In 2008, Hurricane Ike rolled over the Texas Gulf Coast destroying over 90% of buildings in Gilchrist, Texas. Ten years later, Hurricane Michael’s route through the Caribbean and over Florida left behind wide-spread devastation estimated at over 25 billion dollars. The two homes pictured below were built to survive these catastrophic Category 5 hurricanes, something that clearly can’t be said for many of their neighbors.

While both homes included materials and techniques in their construction that might have been above and beyond standard codes, they also used readily available products such as hurricane-rated impact windows and doors intended to meet the more stringent requirements in their locations.

Glass thickness and interlayers

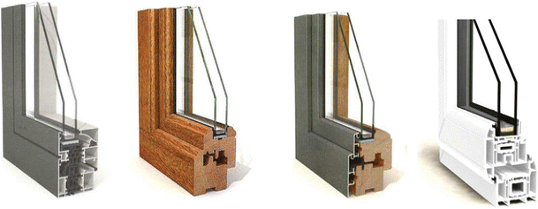

Impact-resistant windows typically have a structurally reinforced frame and sash, heavy-duty hardware, and laminated glass. Given all laminated glass—and tempered glass—is impact-resistant to a greater or lesser degree, what makes the glass installed in windows intended to meet hurricane-resistant standards special?

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

As mentioned in Part 1 of this series, the interlayers used in laminated glass can vary in thickness depending on application; .030 in. for safety, .060 in. for security, and .090 in. for impact resistance is a broad generalization, but it is a reasonable range to use as a guide.

Hurricane-impact windows typically have laminated glass constructed using interlayers made with either polyvinyl butyral (PVB) at .090 in. or SentryGlas (SG) at .095 in. There are laminated glass options in both thicker and thinner variations, plus a few options using interlayer materials other than PVB or SG, but they are niche products that won’t be addressed here.

While the interlayer thickness required for impact laminated glass is fairly consistent at .090 in., the glass used can vary from 2mm to 6mm or even thicker, depending on location and application. (While the interlayer is most often presented as decimal inch, glass…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

4 Comments

In the first picture of the Andersen window, why have the impact resistant glass on the inside so that you are guaranteed to break the outer glass(non-impact rated) when things start to fly? Is there something I am overlooking?

User...309,

Our code lays out several situations where safety glass is required on the interior face of windows. On stair landings, if the glazing extends down close to the floor, in showers, etc. Those quite common situations are probably what the photo shows.

There are several reasons for placing the laminated impact unit to the inside, and this is something that I do address more in depth in laminated glass, part 2, but probably the best reason is that if the glass does take an impact hard enough to break both lites it's much safer if the broken glass from the non-laminated layer stays outside. Installing the laminated unit inboard does that.

Greg,

I should have just waited for you to reply...

Log in or become a member to post a comment.

Sign up Log in