A few years ago, I performed a blower-door test on a new house with a small footprint of 1130 sq. ft. The results indicated an air leakage rate of 91 CFM at the test pressure of 50 Pascals—that’s .33 ACH50, which was unexpected for this code-built house. I actually measured the house volume again and ran the test two more times before I was convinced I had accurate results.

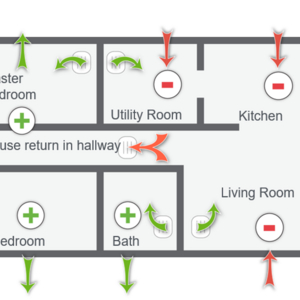

Later, the contractor contacted me to report the homeowners were noticing air coming through the exterior light switches when the dryer was operating. The dryer was producing close to the same negative pressure as my blower door every time it was being used—a negative pressure of about 50 Pascals. Is this a problem?

As with just about every building science question, the answer is: It depends. Let’s start with the risks.

Negative pressure in a hot-humid climate can lead to comfort issues. The exfiltrating air may be replaced by hot and humid outside air that will require conditioning, increasing the required energy needed to maintain comfort. Depending on where the outside air is entering, there could be the issue of condensation on exterior walls, air conditioning ducts, and even cold waterlines. This can affect both the durability of the structure and indoor air quality.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

Cold-climate homes can also have issues related to negative pressures including decreased comfort, increased energy costs, and extremely low indoor humidity levels during the winter months. I’ve even seen the formation of frost on the inside of exterior walls where air is leaking into a home.

Homes in all climates may see backdrafting of fossil fuel–burning appliances if the home goes negative. Another concern is the pulling of air from attached structures such…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

24 Comments

Randy,

Like Allison I feel like make-up air is a topic hovering in the background waiting for our attention. What I am completely at sea on is what an appropriate response might be. Temperamentally I'd prefer to see effective passive air-intakes used, but maybe this will be solved through control changes to unbalance ERV/HRVs - or perhaps each appliance that can cause de-pressurization should be designed to deal with it?

Luckily the problem isn't as pressing in the benign climate I build in where the energy penalty for cracking a window or simply having a few passive air-intakes isn't very high.

Malcom,

I've thought about this a bit lately too - I think with the coming era of the smart home, there ought to be an easy way to tie appliances together, so that everything just works behind the scenes, similar to how we just set the thermostat and the rest functions without us.

An oven could trigger an associated ERV to go into unbalanced mode to supply more air, which boost to the kitchen. A bathroom exhaust could do the same, etc. I think bringing in air in a central location where it could still be conditioned is a good idea, but it has to be transparent or an occupant will never bother.

Kyle,

It brings up a number of issues around how much integrated tech we want, or should require in a house. I see a real gulf between the average houses people live in in North America, and the houses GBA readers might aspire to. I'd like to see a couple of acceptable solutions ranging from what you describe to the other end of the spectrum where they don't rely on smart devices at all.

I like to think of a solution similar to the 'connected fire alarms' level of complexity. They're hard wired with low voltage cable, and that seems sufficient. Similarly for thermostats, they're hard wired to the unit and that isn't overly complex. If we could somehow manage to have an interface between ovens, ervs, range hoods, bathrooms fans, and the like, with a common RJ45 or similar connection, I think it could go a long way in transparent automation.

Malcom and Kyle,

This is the conversation I was hoping for. Should we be conducting a worse case negative pressure testing to determine building pressures after the build and incorporate properly sized make-up air systems to reduce risks, or are these risks simply perceived? Are the exhausting devices providing proper performance? If a dryer is designed to exhaust 150 CFM, what happens if the house limits it to 75 CFM? Dry time will be extended, but is there also a risk of the equipment failing early because of less heat dissipation? Is there a fire risk? Like Gary said, less than 100 CFM50 could be a problem. I think it's important to ask these questions.

I have been working on an HRV retrofit using two EC fans, both controlled via automation (Leviton 0-10V dimmer + Hubitat)

As predicted, unbalancing does affect efficiency, but running positive pressure (by about 40 CFM) does completely stop back smoking when loading our high efficiency fireplace (which has outside combustion air feed). I've also got our kitchen hood exhaust inline EC fan "talking" to the HRV which also changes the ventilation behaviour. I suspect it's the future of smarter ventilation :-)

Quite a few have mentioned that kitchen exhaust only works if used..and found this quite true in our home. To that end, I added ~$190 worth of automation bits so that power use detected on the induction cook top controls an inline EC exhaust fan. Once you have both systems automated, then everything else is just a few mouse clicks and automation rules.

I have temperature probes in the air streams so you can view live data from the system:

https://www.hundredgraphs.com/public/denwood

Attached are the results of unbalancing about stale vs fresh (and vice versa) by about 40 CFM:

Hey Dennis, super interested in how you’re getting the positive 40cfm into the space?

My house is very tight; I’ve never tested but I know now because I’ve just built an addition on the side of the house… I put a fan in that moves air into the addition so that it benefits from the wood stove in winter; and a passive exit for that air back into the main living space to try and balance the pressure. The stove is a blaze king that can run real low. It also has a fresh air intake.

With the inter-room fan running; despite the fact that the air can move back into the source-room via the hole I’ve put in, I believe I’m getting negative pressure where the stove is as we get a CO alarm go off when the stove has almost burned out. So there’s not enough heat and pressure to push the fumes up the flue anymore.

I’ve toyed with the idea of adding another fan on the exit of the addition so the fans act in pairs but would prefer not to… or something that kicks in when there’s a pressure drop.

What are you using please? 😊

Andy, sorry for missing your question. I'm using AC infinity and Terrabloom ECM fans, with 0-10 volt control. They are all automated via Hubitat. The ECM fans are very efficient, particularly at slower speeds.

https://community.hubitat.com/t/success-0-10-volt-control-of-ac-infinity-or-any-ec-fan-motor-using-leviton-zs057-d0z-zigbee-dimmer-or-zooz-zen54-zwave-0-10v-dimmer/104450/79

So far I can confirm that Fantech, AC Infinity and Terrabloom ECM fans will work fine with this type of control. Zooz now (launched in Q1 2023) sells the Zen54 0-10 volt "micro-relay", as well as the Leviton that I had originally experimented with. Both are zWave devices, so wireless with respect to control.

The Messana ATU (HRV) has an extractor mode which compensates for unbalanced flow. This would require placing a current meter on a kitchen exhaust to raise the contact. It ramps down the exhaust ECM fan and increases the inflow ECM fan.

In the two energy positive houses I built I put in Fantech Fancm3000 kitchen exhaust fans, located outside the building envelope to reduce noise and a 2nd Fantech Fanrvf6, also outside the envelope to push the same air the exhaust fan volume back into the house, through a hydronic heat exchanger to heat or cool the air to the building set temp.

I also installed a Zehnder Comfoair 200 which has a fireplace boost function that makes up the dryer air. Bathroom fans are through the Zehnder HRV and heat and hot water are heat pump with electric boiler backup.

Are you sure about that? Zehnder originally told us that their systems could supply limited amounts of makeup air, like for a dryer. But the more we dug into it, the actually people in Germany said it would not.

Correction. He added this: "On the other hand, a CA200/350/550 unit will very slightly improve a negative pressure in a house since it will let more supply flowrate be sucked into the house while the exhaust is reduced (doesn’t rebalance the fans)."

So you're finding that "very slight" amount is helpful?

Get a heat-pump dryer, that doesn't vent conditioned air to the outside, and an electric or induction stove-top, which doesn't need a hood to ventilate inadequately burned gas by-products out into unconditioned space. Then add a HRV for fresh air all the time.

Has anyone studied the impact of negative house pressure on an ERV? Many experts have stated an ERV shouldn’t be relied on for makeup air, but that overlooks the obvious: an ERV that is running provides a significant “path of least resistance” for outside air, and will be thrown out of balance. Efficiency will decline, but it doesn’t go to zero. The supply fan will effectively experience a reduction in static pressure, the return fan will experience an increase. Will this harm an ERV? Manufacturers must consider this when specifying fans for their units. How much imbalance can the motors tolerate? Will ECMs be more or less vulnerable to the effects of the imbalance? If we shouldn’t rely on ERVs for makeup air, is it because they can’t supply enough makeup air? Or is the concern that the motors will be harmed? Perhaps both concerns are valid? If anyone can provide some additional insight, it will be greatly appreciated!

I was originally told by the Zehnder salesperson that it would allow a certain amount of makeup air, say 100 cfm for a dryer. But we kept pressing and eventually the guys in Germany said it would not. He said:

"My understanding is that the Q will always try to balance the supply flow with the exhaust (internal to the HRV), but it won’t balance a house that’s under a negative pressure from a range hood or dryer (won’t add make-up air). When a range hood (external influence) is turned on it will cause a negative pressure in the house and the HRV’s flowrates will change. Due to this negative pressure and prior to rebalancing the flowrates, the supply flowrate will increase (air more easily will be sucked into the house) and the exhaust will decrease. The Q HRV will readjust flowrates to rebalance the supply flow through the HRV with the exhaust through it (not the house)."

I recently heard of another brand that just came out with one that claims to do some make-up air.

Sure, I've studied this issue. Running an otherwise balancing ERV in a negatively pressurised house will increase fresh air supply a bit, but not so much that you would see any difference in core efficiency as the ERV running fans etc. have a fair bit of static pressure already. I've only tested this with a 100 pascal differential (negative) as that is as much as I could generate without a blower door.

My kitchen exhaust fan (inline ECM) is automated via current sensing on the induction cook top's power use. It ramps according to power use on the cook top. The HRV setup also compensates (about 60 CFM now) by using an asymetric flow profile that increases fresh air supply to around 100 CFM and reduces stale air flow to about 40 CFM. This does change the core's heat exchange efficiency down to about 50% (vs the norm of around 78%) so on a very cold day (with an ERV, colder than -10 C), you could run the risk of freezing up the core if run for a very long time this way. I have tested this setup over the winter (with temps below -25 C) and have seen no issues as my setup dynamically varies defrost/recirc based on outside temps and monitors core warming.

We also have a high efficiency fireplace, and about 40 CFM asymetric flow pretty much stops any back puffing during loading.

I suspect you'll see a manufacturer marketing this feature sooner than later, but I had to resort to my own control setup to do it. As I said before, you do need to account for operation in very cold temps this way...and you do end up reducing core efficiency a lot. However, I also have post heating and MERV 13 filtration on the HRV system, so at least the inbound air is "managed" vs just dumping via a makeup system.

Ramping based on induction stove current is a good idea, but rather imperfect. Bring a big pot of water up to boiling requires no exhaust (with electric--with gas you'd want exhaust for sure), but when you are frying on lower heat, you'd want substantial exhaust.

Dennis, could I ask you for more information about your high efficiency fireplace? We’re currently having a (hopefully) tight house designed that will have an induction stove, ASHP, ERV and (hopefully high efficiency) wood burning fireplace.

Henry, sure. It's a Napoleon non catalytic. It's not a new unit, but uses secondary combustion, has a large glass door and puts out 60K BTU. It will easily heat the entire home (about 2600 including basement). I've done a heat load calc based on actual NG use and the home needs 26-28K BTU at -17F so we have be careful not to overheat if using the fireplace. Once up to temp, there is pretty much zero indication at the chimney that a fire is burning. This particular unit has outside air for combustion, so the only issue with using it in a tight home is a moment of potential back puffing when you open the door to load it. The asymetric HRV profile works great to stop this.

As the house has increased in efficiency, we use the fireplace less and less. You may want to look at your house insurance rates with and without the fireplace and decide if you really will use it a lot. When the power goes out at -25 C (not often) or the one time our condensing furnace threw a code (again in very cold weather), the fireplace certainly takes the stress off.

The wood for this unit comes almost exclusively from trim cuts of the 20 odd trees on our city lot, or wood scraps from the shop. A burn will pretty much last all night with a load of 4-5 split pieces of wood.

You will only be able to purchase EPA units I suspect if purchasing now, so you can take a look here: https://cfpub.epa.gov/oarweb/woodstove/index.cfm?fuseaction=app.searchResults

You'll be at around 80 % efficiency with a secondary burn stove, and a bit higher if you go with a hybrid that adds in catalytic tertiary combustion.

Thanks so much Dennis. My wife says no to a wood stove or fireplace with insert. She wants the ambience of a traditional fireplace. But I can hopefully persuade her to accept something like the Uptown 600 with a guillotine glass door & screen or Rumford 1000, both from Renaissance Fireplaces. Emergency heat will be peace of mind as well. Shore of Georgian Bay, climate zone 6.

It’s great to see home automation being put to such effective use! So it’s feasible, for sure, especially with Hubitat and an AC Infinity hack. That leaves two questions … how efficient and how safe is overdrawing air past the fan motor(s) in an ERV? How did you guys arrive at an estimate of 50% efficiency? And apologies if I seem overly cautious but I’m pretty sure you’d violate a warranty encouraging a motor to repeatedly rev-up beyond spec. Unless, perhaps, an ECM would somehow reduce its power draw (share the load with another fan in the airstream) and enjoy the free ride? The bearings might eventually protest….

Dr, pretty sure the warranty card has long sailed :-) I was given an older Venmar unit with a burnt motor, now removed. I'm running two external ECM fans where previous there was just one internal. You can call this a science experiment if you'd like.

There is little danger of over driving a motor as the static restrictions in an ERV/HRV, given the exterior hoods, core, flex lines, filtration, and ducting is a lot higher than you'd see in a house being pulling negative/positive. The motors will always be seeing static pressure. Also, the ECM motor strategy to correlate CFM (on a self balancing ERV) is to measure current...so it would just use a little less or more current based on the house pressure.

I have temp probes on the four air streams, so calculate efficiency live from the unit using the standard temperature equation: https://www.engineeringtoolbox.com/heat-recovery-efficiency-d_201.html

50% efficiency is calculated from live data when the unit is running the asymetric profile for the kitchen exhaust.

The Hubitat dashboard displays live efficiency from the unit which helps identify things like a frosted up exhaust during a -35C cold snap. In that case efficiency was abnormally low due to the restriction in stale air exhaust. Ice had built up at the exhaust flap. I figured how to address this by running exhaust only for 15 minutes once a day which melts any build up.

I also use the temp data (along with air flow) to dynamically manage wattage to the inline PTC heaters. It's easy to figure that out if you know the starting temp, target temp, and CFM values. Post exchanger heated air temps (fresh air supply) are rock solid based on that setup.

I've added some other tweaks like continuously variable defrost times (based on outside temps), as well as variable speed recirc. (when core temps recover). I'm guessing a lot of this may become mainstream at some point as it's all about reducing power use. It's not AI, just common sense in my book :-)

Pics etc. here : https://www.garagejournal.com/forum/threads/super-efficient-hrv-retrofit-with-smoke-filter-for-300.505161/

Sorry for all the tech gibberish...I have learned way more than I had intended on this particular rabbit hole.

Charlie, that's a good point. The baseline is a measured 110 CFM (running the fan at about 50%) which I've tested as the best mix of capture efficiency vs noise. At 50% the inline fan (with a duct muffler) is quiet, and nearly 100% of cooking vapours are captured. The fan speed will not go less than that, however I can ramp up to 100% when there are multiple pots etc. on the stove. 100% is about 160 CFM.

The other reason you can't ramp directly to the induction cook top instantaneous power is that it will maintain a given heat setting by oscillating power levels to the induction coils...so the Hubitat rule is set to ignore power readings under 250 watts or so.

We do want the exhaust running with liquids, particularly in summer.

The other plus of the setup is that we're using Broan EcoVents which are basically a foam ball in an insulated housing that "pops" up when the vent is under pressure. The problem with these vents is that at very cold temps, the ball can freeze a bit in place. Running the fan at 100% does pop the ball after a minute or two. Having an ECM fan with some intelligence behind it means that I can run the fan at 100% for 120 seconds (if outside temps are below freezing) then after that it will dial back to 50% and ramp up if needed. The Terrabloom 6" ECM fan can generate much more static pressure then your typical exhaust fan..and also has a metal housing so is perfect for this application. At .5 in w.g. it's flowing 250 CFM with power use at 33 watts. It's a pretty cool setup :-)

The HRV setup just switches over to the asymmetric profile while the kitchen exhaust fan is running to provide makeup air ~ 60-70 CFM. Once I update the HRV building terminations from 4" to 6", I should be able to tweak 100 CFM from it.

Henry, with a large glass door, you'll be pretty amazed by the intensity of radiant heat you'll get by the fireplace..with zero smoke or spark issues. My wife, two daughters and two cats love it. I grew up with a traditional fireplace and the whole issue of freezing right beside it due to cold drafts goes away 100% with the new units. Your biggest issue will likely be over heating in an efficient home.

The only issue you'll see likely will be that slight back puff when you open the door (slowly) to reload. Crack a window/door, or figure an asymetric boost ERV/HRV setup and you'll be fine.

You'll have issues 100% if you go with an open fireplace in a tight home, requiring an open window which kind of defeats the purpose. Take your wife if you can to a showroom which actually has an EPA type sealed glass door fireplace...you'll use miles less wood, have a smokeless unit, and have a ton of heat as well.

Log in or become a member to post a comment.

Sign up Log in