Missing a detail when working through an unfamiliar assembly is easy to do. Getting your head around air and water movement and the thermal boundary with all of the parts and pieces that are required to build a sound structure often requires more information than can be shown in a simple plan or elevation drawing. I often find myself drawing in 3D using a modeling software. Sometimes I go as far as building a mock-up of the assembly. Other times both are needed.

If you are an architect, you’ll have the software tools to make professional, photo-realistic drawings. I’m not an architect but I have some formal training in drafting, which I received decades ago, when CAD was brand-new and my instructor was a proponent of drawing by hand before moving onto computer-generated drawings. Some of my past designs were done on paper or with an inexpensive CAD program, which can work, but they are not very impressive when trying to sell a client on a design. Since then, I have started using SketchUp for more information-rich, useful, and polished drawings.

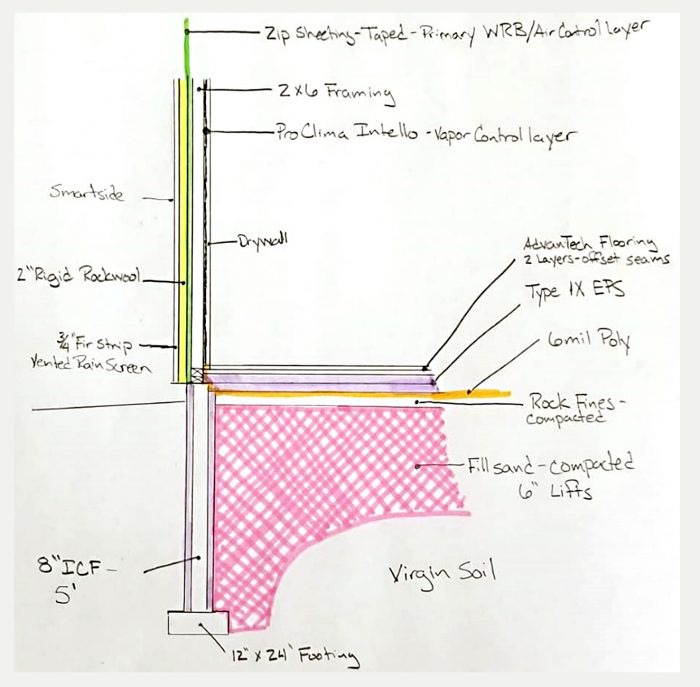

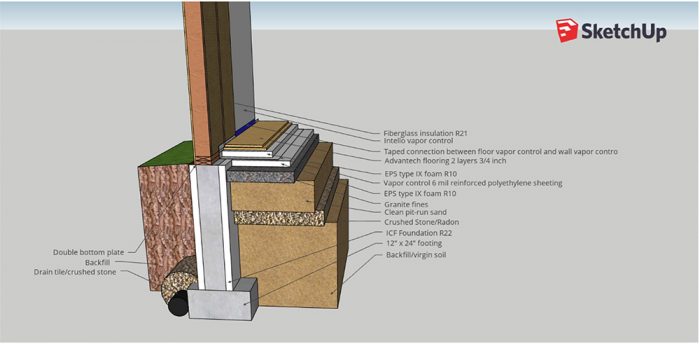

The above hand drawing is my original design for a concrete-free slab-on-grade home showing the floor system. Later, with the help of SketchUp, the design was transformed to this:

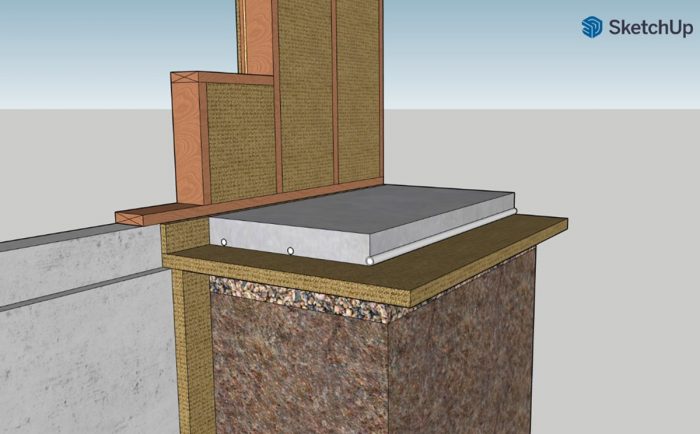

In SketchUp, I can draw exactly how the assembly is to be built. I start at the foundation and move up, adding in the different layers as I go. There are probably more efficient ways to design, but this process works for me—and other builders I know—as I think through the sequencing.

I have no formal training around using SketchUp—I’ve just watched a few YouTube videos; and I am using the free version. With a little practice, the software can take less time to produce an image than would drawing the same level of detail by hand. The improved drawings work to get my ideas across to both builders and their team members, and they help sell the homeowner on my design ideas.

I also find 3D modeling helpful in my role as an energy auditor. Often homeowners aren’t familiar with building terminology and a picture is useful.

For example, I used the above illustration to show a homeowner how exterior insulation can work on both a wall and the roof. This also happens to be the same model used for the sub-slab rigid mineral wool insulation with in-floor heat detail. The software makes it easy to modify one illustration to fit the needs of another project.

Sometimes though, it is a good idea to move beyond a drawing and into an actual model.

Building a mock-up of an assembly allows a builder (and me, as the designer) to work with the products and materials that will be used in the actual build. I took this approach the first time I used Zip System sheathing, tapes, and fluid-applied products.

This not only helped me figure out how to work with the materials (for example how to apply Zip’s Liquid Flash) but also helped in sequencing the assembly. The photo of the completed mock-up (main image) shows an early design for the concrete-free slab-on-grade project. I didn’t like how a few of the products were working together, so I made several changes that improved the finished project. Those changes may not have happened if I hadn’t built the mock-up and learned from the experience.

Building a mock-up can also be helpful if you include the team who will be working on the project. Again, they may not be familiar with the different products that will be used. The mock-up allows them to gain some experience—a bit like an on-site training seminar. This training may include the architect or designer, the project manager or foreman, and could even include a rep from the manufacturer supplying the materials. I think it is best to have the manufacturer provide the training, whenever possible—their success depends on your success.

_________________________________________________________________________

Randy Williams is a builder and energy rater based in Grand Rapids, Minnesota. Photos courtesy of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

6 Comments

Thank you for this Randy. If its not against any terms or use or site rules, can you post links to the youtube videos you found the most helpful?

Hey Allen,

I watched the official Sketchup YouTube channel, the New to SketchUp? series. That series got me enough information to fumble my way through. I only create a few drawings a year, if I used it more, I would take more time to become more efficient at using the program.

Awesome post.

Perhaps animated gifs of the construction of the mockup would be useful? I'm thinking primarily of the short videos (<1 m) that now often accompany social media posts of recipes, often shot from above a chopping board or pan. Check them out at https://tastygifrecipes.com/

More examples here: https://www.makeuseof.com/visual-recipe-sites-learn-how-to-cook-gifs-videos/

I think the key to these is they show just the illustrative snippets, tightly edited, and in sequence. You really get the scale of ingredients in ways that text doesn't convey.

I think this style of video could be a super handy reference and easy to share via a QR code posted on site. They are short enough that just watching the whole thing is easier than searching for the particular bit you need (but drill downs into specific parts could be hosted too).

Speaking of that, sharing websites via a QR code is awesome, waaaay easier than texting someone a link or having them type in a URL. Works on Chrome on Android and desktop OS, but not yet easy in Safari on iOS. https://support.google.com/chrome/answer/9979877?hl=en&co=GENIE.Platform%3DAndroid

I can see this being much easier to share instructions etc on job sites, especially across languages.

One thing that needs working out is what role these mock-ups, 3d sketches or gifs would play as part of the contract documents. They may be very useful as explanatory material, but right now I don't think there is any mechanism to get a contractor to follow them.

You see the same problem with the youtube videos manufacturers post showing how to use their products. They may have explanatory value, but don't form part of the installation instructions that ensure code conformance or warranty approval.

For showing the design/layout of a whole house or addition, it helps to visualize the space in three dimensions, and be able to "walk through" the space. Home Designer Suite $99 (or free version) has lots of built-in objects to add to a design, and once the floor plan is laid out with lots of realistic objects, you can see 3D mockups like these illustrations. Various companies provide libraries of their products to add to your design (e.g., Trex, James-Hardie, Corian, Jenn-Air, Delta, Therma-Tru, Sherwin-Williams, Wayfair). However it lacks the ability to get into construction details shown in the Sketch-Up drawings, except maybe the expensive Chief Architect versions. Home Designer might be better for builders doing new construction and wanting clients to be able to visualize a home layout. Or maybe suggest the client or DIY builder get the software and mock up their dream home, addition or renovation.

Down here in TX, on large projects is common to see mock-ups, however, I think is a waste of time, materials and effort, since our Builders do not install materials to learn “how is done”.

I usually create a 4’x8’ front yard sign that shows a mock-up, and once is done, the posts and sign can be reuse on the next project. I also use 3D pictures in my Builder and Subs orientation (aka Design Charrette)

Log in or create an account to post a comment.

Sign up Log in