If you want in-depth coverage of the intricacies of insulating roofs, whether the insulation is on top of the roof deck, on the underside, or both, Martin Holladay has lots of information for you here at GBA. As I’ve been writing a book on this stuff lately, I’ve been working hard to get at the essence of the principles of building science and their applications, and that includes these hybrid roof assemblies. One of the terms that’s tossed around in discussions of this topic is “ratio rule,” so today I’ll give you just the basic facts about it. If you want to go deeper, I’ve got some links for you at the bottom of this article.

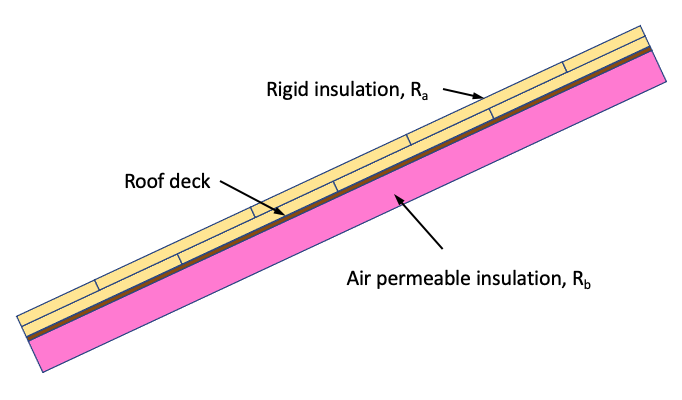

The ratio rule I’m discussing here applies to hybrid roof assemblies with two kinds of insulation, some of it above the roof deck and some below. (It could also apply to roofs with two kinds of insulation beneath the roof deck, with the upper one being air impermeable and the lower one being air permeable.) Typically, the insulation above the roof deck is rigid foam, but it could be mineral wool or some other type. The diagram below shows the configuration. The ratio rule tells you what percentage of the total R-value of insulation you need to put above the roof deck.

The reason for the ratio rule is that you can’t just put any combination of R-values above and below the roof deck. Well, you probably can in warmer climates (zones 1 to 3), but the colder the climate, the more you have to pay attention to the ratio of above- and below-deck insulation. Why? Because of the temperature of the roof deck in winter.

If you put all the insulation on top of the roof deck, you have no problem because the the roof deck stays nice and warm. If you put all the insulation below the roof deck (and do it properly), again, you have no problem. The roof deck stays cold, but you keep the water vapor from inside the house away from the roof deck.

So, insulation on top raises the temperature of the roof deck and insulation below lowers the temperature. The science behind the ratio rule is to keep the roof-deck temperature high enough that it doesn’t accumulate enough water to cause moisture problems. Yes, there is actually science behind the ratio rule. But the numbers they settled on in the model code are a combination of science and politics.

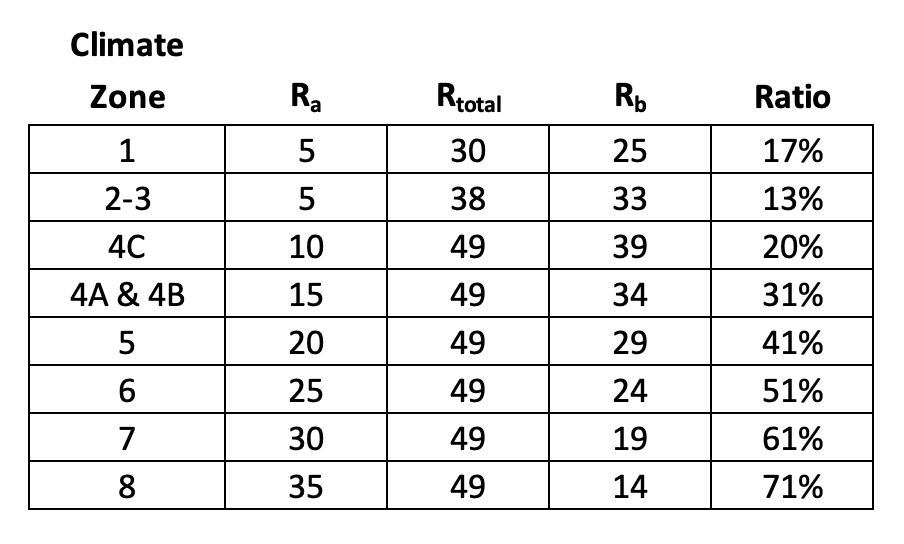

The table above shows the ratios needed. If you’re doing the the code-minimum insulation for a roof (the middle column, Rtotal), you don’t need to worry about the percentage. Just make sure you have the minimum R-value required (second column, Ra) above the roof deck. The percentages (last column) apply when you’re doing an insulated roof with above-code total R-value.

One more note about this kind of hybrid assembly: The model code around this issue is about air-permeable insulation (e.g., fiberglass, mineral wool, cellulose), but the same science holds for air-impermeable, vapor-permeable insulation. That is, open-cell spray foam, as shown in the lead photo above.

That’s probably the shortest explanation of this topic you’re going to find anywhere. If you want to go deeper, my first recommendation is Joe Lstiburek’s article, “Hybrid Assemblies”. If you want even more (and are a GBA Prime member), Martin Holladay has covered this topic extensively in several articles. A good starting place would be “Combining Exterior Rigid Foam With Fluffy Insulation”“. (And be sure to check out the comments, especially anything from Dana Dorsett.)

____________________________________________________________

Allison Bailes of Atlanta, Georgia, is a speaker, writer, building science consultant, and the founder of Energy Vanguard. He has a PhD in physics and writes the Energy Vanguard Blog. He is also writing a book on building science. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

29 Comments

" Typically, the insulation above the roof deck is rigid foam, but it could be mineral wool or some other type. "

So is this simply about the ratios relative to the roof deck, and the air-and vapour permeability of the above deck insulation doesn't matter?

R-total and the derived ratios vary with the year of the code and the method used (R49 isn't always correct for Z4-8) . With above sheathing insulation, avoid the ambiguity by using this:

b. Alternatively, sufficient continuous insulation shall be installed directly above the structural roof sheathing to maintain the monthly average temperature of the underside of the structural roof sheathing above 45°F (7°C). For calculation purposes, an interior air temperature of 68°F (20°C) is assumed and the exterior air temperature is assumed to be the monthly average outside air temperature of the three coldest months.

Thanks Jon,

I bring it up partly because the discussions on GBA about exterior insulation on walls have yielded differing opinions on whether the type of insulation matters. If I recall correctly, Martin answered a question about that by saying the thickness of insulation outboard of the wall sheathing wasn't important if mineral wool boards were used, while Ben Bogie said he still thinks the ratios apply as the insulation is dense enough to slow down drying.

> air-and vapour permeability of the above deck insulation doesn't matter

Practically, it's unlikely to matter. But say you had a vent channel above the above deck insulation and permeable underlayment. Then above sheathing mineral wool would produce an assembly that has a) warm structural sheathing and b) significant ability to dry outward. This is more resilient than say foil faced foam that only has a). On the other hand, "more resilient" usually isn't needed.

Similar logic applies to walls. Apply enough exterior foam and the ability to dry outwards is a usually unnecessary supplement. But I'd take the free extra insurance of say unfaced EPS vs foil faced.

+1 (What Jon said!!)

When using vapor & air permeable insulation above the roof deck the average winter temperature of the roof deck is sufficiently above the presumptive average indoor dew points and it's moisture content stays low as long as the R-ratio is preserved, and it is adequately protected from bulk water from above. That makes it useful to have a vent channel above the permeable exterior insulation as drying path for any bulk water/rain penetration that gets by the roofing layer.

> bulk water/rain penetration that gets by the roofing layer

Which is probably a question of when not if. If this happens, different designs will vary in terms of repair-ability.

Jon,

I differ from you , Martin, and Dana in that I have enough confidence in the metal roofs I install that I don't anticipate them ever leaking - although I don't design my roof assemblies based on that assumption.

Dana, my understanding is that the amount of insulation on top of the roof deck should be sufficient to keep the deck temperature above indoor dew point regardless of whether the insulation on top is air or vapor permeable. Are you suggesting it's different?

How do you calculate what R-value above the roof deck will keep the sheathing at 45 F (7C) if you have for example R-10 below the deck and the 3 coldest months have an average temperature of 16F (-9 C)?

I'm in zone 5, so 41% of my insulation value should be above the deck.

Code in Ontario is R-50 for conventional attics / R-60 if above an electrically heated space, but for cathedral ceilings like the one in question code is only R-31.

If my roof will be R-36 (peculiar limitations prevent higher)

41% x R-36 = R-14.76 should be above deck.

But that doesn't make use of the 16 F / -9 C average temperature of the coldest 3 months.

Did I miss something?

R-values are set for more reasons than moisture control, so is the 41% of R-36 method an accurate way to find what amount of insulation keeps your roof deck at 45 F (or above) ?

The image in this article shows the temperature profile through a wall assembly: https://www.greenbuildingadvisor.com/article/the-flash-and-batt-method. (Side note, I drew the original image but FHB redrew it for an article, and it was repurposed here.) It doesn't make a big difference what the interior or exterior temperatures are. If the insulation is uniform through the assembly, you can just draw a straight line from exterior sheathing to interior finish; if it's 0° outside and 70° inside, halfway through the wall the temperature will halfway between the two, or 35°. When you have different types of insulation as in the flash-and-batt example pictured it's a little trickier, but not much--if 1/3 the total R-value is in the foam, at the interior side of the foam, the temperature will be close to 1/3 of the difference between interior and exterior. For the example of 0° outside and 70° inside, that surface will be about 23.3°.

Plotting the temperature profile through an assembly isn't a perfect science, as air leaks, installation quality, the R-value of the sheathing and claddings, air films (an insulating layer directly adjacent to surfaces) and night sky radiation all affect the calculations. But it gets you close.

Then you compare that to the psychrometric chart to see what combinations of temperature and relative humidity will result in condensation.

In your case, you have 41% of the insulation in the impermeable layer. Using an outdoor design temperature of 16°F and indoor design temp of 70°F the difference, or delta T, is 54°F. 41% of that, or 22°F, is handled by your foam layer, leaving the interior surface of the foam--the condensing surface--at about 38°F. (16° + 22°.)

Then go to the psychrometric chart (or use software) (https://www.greenbuildingadvisor.com/article/how-to-use-the-psychrometric-chart) to find that a 38°F surface will condense if 70°F air at about 33% relative humidity reaches it. That's a pretty low RH level so you would not want much room air to contact that surface. That's why the IRC still requires a class 3 vapor retarder even if you meet the prescribed ratio, to slow indoor air from reaching the condensing surface. Even then, many pros find prescriptive ratios a bit risky.

Indoor air at 70°F and 50% RH, as some people prefer for comfort, will condense if it reaches a 51°F surface. How do you design a wall to to keep the condensing surface warmer than that? If your outdoor design temp is again 16°F, and indoors is 70°, 51° is 65% of the difference. So you would need 65% of the insulation to be in the outer, impermeable layer. With a total of R-36, that means R-23 foam and R-13 "fluffy" insulation. A rule of thumb to be extra-safe in cold climates is to keep 2/3 of the R-value on the exterior, which is pretty close to the math here. But because vapor retarders do their job pretty well, in most cases it's ok to "cheat" the math by using code-derived ratios.

Thank you!!!

Wow, awesome explanation!

For the 45F method, this is approximately correct:

(45 - Tavg) / (68 - Tavg) * Rtotal = Rabove

“[Deleted]”

The ratios also matter for below-code-minimum levels of insulation, as the temperature profile through the assembly is pretty consistent, regardless of total R-value.

“[Deleted]”

“[Deleted]”

Why use the "monthly average outside air temperature of the 3 coldest months"? Why not the coldest month? The 3 coldest days?

Also, by "average", the meaning is not average daily highs, nor average daily lows, but average overall, right? Why not use the average lows?

The aim is "to maintain the monthly average temperature of the sheathing above [dew point]." Does that assume that three weeks of temperatures below dew point (year after year) is not long enough to do damage?

Yes, be sure to use monthly averages, which doesn't involve highs or lows.

Why this value is a question for those involved in writing this code. Correct, some amount of time with the sheathing below the dew point doesn't accumulate damaging moisture.

With code-complaint vapor retarders and air-sealing, the idea is that moist air won't be freely circulating into the framing cavities, so it's not important what the short-term conditions are. Vapor movement via diffusion is very slow but it does happen. And from what I understand they aren't trying to prevent 100% of the potential moisture accumulation, just enough that it can dry before causing problems.

QUESTION,

My understanding of the hybrid method is that regardless of your desired total R-Value that maintaining the correct ratio is the key, so that as you increase the warm side R Value you must increase the cold side accordingly.

MY question is , can I increase the cold side R Value without having to increase the warm side? This obviously changes the ratio but is it as important when doing so from the cold side?

Generally, you can put as much R-value as you want on the topside of the roof. We are trying to keep the winter temperature of the sheathing above the dewpoint of the interior air. The warmer the sheathing, the lower the risk. So, more insulation outside lowers the risk and even more is even better.

Conversely, and as I asked in my reply #16 (above), is there a risk in using, for example, 7" of closed cell foam 'below' the roof deck, as the home builder only offers the 1/2" Zip R sheathing,

User... 421,

Yes you can use foam below the roof deck. See this link:

https://www.greenbuildingadvisor.com/article/five-cathedral-ceilings-that-work

However if this is a new build, why not choose a roof assembly that doesn't need foam at all?

Thank you again for the valuable information, and yes, I can discuss non-foam options with my builder. Getting information from the modular home manufacturer has been like pulling teeth, but they do offer the 1/2" Zip R. It's still a good idea (about $2K extra), regardless of insulation choice below roof deck, correct?

So if closed cell spray foam is used on the inside, there is no ratio to worry about?

On my rooftop deck, my builder was supposed to do R30+ EPS above and R20 closed cell spray foam below. I didn't like the idea of closed cell spray foam, but I allowed it because it was in the garage. (I don't like it because if the roof leaks the water will be trapped, and I get seriously ill from mold.) Anyway they screwed up and didn't put much EPS above. They are proposing to instead use more closed cell spray foam below.

Now on the other hand, if they also didn't follow the ratio over the shop where I didn't allowspray foam so the interior insulation is Rockwool, then that must follow the ratio. Right?

it depends if you use closed or open foam..

If you use only closed foam above like 2" thickness then you are safe - because the sheating will not see water vapor - you just need enough foam to get the R you want.

If you use some other insulation inside of the foam, then the ratio still applies - you do not want condensation on the inner face of the new foam.

Check: if you add some open insulation below the new foam, then consider the ratio of "new foam + EPS" against the R of the new fluffy insulation --> THAT ratio has also be ok.

Any surface temperature below the dew point is in danger if water vapor can get there, that is the rule of thumb!

Thanks, but sorry I'm not sure which scenario you're addressing. If there's a little EPS above, and a lot of closed cell spray foam below, is there risk of condensation?

Ok if you can’t achieve an adequate ratio, should you forgo the above deck insulation ? Or is it a con ti umm of risk ? If if code designated ration is say 31% in zone 4, what if you cna only achiev e say 25% or 20% ? Re same ration in wall situations ive never gotten a clear answer . Ie if you cnat get close to proper ratio, juts bag gthe exterior insulation, on USG go down in wall framing say from 6 in to 4 inches then you have achieve d this ratio > soem. Though say ANY ext insulation is better than. NONE….

Log in or create an account to post a comment.

Sign up Log in