high. I demonstrated how on a per-head basis, inexpensive, low-end, $1,000-per-head heat pumps that can be installed with unskilled labor economically outcompete superior professionally-installed units in my climate (Zone 5B, low load, great insolation, average electricity costs). Finally, I demonstrated how in many other climates, on a per-house basis for an average house needing 4-5 heads (i.e. not a Passivehaus that can get by with only two), the economic return for today's existing cheaper heat pumps is even better than this for builders, who bear only the upfront cost, not the lifecycle cost. Even with higher total lifecycle cost compared to superior units in many locations, today's cheap, easily-installable heat pumps allow builders in not-too-extremely-cold climates (i.e. half the USA) to get a complete HVAC system for a lower upfront price than typical ducted gas furnace+AC installations. That's a net win for the environment, as well as probably for the end user, overall.

This is all a complicated way of saying that if you want people to consume more of something, you need to make it cheaper, which is Ven's point. Cheaper supply -> more demand. We already see this with PV. The lower the price goes, the more of it people buy. Same thing.

Don't look now...

But cheap mini-split heat pumps worldwide probably outsell the first tier Japanese units by large numbers of units. Cheap DIY mini-splits are everywhere, and Mr Cool is just one of several in the US.

The math in this replacement equipment blog article has nothing to do with mini-splits. Read the analysis piece they refer to in the blog. Their best-case heat pump was a ducted unit that tests at HSPF 10.5. Again, it's found here:

http://aceee.org/sites/default/files/publications/researchreports/a1602.pdf

Thanks for those insights (@ Joe Dwyer)

I totally agree that most people never try to optimize if/when the strip heating comes on, to their detriment. Unfortunately it requires a bit more understanding of how the system works and the issues involved than the average homeowner wants to delve into. Even with fairly simple single state programmable thermostats a large number of people never program them, and just turn the thing on/off or bump the override setpoint up and down.

There is probably room in the market for smarter "learning" thermostats for multi-speed/multi-stage heat pumps to deal with the human-learning factor. Most people just want to be comfortable and not spend a bunch of money on heating & cooling, not engineers, or system optimization technicians.

There's a similar problem with condensing hydronic boilers, where the installer sets the outdoor reset temperature curves high enough to never get a call-back from a shivering irate customer, and the homeowner never tweaks it in to find the condensing limits, leaving 10% or more of potential fuel savings on the table.

The ACEEE analysis didn't really get into the effects of equipment oversizing factors either, and didn't specify their assumptions. FSEC-PF-413-04 seems to assume equipment sized exactly for the load per Manual-J (?):

http://www.fsec.ucf.edu/en/publications/html/FSEC-PF-413-04/

Clearly undersizing for the 99% outside design temp would have pretty severe consequences on average efficiency, and oversizing by some modest factor would probably help, as long as heating strip power use was appropriately optimized.

The author responds

I appreciate all the attention this blog is getting. The intent of the blog and the underlying reports was to start a conversation on these issues. Each home and region is different, but our research indicates that there are opportunities to expand use of heat pumps, particularly in the South, and over the longer term, perhaps in the North as well if/when cost-effective cold-climate heat pumps are introduced.

Some of the comments appear to confuse the two different reports that are summarized in the blog. In one report, we look at opportunities to replace electric resistance heat with heat pumps. This analysis looked at using ducted heat pumps in homes that already have ducts and air conditioning, and using ductless heat pumps where there are no ducts. Median simple payback periods are about five years homes that already have ducts and AC, and about 15 years in homes that lack ducts. Yes, we hope that costs might come down in the future, but this will depend on both equipment and installation costs; in my view halving installation costs is unlikely.

The second paper looks at the energy use and economics of converting gas furnaces to heat pumps. The energy analysis used several scenarios for the marginal energy use of the electric grid, ranging from very high renewables to relatively inefficient gas-fired steam turbines. We assumed natural gas for all the non-renewable power both to make the analysis easier, and because most new central generating plants use natural gas. Yes, more detailed analyses should look at the many other generating options. This analysis assumed use of ducted heat pumps since we were looking at replacement of ducted gas furnaces. We did not calculate simple paybacks for these conversions but instead did a lifecycle analysis for each of the system types in each of the 20 states we analyzed. We did not examine new construction, but as previous comments have noted, we did talk about how ductless systems may make sense in new construction so that the cost of installing ducts can be avoided.

Both analyses assume proper sizing and installation. And I agree with the comments that it is generally useful to configure and control heat pump systems in ways that minimize use of strip heat.

Steven Nadel clarification is helpful

"Median simple payback periods are about five years homes that already have ducts and AC, and about 15 years in homes that lack ducts. Yes, we hope that costs might come down in the future, but this will depend on both equipment and installation costs; in my view halving installation costs is unlikely."

Thanks for the clarification. Perhaps halving installation cost is unlikely, just as halving PV soft costs are unlikely, in the U.S., but already accomplished in Germany and Australia. I have no expertise in installations but it seems a lot of money to more than double the price of the machine itself for labor etc.

That is why I thought installation the lowest hanging fruit. The Dept of Energy needs to include these heat pumps in its aspirations as it has done with PV in its "sunshot goal"

Response to Ven Sonata

Ven,

You wrote, "I have no expertise in installations but it seems a lot of money to more than double the price of the machine itself for labor."

In fact, as a very rough rule of thumb, 50% materials and 50% labor costs has been a longstanding principle for many types of construction projects. Of course this rule of thumb is extremely rough, and there are all kinds of exceptions.

Reply to Martin

Yes, certainly in building 50/50 is the norm. But this happens to be a special case. Notice that the government is subsidizing the heck out of green energy. The ITC etc. Large research projects by the DOE as well, many other examples could be brought forward. Why? climate change breathing down our necks. So here we have a technical fix which has very wide application...the heat pump. It breaks even...but people don't think like that on a large enough scale, and basically we can't wait for them to start doing their duty, when they want to "save money". So that is why either subsidies, rebates and other things need to be applied to speed up mass adoption of air source heat pumps or more thought put into quick and easy installs to reduce costs...just as with PV and now with batteries, home ev chargers, and other tech that can be simplified.

Some assumptions need to be squared with reality.

Steven Nadel "Both analyses assume proper sizing and installation."

Sizing of HVAC equipment is almost never correct. With low mass gas or electric furnaces there isn't much impact on efficiency from the typical gross oversizing, but under or oversizing heat pumps has huge consequences on energy use & efficiency (especially undersizing equipment that uses heat strips.)

Marginal power use is NOT universally provided by natural gas generators at average grid-fleet efficiencies, or anything like it. This is particularly true in New England, particularly during peak wintertime loads when the gas-grid & storage capacity is constrained. An increasing reliance on imported hydro and oil-fired peakers is making up the difference, but the regional policy trends seem toward more imported hydro, not more #2 jetters. This is a rapidly moving target, and over the anticipated lifecycle of a heat pump or gas furnace the error bars are large. Using something like the CPP targets for 2020 and 2030 might be closer, but in many locations those hurdles are barely a stripe on the floor, and will be much lower carb by 2030 than required. Of course where it actually goes is going to be steered heavily by both federal & state policymakers.

ven sonata: "Perhaps halving installation cost is unlikely, just as halving PV soft costs are unlikely, in the U.S., but already accomplished in Germany and Australia."

Soft costs have already come down considerably in the US in the past decade, and there is PLENTY of fat in the current soft costs that can be cut pretty easily. This level of pessimism regarding PV soft costs is unwarranted. The US can and will get there. There are counties in US where the average price fro rooftop solar is $2/watt, and others where it's $6. Where there are few regulatory impediments it can be pretty cheap without subsidy. (In some locations the subsidies themselves have been keeping prices from falling.)

In contrast to PV, heat pumps (ducted or ductless) is a mature industry both in the world and in the US, though the ductless market in the US is still on the young-ish side compared to ducted heat pumps. Total installed costs have been falling incrementally in regions where ductless systems have become more mainstream, but the notion that it could be cut by half without cutting into quality/longevity seems overly optimistic.

Sizing, Modulation, and Rebates

Oversizing is still very common in the HVAC industry. My neighbor's new system is 3 tons of capacity for the exact same house design as ours, even with a 15% higher HSPF heat pump. A manual-J wasn't done for him or us. I feel that our old HP is sized perfectly for heating to cover 99%, and with hugely over sized heat strips that are almost never used as backup. My neighbor could have gone with a 2 ton unit for much better efficiency and cost savings, but he never asked me. At least his 36K unit modulates down to 12.6K with the variable speed compressor, but it still cycles on and off a lot due to oversizing, which is a shame.

The next generation split units that modulate down to app. 20% of full capacity will improve efficiency for many who upgrade their systems. Even so, HVAC companies can't live in the past and use seat of pants estimates or warehouse inventory to decide capacity. They need to ask questions about insulation and air sealing upgrades and even look at past electricity bills to determine app. loads. Maybe required training to participate in any customer rebate program?

Utility efficiency programs in this area favor the high efficiency mini-split units right now with $1K rebate for units over 23 SEER. The split units only qualify for $500 rebate, even if they have the same HSPF of 10-13. The obsession with SEER for marketing, rebates, etc. in heating dominated areas shows the broad ignorance of heat pumps in society. FWIW, our utility has excess generation capacity year round.

My only suggestion for the companies who make the equipment, and the associated standards boards, is to have "eco buttons" so typical consumers can just make one or two simple adjustments on the thermostat to save energy and money. The latest Wi-Fi or large display touch screen thermostats that show energy use and costs to consumer are a great start compared to our old 2001 programmable thermostat. That said, I still had to go into "hidden" settings on my neighbor's new touch screen thermostat to engage energy savings options similar to mine. He happily reported being #1 for lowest monthly energy use of 100 similar homes after the adjustments on his new heat pump.

What is the marginal electricity source? (@ Joe Dwyer)

"FWIW, our utility has excess generation capacity year round."

As does just about every other utility. The question relevant to the heat pump discussion is:

What fuel is burned to support the marginal increase in grid load when a gas furnace is replaced by a heat pump? In MN that might be mostly natural gas as of last winter, but increasingly it's coming from excess overnight wind power that has to be exported used or curtailed on windy winter nights. The rate at which wind is getting built in MN is pretty fast, which makes sense given the size of the resource and the now firmed up tax policy support. Within the lifecycle of the HVAC equipment it's likely that nearly all overnight power in the upper midwest will be coming from wind.

Minnesota's Renewabilty Portfolio Standard committment is for 25% of all power to be supplied by new renewables by 2025. But since a large fraction of that is being met by wind power, wind is likely to become half or more of the overnight power source by 2025. Cheap wind with zero (or negative, due to the PTC) marginal operating cost is making large inflexible power generators with large fixed costs such as nukes and thermal coal uneconomic in the midwest, and cutting into capacity factors even on the more nimble gas fired generation.

Swapping a gas furnace for a heat pumps to provide a load during the wintertime overnight may have negligible on the amount of natural gas burned for power in the era of cheap & ubiquitous wind, even if by Steven Nadel's analysis the heat pump may be less natural gas efficient using fixed assumptions.

I Agree (@ Dana Dorsett)

Until the EV revolution really takes off, the upper Midwest will have lots of surplus? and inexpensive wind energy at night coming very soon. MidAmerican Energy in IA expects wind energy to cover 85% of customer sales in a few short years. I see this as a great way to transition away from NG heating, which I believe is bound to go up in price again in the not so distant future. If electricity is cheap enough at night, then resistance air or water heaters/hydro heater may also make sense. I do see the second generation 200 mile EVs coming this Fall and next year as having a much greater adoption rate and adding loads at night. All of this is likely moving faster than the historically conservative predictions related to energy production type and use.

I only mentioned utility over capacity because it appears that some or most utility rebates for heat pumps are modeled after AC units where the logic is a bigger rebate for greater SEER rated equipment because of the perceived or evidenced summer peak loads nearing or exceeding utility capacity. The mini splits currently win on SEER, but are about the same on HSPF rating versus Greenspeed type split models. Interestingly, our utility had 2014 peak summer load of 1,095 MW and winter 2014 peak load of 953 MW, with 22% reserve margin. This will grow to 30% when one industrial customer starts a NG CHP operation next year.

Our mostly coal fired utility is regulated, so they are allowed to sell up to their combined generating capacity, plus much smaller firm purchase supply (wind) capacity. So even with relatively cheap wind energy available wholesale, our marginal electricity generation here is 98% coal and 2% gas peaker. This doesn't help my argument for heat pumps where I live, other than being better than strip heat where no NG is available to the customer.

It's easier to size mini-splits than a GreenSpeed. @ Joe Dwyer

The GreenSpeed has only a 2.5:1 turn down ratio, which gives it a fairly narrow window for sizing it such that it modulates enough to hit it's HSPF numbers. Most mini-splits have much higher ratios, and wider modulation range overall, which makes it easier to actually hit (or sometimes exceed) their numbers in-situ due to extremely high part-load efficiency.

The wind target is moving faster than I can keep track of in the upper Midwest. Now that high capacity factor wind has a lower levelized cost than new combined cycle gas a lot of it is going in outside of state RPS requirements. MN is one of the very few states that has a long term standard for remuneration for PV, but since the utilities (rather than the PV customer) has the option of net metering rather than paying the solar tariff most have opted for the simplicity and lower cost (for now) of net metering, which is giving residential scale PV a slower start in MN than in higher electricity price states.

A carbon tax could tip the rational finance balance sooner, but the learning rate of PV is pretty fast, with the installed price more than 10% per year for residential rooftop solar. MN's "Community Solar Garden" approach looks primed to grow in the next five years too, not that it has a huge impact on space heating load grid peaks, which happen mostly at night or shortly after dawn when waking humans &/or setback thermostats all step the temps back up.

These are Conservative Estimates

We've been using a split heat pump (single stage, air source, 13 SEER/8.5 HSPF, 2.5 ton capacity) for 15 years now and it's still going strong with a scroll compressor. I consider myself well versed on this subject, so here are some points of contention with this study.

Publication FSEC-PF-413-04, which this study uses as a basis, attempts to improve the AHRI ratings to reflect "real life" energy use. This results in some significant down ratings in colder climates like Minneapolis (41% reduction in HSPF), but also upratings in mild climates like Los Angeles (33% improvement in HSPF).

I believe this study doesn't go far enough to test the "high efficiency" options available with most split heat pumps. For example, our split heat pump is set to NOT use any electric strip heat during the defrost cycle (similar to AHRI standard) and also for any temperature above 5F (dissimilar to AHRI standard). This past winter wasn't quite as cold and strip heat never came on (AHRI zone 4). The previous winter it came on only a few times for short periods with "aux" mode to supplement the HP when the temps. hit -5F to -10F on a few early mornings. These settings have great ramifications on total energy use as the heat pump is app. 2.4 kW and the strips are staged from 5kW- 15kW. I really need to install a TED system or timer this next winter to calculate the actual HSPF factor of our HP. I believe it's very close to the rating of 8.5, even with our average 24 hour thermostat setting of 67 F (higher than AHRI standard of 65F).

One might say that most people don't adjust the "hidden" settings in the thermostat and just let the unit run as set up by the manufacturer and HVAC installers for maximum comfort (i.e. lots of aux strip heat). This is likely true, just as some people don't run their hybrid car or HPWH in "eco" mode. But why not test units with the low energy options engaged to show what is possible? I believe if this is done, then the results of this study will definitely shift to the heat pump as the winner, even with a 50% dirty energy source.

As far as installed price, our unit was app. $1,800 per ton in 2001. It replaced an old A/C unit and electric furnace. My neighbor recently installed a new 10 HSPF/21 SEER split unit and the price was the same per ton, which is pretty amazing considering the increased efficiency. Our area has strong competition for standard HVAC, but I see very few mini splits.

Our home is a split level circa 1982, so not extremely tight. We have upgraded the attic insulation to R-60+ and also have newish dual pane vinyl windows, but nothing out of the ordinary.

The 'all or nothing' nature of debates over ASHP vs. Gas I have found somewhat misleading. Many consumers/home owners would embrace a phased approach where an ASHP system can be bought as two halves of a split system, HE gas furnace/air-handler first, that is designed to support an ASHP when their existing AC needs to be replaced.

Split systems include hybrid options, so as a house is made more energy efficient over time - a high capital cost item, the HVAC gear has been designed to go zero emission later on, so gas can simply be switched off and the ASHP component can be made to do all of the work. We have seen renos where the TEDI has dropped by 70% of the original load. Not everyone can afford to do that work before they change equipment. https://www.thomsonarchitecture.ca/2021/02/09/future-heating/

Log in or create an account to post a comment.

Sign up Log in