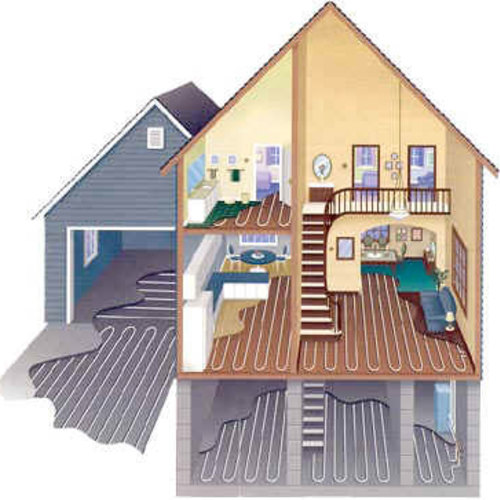

Embedding a heat source in a surface to create radiant-heated floors, walls, or even ceilings isn’t a new idea. Although electric resistance has been used as the heat source, the most common set-up is hydronic heat. In this system, a boiler supplies hot water to plastic tubing (often PEX) that’s encased in a concrete floor. Much has been written about radiant heat; a good primer on the subject is Martin Holladay’s “All About Radiant Floors.”

Frequent poster “jollygreenshortguy” (Jolly) writes in this community forum post that he is building a new house, slab on grade with a hydronic floor heating system. He’s looking for opinions on where to put the heat source. He presents two options:

- Place the floor heat piping with the rebar before the slab is poured, which is the more common, one-step approach. The disadvantage to this option is that if repairs are ever required, the slab has to be broken up. Also, the tubing is at risk of damage during construction. Efficiency-wise, heat has to pass from the tubing through the entire slab before reaching the house interior.

- Place the floor heat tubing on top of the slab, then embed both the tubing and the slab in a 1-1/2-in. topping of poured gypsum underlayment (if the floor is tile or wood), or concrete for a finished concrete floor. This method can happen later in the construction sequence, posing less risk of damage; and if the tubing does need repair, the topping slab is the only barrier. Located near the surface, the tubing also has a faster response time. The only disadvantage that he sees is the need for a second concrete pour.

Which option for hydronic floor heat is best for Jolly? That’s the topic for this Spotlight.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

2 Comments

I have designed hundreds of radiant floor systems in the west and taught design and installation around the country between 1984 and 1989 with sponsorship of manufacturers and the Radiant Panel Association (now the Radiant Professionals Alliance). I agree with Ryan that attaching it to rebar is just fine, but it should be kept within an inch or two of the slab surface. Having a design layout is critical so that the proper lengths are maintained for automatic flow balance and the risk of damage to tubing when shooting down interior wall plates is eliminated.

Completed in 2000, my home includes radiant heating and cooling. Part of the floor is carpeted and in this Northern California climate there has been no problem with moisture damage due to condensation. Minimizing peak cooling load has become important, both for minimizing time-of-use utility costs, as well as reducing carbon emissions from peaker plants. I run the cooling system (an air conditioner converted to a chiller) in the morning when outdoor temperatures are low and condenser efficiency is high, and coast through and maintain comfort during hot afternoons. I use a simple thermostat that cycles the system on and off to maintain a slab surface temperature that exactly meets the load. Now, we have packaged variable speed air-to-water heat pumps (AWHPs) that modulate to maintain a fixed water temperature.

I am working on a project that will compare the cost and efficiency of radiant heating and cooling to forced air systems with attic ducts, and based on my experience I believe radiant with packaged AWHPs will be a winner once the trades become accustomed to putting it in. -David Springer

Great info! I like the "spaghetti special," ha!

Structurally, concrete should fully encase the rebar when possible, so ideally I'd like to see the tubing tied to perpendicular rebar, not tied along the length of a rebar, where the concrete will have less grip. But for most residential slabs it's probably not a big deal.

Log in or become a member to post a comment.

Sign up Log in