Image Credit: Mr. Mike

A GBA reader who calls himself “Mr. Mike” is working on an 11-ft. by 14-ft. addition to his house in central New York that sits some 5 feet off the ground. The space beneath the addition is a great place to park a lawnmower, but it’s also open to the cold.

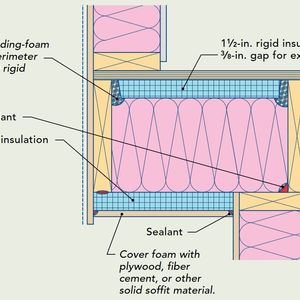

The floor joists are supported by two beams, each a tripled 2×10. To insulate the floor, Mr. Mike put two layers of R-13 unfaced fiberglass batts in the joist cavities, ran a 3/4-in. layer of Cellofoam foil-faced rigid insulation over the bottoms of the joists, then covered the insulation with 1/2-in. oriented strand board (OSB) to keep out pests. The subflooring is 3/4-in. tongue-and-groove plywood.

All seemed to be well until Mr. Mike got ready to install strip flooring in the addition.

“When I pulled the existing carpet up to redo the floor, I made a couple of access holes to inspect the cavity and found signs of frost and condensation on the foam insulation — but only in certain areas, closer to where the addition is attached to the house,” Mr. Mike writes in a post at Green Building Advisor’s Q&A forum.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

The flooring manufacturer has recommended a layer of #15 asphalt felt between the strip flooring and the subfloor, but Mr. Mike is concerned this may trap moisture in the floor system, making the situation worse than it already is.

Should he remove the foam and re-install the OSB? Add more foam to the bottom of the floor system? Insulate the tops of the 2×10 beams with foam?

Those questions are the start of this installment of Q&A Spotlight.

Make the foam thicker and seal the air leaks

To David Meiland, this problem seems to be caused either by the insufficient R-value of the rigid foam…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

43 Comments

Air Space Affecting Floor Temperature

I am somewhat puzzled as to how reducing the insulation thickness and leaving an air space in its place makes the floor warmer. Although perhaps that is the wrong interpretation of the claim.

Here is what I see: As the floor in this case currently exists, there is thermal bridging through the joists which will create “stripes” in the floor that are colder than the area between the stripes.

So if you leave an air space below the floor, it will be heated by the heat loss; and that warmed air space will transfer heat by convection to the sides of the joists which are exposed in the air space. So this will increase the temperature of the cold stripes on top of the floor while slightly decreasing the temperature of the area between the cold stripes on top of the floor.

Therefore, on average, the floor gets colder; but that average temperature will be more uniform between the colder area above each joist and the warmer area between joists.

Cold floors

Cold floors are a result of air leakage, thermal bridging and too little insulation. The floor truss design also plays a role in making floors over unheated spaces comfortable. Rooms built over garages on older homes in cold climates are notorious for air leakage and cold floors. All use dimensional lumber for floor trusses, probably 2x10's. The insulation install is often suspect and the biggest drawback is lack of attention to the rim joist area. The stack effect insures a steady and cold flow of air through this type floor system during the heating season.

If I build a new room over an unheated space I use open web floor trusses at least 16" in height. I also seal the rim joist area with several layers of Thermax fit tightly and air sealed. The 16" space is blown full of insulation for an R-value approaching 50. The floor above this configuration will be warm, the open web trusses due to the triangulation have a long, interupted path from cold to warm and minimize the thermal bridge.

Response to Ron Keagle

Ron,

I just got off the phone with Joe Lstiburek. He admits that leaving the air space above the insulation results in greater heat flow and thus (to a limited degree) more energy use. But the result is more comfortable.

If the joist bays are completely filled with insulation, the difference in temperature between the subfloor directly above a joist and the subfloor above the center of a joist bay will be 1.5 degrees F. (This is because of thermal bridging through the joists.) According to Joe Lstiburek, if you leave an air space above the insulation, the difference in temperature between the two locations is 0.5 degree F, which is less noticeable and therefore more comfortable.

In you install a continuous layer of rigid foam insulation across the underside of the joists, you get the best of both worlds -- plenty of R-value, and no cold spots above the joists due to thermal bridging.

Joe wanted me to emphasize that he is not advocating for less insulation -- only for improved comfort. The continuous layer of rigid insulation is the key to getting both.

Response to Martin Holladay

Martin,

Thanks for that clarification. That seems to confirm my interpretation expressed in my first post above. It evens out the temperature difference between the floor area over the joists and the floor area between the joists.

I assume that when the air space changes the noted temperature difference from 1.5 to .5, it does so by the combination of raising the temperature above the joists and reducing the temperature of the floor between the joists. This is because the added heat over the joists has to come from somewhere because the heat conducting effect of the joist remains unchanged. So heat is simply added to the warm side of the thermal bridge, and that added heat comes from the heat lost through the floor between the joists.

Thus, I assume that while the difference between the warm and cold areas of the floor is reduced, the average temperature of the floor is also reduced. That would explain why when Joe Lstiburek says the floor becomes more comfortable, he also stipulates that the energy loss increases.

I agree that the optimum solution is to minimize the thermal bridging by using enough foam board over the joists on the bottom side.

Bobby Darin...splish,splash

Bobby Darin...splish,splash this! 1.5°F and .5°F...Martin,it sounds like Lstiburek has debunked his own myth with those figures.Peter,don't go ripping up that floor yet.I don't think Mrs.Yost will be impressed

with the results.

What about a vapor barrier in floor? Does the foam stop vapor and prevent hardwood floor from cupping?

John,

Most floor assemblies include a layer of plywood or OSB (the subfloor). Plywood and OSB are both vapor retarders, so floor assemblies already have a layer to control vapor flow.

Hardwood flooring can cup if the moisture conditions on one side of the flooring are different from moisture conditions on the other side. This situation could occur in a hot, humid climate, especially if (1) the floor assembly has a board subfloor instead of an OSB or plywood subfloor, and (2) the materials on the exterior side of the floor insulation are vapor-permeable, and (3) the outdoor temperature conditions are hot and humid, and (4) the indoor conditions are dry and cool due to air conditioning.

In this situation, a continuous layer of rigid foam on the exterior side of the floor joists would be very beneficial and should prevent the problem. In general, a continuous layer of exterior rigid foam is always good, and has no downside.

Thanks so much for the instant reply. That’s what I suspected.

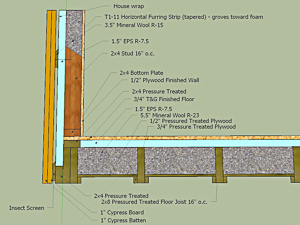

We're planning an addition to our home on Martha's Vineyard, which I've discussed before (Climate Zone 5). The master bedroom with wood floors will be on tall piers over outdoor space. We will certainly be walking on the floor with bare feet and will not want it to feel colder than adjoining spaces, Structure is going to be 9-1/2 TJI's whose thin cross section will probably reduce thermal bridging somewhat. I was planning to use about 7-1/2" of open cell foam insulation....I can also add some board insulation below (probably only 1") or leave an air space on top. Are we destined to have a floor that feels perceptibly colder whatever we do unless we install some radiant heating (probably low voltage electric) in the floor assembly?

Hugh,

7.5" of open cell insulation gives you an R-value of about R-28. That's close to the code minimum of R-30. But that's just a minimum. If you used 9.5" of dense packed cellulose, you'd get over R-30 at a lower price. Add an inch of foil-faced polyiso with taped seams and you've got another R6 plus a good air and vapor barrier, and it reduces even the small amount of thermal bridging of the I-joist webs. Going a bit above code for this type of assembly will help warm up the floors. The more the floor is insulated, the more closely its temperature will track the rest of the space.

"Add an inch of foil-faced polyiso with taped seams and you've got another R6 plus a good air and vapor barrier, and it reduces even the small amount of thermal bridging of the I-joist webs."

Any issues with taped seams creating a second vapor barrier?

I'm still confused a little about vapor barriers when using permeable insulation, whether cellulose or open cell foam. The old school in me says put the vapor barrier to the interior, but when insulating a floor and adding an inch of foil-faced polyiso with taped seams under the floor joists, the vapor barrier (as well as air barrier) is at the exterior. Isn't it then possible that if the polyiso is less than 40% (climate zone 5) of the total insulation that there might be condensation on the top of the polyiso from moisture laden air within the house?

Here are good vapor retarder/ext perms/foam thickness recommendations (see side bar 2 which applies to floors):

https://www.buildingscience.com/documents/digests/bsd-106-understanding-vapor-barriers

> there might be condensation

There definitely will be with thin enough foam. Do the math with your coldest temperature and the right internal humidity - but realize that a small amount of condensation/sorption isn't a problem, especially when exterior perms allow some outward drying (foil doesn't). Ignore hand waving and follow the Building Science recommendations!

With vapor diffusion, up or down doesn't matter - drive will be from wet to dry (inside to outside in Winter). Air flow is different.

Hugh,

It would only be a problem if the vapour drive was to the exterior, but a floor doesn't have that. You don't see problems with exposed floors with rigid insulation on the underside.

The vapor permeance of a 3/4" plywood subfloor is pretty low, (and thus protective), but I'd still be reluctant to put thin foil faced goods on the underside of R30 in MV. Unfaced or fiber faced foam works fine, and has at least a comparable vapor permeance to the subfloor, for at least SOME drying capacity toward the exterior.

To the question:

"Isn't it then possible that if the polyiso is less than 40% (climate zone 5) of the total insulation that there might be condensation on the top of the polyiso from moisture laden air within the house?"

That's a resounding "NO!"

The 40% number is from the IRC prescriptives for unvented roofs in zone 5 without interior vapor retarders. Roof are exposed to nighttime radiative cooling down to a very cold outdoor dew point in winter, averaging colder than the ambient air temperature. Unless the ground under the house gets as cold as deep space (in which case hell has frozen over, for all practical purposes :-) ) you're going to be able to get away with less- a LOT less.

The IRC prescriptive exterior R for walls without interior side vapor retarders in zone 5 is ~27-28%, but even that would be generous for an assembly that's facing the ground, which will average several degrees warmer than the ambient outdoor air temperature in winter, on a surface that gets no direct wetting from rain/snow.

But with a ~ 3/4" subfloor you HAVE a Class II vapor retarder already in place (<0.5 perms when dry), and can get away with even thinner foam. In winter when it really matters, stack effects will be causing warm moist conditioned space air to RISE, the opposite direction of what it takes to push that humid air through the floor to condense on cooler surfaces. The combination of low vapor permeance subfloor and stack effect drive offers quite a bit of forgiveness.

Dana,

Thanks....I guess my concern wasn't so stupid regarding the comment I received in August from Peter Engle who said "Add an inch of foil-faced polyiso with taped seams and you've got another R6 plus a good air and vapor barrier."

You've cleared up things with your comment "but I'd still be reluctant to put thin foil faced goods on the underside of R30 in MV. " It looks like I'm pretty good to go with the 3/4" plywood subfloor, a 1-1/2" airspace (per Joe Lstiburek), 8" of cellulose, fiberglass, etc.. and 1" of unfaced foam below the TJI's covered with plywood. On balance, what what would be your specific recommendation for the 8" insulation and foam board with cost as a factor, but more importantly performance and longevity? and is it advisable to install an air barrier between plywood and foam? or install plywood with sealant or cover strips at seams?

Hugh,

According to Martin, Joe L. later resiled from his suggestion about the air space. Any time you use batt insulation you want it encapsulated on all six sides.

If I used an air space....and I do like the concept of moving the floor surface into the "conditioned space" with the bottom of the air space (at bottom of top TJI flange) being a foam board which would encapsulate whatever insulation (blown cellulose, fiberglass) was below it.

Re foam cut to fit between joists

A shame to do more work and create thermal bridging and air leaks (as compared to continuous taped foam) in the process. I expect that foam on top of the joists and some wood plugs (through the foam) to transfer weight from the sub flooring to the joists would work. It could also be that wider joist flange widths and the right density foam would avoid foam compression without plugs.

I wouldn't bother with an air gap, it will have almost no effect. Even more so with continuous foam (above or below) reducing thermal bridging.

Jon...thanks, but I don't see where I'm creating thermal bridging. If anything I've reduced the effect of it at the finish floor by "warming" the top joist flange in the air space. And whether or not, a wider flange and the right density foam would allow compression on top of joists, I would always install the plywood subfloor directly on top of the joists in order for the floor to be structurally sound and rigid by forming a diaphragm.

Jon,

I think this is a new build. Adding foam on top of the joists would mean a difference in floor level, and some interesting decisions about how to handle bottom plates at the exterior walls. Wood plugs to support the subfloor...

All that to avoid putting the foam under the joists?

“[Deleted]”

Hugh,

Sorry I missed your followup question. Dana explained pretty well why the risk of downward vapor drive is lower than up. Yes, there is some small risk of condensation on the top of the polyiso with only 1" and R-30 on top, but the risk is low. You could eliminate the risk by going to 1.5" or 2" polyiso if you want, though I don't really think it necessary in your location. I like the air barrier performance and durability of the foil facing on the underside of flooring, so that's my preferred treatment.

A significant exception would be in salt-air coastal zones. If you are very close to the water, the underside gets exposed to salt fog and that can corrode the foil facing in relatively short order. Fleece-faced polyiso would probably be better, covered with a rugged finish material.

>"On balance, what what would be your specific recommendation for the 8" insulation and foam board with cost as a factor, but more importantly performance and longevity?"

In MV I'd skip the 1.5" air space and make it 9.5". It's not cold enough to matter in MV, especially with the lower thermal bridging of the thin web of the TJI plus the foam thermal break on the bottom. Seriously- the air gap makes sense in places that hit -20F every winter in floors build on standard milled lumber joists and no foam thermal breaks, but not your assembly. In your case the air space just creates a potential thermal bypass.

3lbs cellulose works for the fluff, unless 1.8lbs fiberglass comes in cheaper. At 9.5" cellulose comes in at ~R35, 1.8lbs fiberglass comes in at ~R40.

For the foam, an inch of unfaced Type-VIII (R4.15) or Type II (R4.2) EPS works, but could be a PITA to work with. Fiber faced roofing foam (R5.7). The EPS would cut the thermal bridging by about 1/4, the polyiso by about 1/3. But in truth, with R35 or more in TJIs the foam hardly matters- it's hard to justify the cost on either a performance or comfort basis.

For an air barrier, tape the seams of the foam, and stagger those seams with those of the plywood, also taped.

As an alternative to foam + plywood sheathing, two layers of 3/4" asphalted fiberboard (~R2 per layer) on the bottom would give a thermal break comparable to an inch of Type-I EPS. Fiberboard is fairly vapor open, highly moisture tolerant, and would have the better drying potential. Tape the seams of each layers and stagger the seams of the layers for best air tightness. At 1.5" it's rigid enough to tolerate dense packing pressures for 3lb cellulose, but not necessarily for 4lbs. Use cap screws through-screwed to the TJI flanges for the final bottom layer.

I like the idea of using asphalted fiberboard. Nobody uses that around here anymore and I rarely see it. Is it still in common use in New England? What type of tape would you use for the seams? WOuld you follow it with furring and a ceiling finish?

Siga Wigluv is alleged to stick well to asphalted fiberboard (and wax infused fiberboard) using Siga's Docskin primer. I haven't used it (but would.)

The seams of the first layer can probably be a cheaper housewrap tape, since it's going to be sandwiched-in by the next layer, and not exposed to any sort of weather. (The bottom layer's tape needs to not peel off in hurricane force winds.)

If you don't mind looking at asphalted fiberboard it's fine to just leave it exposed- it needs no finish to protect it. If you want to paint it use a type that it asphalted only on one side, and turn the non-asphalted side to the exterior.

I don't know who is selling it in MA anymore, but you might be able to find a Blue Ridge/Celotex distributor here:

https://www.blueridgefiberboard.com/locate-a-distributor/

It's unfortunate that MSL's SonoClimat ECO4 isn't available in the US, since it comes with a reasonably attractive green spray-applied WRB that might look better than dark asphalt from below.

https://www.mslfibre.com/Upload/Documentation/T12670-106_SONOclimat_ECO4_En_08-14636585404223102286.pdf

(Feel like driving a truck to/from Quebec? :-) )

When these guys get rolling in Maine there may be Euro-style fiberboard insulating sheathing available on this side of the border:

https://golab.us/ (Scroll down- they're targeting availability January 2021)

https://www.mainebiz.biz/article/go-lab-lands-250k-grant-to-test-and-market-its-disruptive-fiberboard-insulation

https://www.greenbuildingadvisor.com/article/fiberboard-insulation-developer-takes-step-forward

They haven't published any product specs yet, but fiberboard isn't super complicated product, and has a long successful history- they'll probably get it right.

I did a quick internet check. looks like 1/2" asphalted fiberboard is available here and there, but I didn't find any 3/4". ...1/2" material makes me a little nervous regarding possible sagging over time unless some type of "contact cement" would allow lamination into an effectively 1" or 1-1/2" panel that might be more rigid.

Dana

Thanks for the suggestions. The portion of our addition over the open space will be a new master bedroom with heart pine (new) floors so we're concerned about how it will feel with bare feet. That's why the air space seemed to make sense. I'll follow your suggestions but give your contact info to my wife so she can go after you instead of me when she gets out of a warm bed on a 15 degree morning and her feet hit the floor.

I will definitely look into the asphalted fiberboard. The underside of the addition will actually not have much visibility. Although it's fairly high off the ground, it's basically hanging out over an underbrush area, that won't have much occupancy. We'd been thinking about going with a pine tar pitch for the siding (like the Blue Heron House) to more differentiate whats's a contemporary addition from the existing white cedar shingle main house. So a "black" bottom works for us (regardless of how we end up with the siding). I'll look into various hurricane proof tapes but would want something that is black or near black, or paintable, and will stay stuck indefinitely.

Siga makes a black version of Wigluv tape that should work if you go with asphalted fiberboard:

https://www.siga-store.com/Siga-Wigluv-black/en

Home Depot sells half-inch asphalted fiberboard in some stores, but shipping to your local store doesn't seem to be an option on the website. (Three layers of half inch would be about R4 too.)

A low voltage mesh electric radiant floor on a timer set to come on an hour or two before the alarm clock can do wonders for keeping even the most sensitive toes happy & warm, but I'm not sure I'd be willing to pay for that extra bit of cush on an R35+ floor. YMMV.

Hugh,

According to Joe L. (Martin's post #3 above), leaving the air-space will make the subfloor 1 degree F warmer than if the bays are completely filled. I wonder if that is discernible - even for someone with sensitive feet?

Also note that the unevenness goes down considerably when you measure where it counts - on the upper floor surface.

I am insulating floor joists which are over an exposed space (post and pad construction, with no crawl space or basement beneath. Directly above earth.) I have plywood on the underside of the joists to retard the movement of cold outdoor air into my building, through the floor. This also makes it easy to fill the cavity from above rather than underneath. I was planning to stuff the cavity with batt insulation to prevent cold air from filtering into the building. I would use ridgid foam if it were cheaply available, but as it is I have a lot of leftover batt insulation. I have read a lot about how it is important to completely block the movement of air within the building. But that contradicts my previous understanding that, in my temperate marine climate (coastal British Columbia) air flow is necessary for drying in the wall/floor/ceiling cavities. Old houses are still standing because they are drafty, essentially, and can dry easily. They say one of the oldest problems of building is how to keep moisture from entering, but also to allow it to dry when it enters(which it invariably will). So what is your recommendation on the treatment of my floor joists in my climate? Could I stuff the cavity with insulation, (which I have a lot of) without attempting to block air and vapor? Should I use a vapor barrier in the floor? On the outside of the insulated space or the inside?

Housecat,

Malcolm Taylor's advice in Comment #33 below is excellent. Briefly:

1. No, you don't want to encourage air movement through your floor assembly. Air movement robs the assembly of heat and makes your subfloor and flooring cold.

2. You are mistaken in your assumption that "stuffing the cavity with batt insulation" will "prevent cold air from filtering into the building." Batt insulation is not an air barrier; it does little to slow down air flow. What you need is an air barrier. (Once you have an air barrier, the insulation is useful -- not to slow down air flow, but to provide R-value.) In your case, the best air barrier would be the exterior plywood (the plywood on the underside of the joists) -- but only if the plywood seams are taped with a high-quality European building tape. I hope there is enough access for you to get under the floor assembly to tape the plywood seams.

Thank you both for the advice; this clears up the uncertainty that I was having.

Now if it would only stop raining...

Housecat,

Neither building scientists or the BC Building Code would encourage air-movement in any assembly with the exception of purpose-built ventilation cavities on the outside of walls and roofs.

Old houses lasted because they relied on the heat from the interior keeping the wood dry. That worked because they had no insulation. The penalty was you had to throw money at them to keep them warm.

Insulated houses stay dry by limiting the moisture that can enter the walls to less than can escape. For most assemblies that means they need an air-barrier, and an interior vapour-retarder, in conjunction with a vapour-open exterior.

So what that means for your floor is:

- Yes you can simply fill the joist bays with batts, but you would get a much warmer floor if you had covered the underside of the joists with a layer of foam before applying the plywood.

-Pay attention to air-sealing. The batts are there for insulation, not to stop air. Ideally tape the joints on the plywood soffit, and seal penetrations in the subfloor.

- You don't need a separate vapour-barrier, the plywood subfloor is one.

Hi all,

I am building a round cabin kit in zone 7 in Maine. It is a pier foundation. The floor joists are 2x6 pt. My original plan, following lots of the advice on GBA was to install continuous foam on the underside of the joists, sheath that with taped plywood, and then fill the joist bays with cellulose.

For a variety of reasons, including the detail of how the joists are installed (radiating out from a central circle meaning irregular joist spacing), this approach is very labor intensive and would result in a good bit of waste of sheet goods, plus some install difficultly on the underside of the floor system.

My question is, putting aside the associated carbon for a moment, is there any performance based reason to not to do this job with closed cell spray foam installed from the underside of the subfloor down between the joist bays and covering the underside of the joists for thermal bridging?

I would greatly appreciate your thoughts.

Thanks!

jlipowitz,

You sometimes see a similar thing in parking garages of c0ncrete buildings. Not a performance based reason, but the problem I see is that it will be difficult to cover the underside, which may be necessary both for fire-protection and to keep out pests.

Have you considered adding the continuous foam to the top side of the floor system?

Hi Malcolm,

Thanks for the suggestion. The effect on floor and cieling heights woudn't work out if we added the foam to the top side. If we were to go with the spray foam underneath and we were going to sheath it with plywood, would we need to completely fill the joist bays with the spray foam? Given the high r-value, I'm wondering if we could come down 4 inches with the spray foam, and add a strip of sprayfoam on the side and underside of the joist for thermal bridging, and then cap it with the plywood. That would effectively create a 1 1/2" airgap at the bottom of the installation between the plywood sheathing and where the foam begins in the joist bay. Any issue with that?

Thanks,

Josh

Josh

Josh,

Practically I can't see how you could consistently add enough spray foam to the sides and bottom of each joist such that a) they were effectively thermally broken, and b) the spray foam was flat en0ugh to add plywood to.

If you are set on using spray foam, I would strap the joists with 2"x2"s, foam right to the underside of them, and sheath that. My own preference would still be to add foam board to the underside, and use batt insulation in the cavity.

Hoping to reopen this thread with a couple of questions. I have two sections of an older house in Maine (Zone 6A) that are exposed from below. One section 8 x 14 with 2x8 joists suspended from 6x6 rim beams, and another slightly larger section with 2x10 joists. Questions:

1. Are the foam to fluffy stuff rations the same or different from walls and ceilings?

2. It seems like Zip R under joists would provide both a thermal break and air barrier, correct?

3. In the Fine Home Building article referenced in the original post, a case is made for using foam board below the floor, and sandwiching fluffy stuff between a second layer of foam under the joists. I was considering this for the 2x8 section to increase r value but wasn't sure it was worth the extra work cutting and cobbling foam on my back under the house. This sandwich is not referenced anywhere else in the thread--is it even still considered a good idea?

Thanks for any and all input as always,

Brad

1. There are different ratios for foam-to-fluffy between roofs and walls. In climate zone 6, which includes most of Maine, we need at least 50% of the R-value in the roof assembly to be impermeable--i.e., foam. In walls with at least a class 3 vapor retarder on the interior, we need about 1/3 of the R-value to be in the foam layer. In floors, vapor drive is much different, and the ratios don't really matter.

2. Yes, I think that's an ideal location for Zip-R.

3. I have never seen that done and I don't see the point. If you're trying to increase the overall R-value, I would probably opt for more foam below the joists. The effort to cut-and-cobble foam between joists is significant for the modest increase in R/in. (Polyiso, including what is used for Zip-R, will age to around R-5.6/in, and performs worse the colder it is. Vs. fluffy insulation that performs better the colder it is.)

Thanks Mike. I will go with R 12 Zip below and as much Rockwool as I can cram in the space above!

Log in or become a member to post a comment.

Sign up Log in