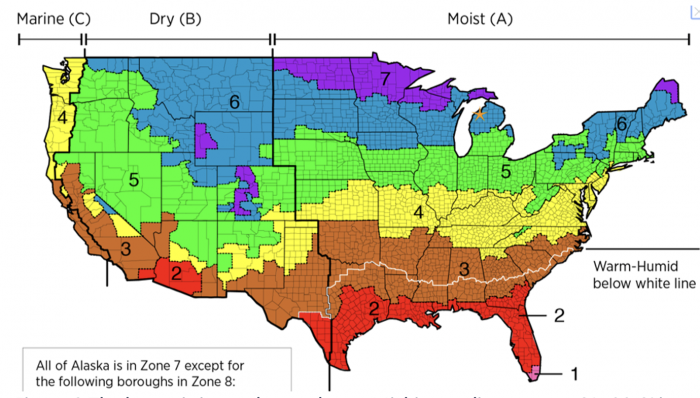

After spending countless hours researching information from Green Building Advisor (GBA), Building Science Corp, Energy Vanguard and more, I undertook a mostly DIY, all-electric new-build project in Northwest Lower Michigan (Climate zone 6A, Cold). I’ll review overarching strategies and concepts and include real-world data, details, and general experiences gained over three full years since moving in.

When designing our home I drew much inspiration from the Pretty Good House, PassivHaus and Net-Zero Energy programs. These programs generally boil down to first minimizing the building energy loads, then meeting those loads as efficiently as possible. The former focuses on the building envelope, while the latter relates to systems: HVAC, water heating, and cooking.

The building envelope

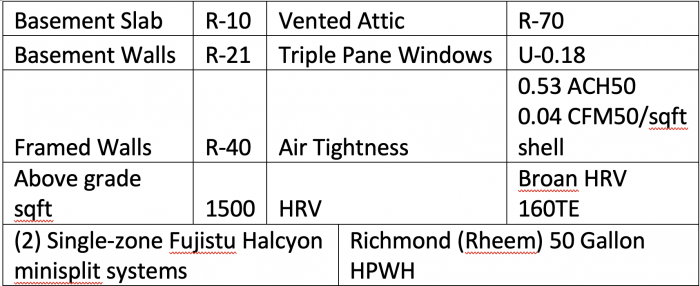

Thoughtful attention to the building envelope eliminates a portion of heating and cooling energy from ever needing to be used. It is often accomplished with continuous exterior rigid insulation, better performing windows, shading strategies, and improved airtightness when compared to code minimums. Simplifying massing by reducing ridgelines, corners, bump-outs and similar transitions greatly facilitates successful application of these strategies.

I designed the house with simplicity in mind; the character is found more in the finishes and less in the massing (a rectangle with a two ridge-line roof). Framing is 2×6 with a single top plate and floor/ceiling joists aligned with the studs. I installed 5 in. of exterior insulation over the wall sheathing—perhaps excessive, but there was a local source of factory-second polyiso.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

I framed the ceiling with I-joists and installed structural decking over top and sealed this (the attic floor) to the wall sheathing. This approach simplified air-sealing and provided a nice platform for installing the standard roof trusses, which sit on 20-in.-tall pony walls.

The I-joists provide a service cavity and eliminated about 60 building components including top plates, junction boxes, and myriad holes for Romex electrical cable that would have otherwise required careful air-sealing. There are two small penetrations for Romex servicing exterior lights and one large one for the plumbing vent; all are well-sealed. Access to the attic is through a gable end and there is nothing up there except loose-fill cellulose.

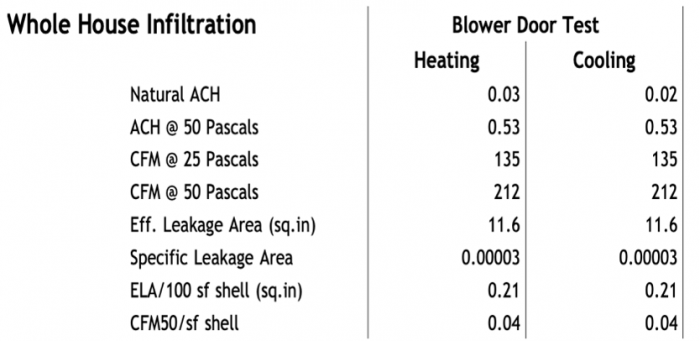

Airtightness

As homes get tighter and tighter, make-up air should be considered for clothes dryers (if not using a ventless dryer), kitchen range hoods, and even bath fans. Otherwise, make-up air will be pulled from unexpected sources and the fans or appliances likely will not be able to provide their rated CFM. We found this out the hard way, although it has been pointed out here and in Building Science Corp articles.

We have a sealed sump pit that’s connected to the main plumbing vent. When the range hood or the dryer was running, that plumbing vent effectively became a stinky make-up air source. I sealed the sump lid and rubber gaskets around the PVC pipe with silicone to stop the back drafting of sewer gases.

Looking at the HERS report, the blower door was pulling only 212 CFM at 50Pa—this is a tight house. For reference, the kitchen range hood is rated at 399 CFM on max and likely 100-250 CFM at the intermediate settings. A dryer is rated around 200 CFM and although none are installed here, bath fans are rated around 50-150 CFM.

Without a makeup air source, these systems are likely unable to provide their rated CFM.

I installed a makeup air system consisting of a duct and motorized damper. The damper is controlled by a differential pressure sensor that monitors the difference between the indoor and outdoor pressure. When the indoor pressure drops, a sign that either the range hood or dryer is running, the damper opens to provide make up air.

Heating and cooling

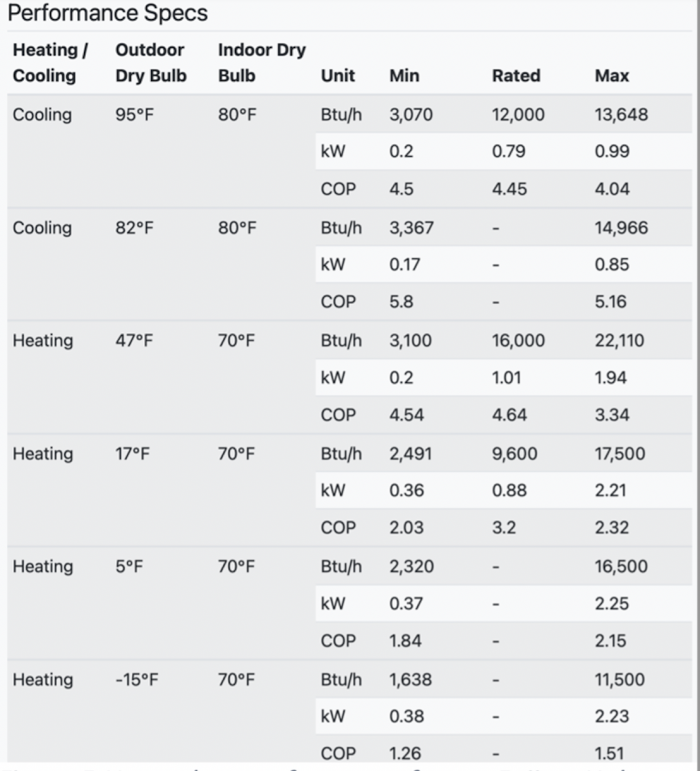

To meet the remaining heating and cooling loads I chose to use heat pumps, which can provide both heating and cooling from the same equipment. Many cold-climate systems can operate down to about -15ºF and some can continue operating at even lower temperatures (even very cold air contains heat that heat pumps are able to capture and pump inside). With thoughtful attention to the envelope, a small minisplit heat pump system can meet the bulk, if not all, of the heating needs in Climate Zone 6 and most in Climate Zone 7.

Furthermore, these systems can meet those loads very efficiently. Depending on the model, nameplate efficiencies (coefficient of performance or COP) over 300% at 17ºF and over 400% at 47ºF are possible, whereas electric resistance and fossil fuel heating appliances peak in the 90-100% range. While real-world efficiencies will vary, heat pumps can still average over 200% on a net annual basis even in very cold climates. This level of performance often provides lower heating bills compared to propane and heating oil and can sometimes compete with natural gas, especially in regions with low electricity rates.

Quick aside: I promise we are not breaking the laws of thermodynamics with efficiencies > 100%! Instead, this is a different definition of efficiency. The fundamental definition of efficiency is energy out divided by energy in. In this case, we are only interested in the input energy that we must pay for, i.e. the electricity, and we ignore the free energy harvested from the air. Another way of looking at it is: for every unit of energy paid for with the performance specs above, over three units of heating are provided at the 17ºF rated conditions.

My home is heated with two single-zone Fujitsu Halcyon cold climate mini-split heat pump systems (AOU12RLS3Y and AOU12RLS3H). Both indoor units are the ductless wall-hung types: the one in the living room serves the kitchen, dining, and entry area; the other in the hallway serves the three bedrooms and two bathrooms.

The wall unit works perfectly for the living area side of the home and maintains a consistent temperature. At the sleeping end of the home, there is a bit more variance, but within our tolerance. They kept the house warm all winter long, even when temps dipped into the negatives or lingered in the single digits.

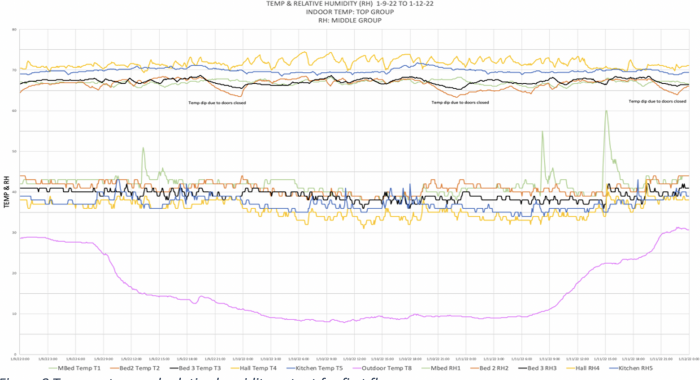

If the bedroom doors are closed, the temperatures can be a bit cooler than the hallway. For us, this is ok because we don’t spend much time in the bedrooms besides sleeping and we leave our doors cracked at night. Plus, we like cooler temps for sleeping. The following graph helps quantify this experience.

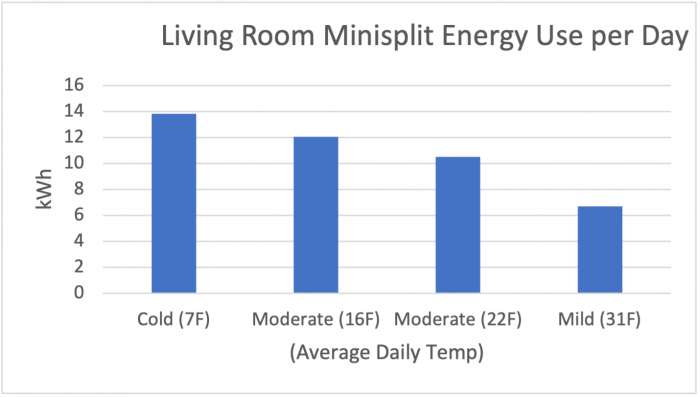

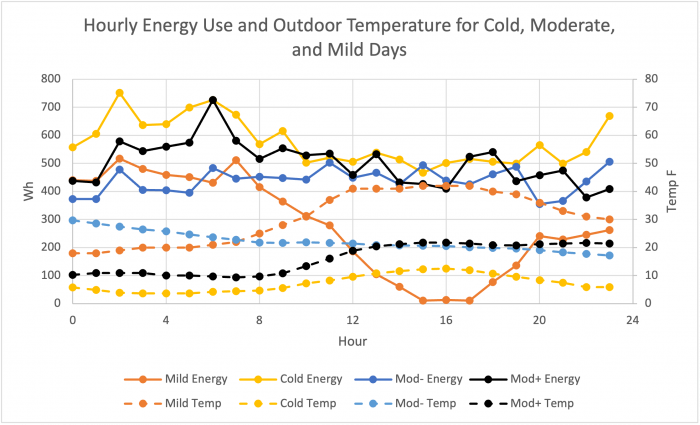

I installed a data logger on the living room minsiplit system to monitor its energy use. In the following charts we can see the daily and hourly energy use across a cold day (7º F avg), two moderate days where it’s warming up or cooling down (16º F and 22º F avg), and a mild day (31º F avg). We can expect a reasonable correlation of energy use vs. average outdoor temperature, but other factors such as solar or internal gains come into play. On the mild day we used about 7 kWh while on the cold day we used about 14 kWh. Looking at the hourly chart, we can see the unit went into standby from 3-5pm on the mild day when temperatures were around 40º F.

Ventilation

Adequate ventilation is often underappreciated, but it is essential for good indoor air quality and even more important when tightening up buildings, particularly in colder climates where windows are typically closed all winter. There are a few options for ventilation, but for a tight house in a cold climate a balanced system with heat/energy recovery is the optimal approach.

I installed a Broan 160TE HRV, supplying fresh air to the bedrooms, living spaces, and basement and exhausting from bathrooms, kitchen, and basement. There are boost switches in the bathrooms and no bath fans.

Additionally, the kitchen range hood needs to exhaust to the outdoors. I tried a recirculating range hood with a filter in a tight house once because I wanted to avoid that additional hole in the envelope. However, it lived up to its name and just recirculated the odors, smoke, and water vapor and it took a long time for them to dissipate. Another one of those things pointed out on GBA and by Building Science Corp.

Domestic hot water (DHW)

Heat pumps are the answer when it comes to hot water as well. There are two options for heat pump water heaters (HPWHs): split systems that have both an outdoor compressor and indoor storage tank, or unitary systems where the compressor is located on top of the storage tank. The unitary system is best placed indoors in cold climates since performance of the system is reduced with cooler temperatures. At around 40ºF, most systems will switch to pure electric-resistance mode, eliminating any energy efficiency benefits of the heat pump.

When placed indoors, HPWHs cool the space. The cooling effect is not ideal in the winter—okay, in the shoulder months—and usually not an issue in the summer. For this reason, the ideal location for a unitary HPWH is often a basement, large utility room, or insulated garage. Otherwise, locating it in any area that’s conditioned by a heat pump can be a good solution since the heat pump can efficiently make up the lost heat captured by the HPWH. These units are louder than a standard electric-resistance unit, and sound attenuation may need to be considered depending on location.

In cold climates, the unitary heaters should not be fully or partially ducted to the exterior due to the performance penalty with colder temperatures. Exhaust-only ducting is not recommended as these systems have large CFM draws and long runtimes, resulting in a non-trivial energy penalty for reconditioning the make-up air.

Some of the systems allow for scheduling of operation and can be set to operate when away at work or sleeping if noise is an issue, for example. Coupling these control strategies with a higher setpoint and larger storage tank can potentially mitigate most noise or cooling issues. Alternatively, a split system avoids these concerns but costs more.

In my house, we started with a standard 50-gal. electric-resistance water heater. I installed a recirculation loop that is both occupancy and temperature controlled. Occupancy sensors are at each point of use and a temp sensor is located on the loop near the kitchen supply—the farthest point. Before switching to a 50-gal. HPWH (Richmond 10E50-HP4D), we were using about 11 kWh/day for hot water.

After installing the HPWH, we started out in energy-saver mode and averaged about 3.5 kWh/day in associated energy use. This lined up with the anticipated 2/3 reduction in energy use.

However, we were frequently running out of hot water. I observed the upper and lower tank temperatures drifting quite low before the unit would kick on. The recirculation loop was likely exacerbating the problem—the manual stated recirculation was not recommended when operating in energy-saver mode.

We switched to high-demand mode, which involves more frequent operation of electric-resistance elements. I expected energy use to at least double, but much to my surprise, it only increased by about 60% to 5.5 kWh/day, and we have yet to unexpectedly run out of hot water.

Using a free app on my phone I measured the sound level during compressor operation at around 60 dba from 3 ft. away—it sounds like a window air conditioner. The unit is in the unfinished side of the basement that serves as a storage and utility area, so the noise really isn’t an issue. We only hear it running when we are in the room, but if it was near a bedroom or other living space, I would certainly implement sound mitigation strategies.

Cooking

When shifting from gas to electric for cooking, the two cooktop options are standard electric or magnetic induction (the only electric oven option is standard electric resistance). Induction systems use an electric coil below the stovetop surface to create a magnetic field. The magnetic field induces a small current within the highly resistive pan causing it to heat up. This process ends up being more efficient, responsive, and safer than its standard counterpart. Most of the energy is transferred directly to the pan, the magnetic field is highly controllable and rapidly responsive, and there is no direct heating of the stove surface—it will only get as hot as the pan.

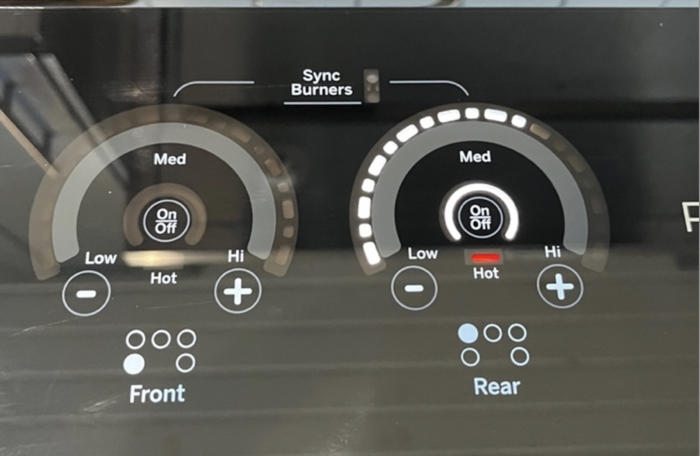

My wife and I enjoy cooking and we were dreading the shift from gas to induction, but it ended up not being that big of a deal. We installed a GE PHS930SLSS induction range. We burned our first few meals but quickly figured things out. Some things we like:

- There’s a high degree of temperature control, 19 settings, and rapid response.

- Controls are easy to use on this model. Touch on/off, then either touch the control at the appropriate level or use the +/- buttons.

- Water boils very quickly.

- The stovetop doesn’t get that hot, which keeps the stovetop cleaner and young chefs safer.

- We can’t tell the difference between gas-cooked or induction-cooked food.

Some considerations:

- We had to sacrifice some of our pots and pans since they were not compatible with induction.

- There can be some buzzing and clicking, which we notice more with lighter weight pans or hybrid type pans (non-metallic with an induction compatible base).

- A few of those types of pans aren’t always detected, even though they are induction compatible. The control flashes when it can’t detect a pan.

- Pans larger than the ‘burner’ will have cool spot in areas not directly over it.

All in all, we are quite happy with the induction cooktop.

Overall energy use

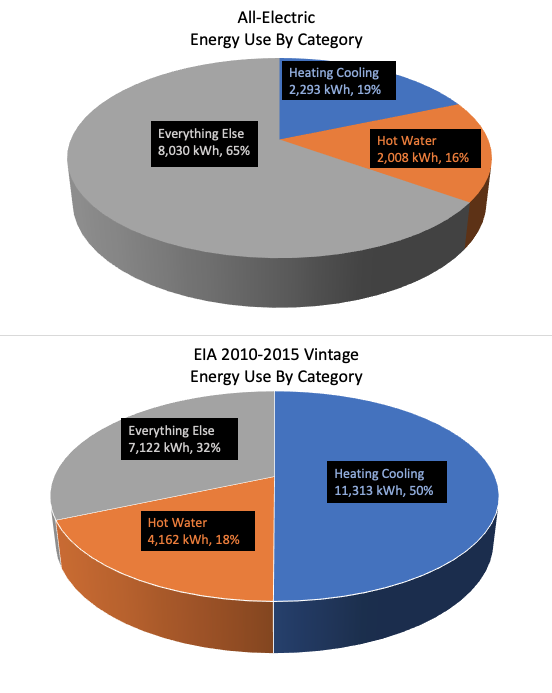

For the 2021 calendar year, we used 12,330 kWh of electricity. A ballpark analysis breaks this down further as 20% (2.3k kWh) for heating and cooling, 15% (2k kWh) for hot water, and 65% (8k kWh) for everything else.

The Energy Information Administration (EIA) data on homes built between 2010 and 2015 in the Midwest showed a breakdown of about 50% (11.3 kWh) for heating and cooling, 18% (4.2 kWh) for hot water, and 32% (7.1 kWh) for everything else—a total use of 22,600 kWh. Compared to that data, our newer high-performance home uses 45% less energy overall: 80% less heating and cooling, 45% less hot water, and 13% more plug loads.

These EIA numbers do not control for building size or number of occupants which are more influential than building vintage when it comes to hot water use and the everything else category. However, as imperfect as the comparison is, it illustrates how the energy use of a building changes as one enters the high-performance realm.

Final thoughts

We are entering our fourth year in an all-electric home, and we don’t feel like we are missing out on anything without gas-fired equipment—the house is warm, the water is hot, and the food tastes great. Our energy use and utility costs have been low, even though we are using what is often the most expensive energy option. It’s made possible through the high-performance approach to design: First, substantially reduce the loads through a thoughtful envelope design, then meet those loads as efficiently as possible with heat pumps.

At a grander scale, our design choices have prepared the house for a clean energy future. We can progress along with the grid or maybe leap ahead with a PV system; our utility offers a community solar panel purchase option as well. Ultimately, I can confidently say all-electric homes can work in cold climates.

_________________________________________________________________________

Nathan Russell is an Energy Engineer Manager at Beyond Efficiency. He draws on his first-hand construction experience and technical background to facilitate the adoption of high-performance buildings and practices. Images courtesy of author, except where noted.

29 Comments

Congratulations! This is a fine example of rational house design - now if we could only

educate the majority of the population to the point that housing like this became the

worshiped ideal rather than the transitory aesthetic fads that have historically driven

house sales. This, of course, should be an example of what everyone should expect in

a "forever home".

It makes one wonder - does it take an engineer to desire and live in sensible housing?

Sorry, I realize this sounds like a rant - when I actually only intended praise and

encouragement.

Yes. Congratulations Nathan. Thank you for sharing a well thought out and well executed build. A question: I am also in Zone 6 but in a different state. I looked at the summer and shoulder season humidity levels in your areas, and they’re similar to mine. Have you had any need for dehumidification in the summer, especially with the HRV instead of ERV core and a presumably similar low cooling load and low dehumidification capacity with those mini splits?

Thank you. There were times when we opened windows and indoor RH would climb, but when the ac was operating with windows closed, we never felt the need for additional dehumidification. I would look at the T & RH display throughout the day and remember seeing T & RH around 74F and 60%.

Thanks for the excellent article.

A couple of questions about the comparisons you draw:

> The Energy Information Administration (EIA) data on homes built between 2010 and 2015 in the Midwest showed a breakdown of about 50% (11.3 kWh) for heating and cooling, 18% (4.2 kWh) for hot water, and 32% (7.1 kWh) for everything else—a total use of 22,600 kWh. Compared to that data, our newer high-performance home uses 45% less energy overall: 80% less heating and cooling, 45% less hot water, and 13% more plug loads.

- You don't mention the # of occupants in the house. Is it the same as the average house, 3.5ish? This has an significant effect on water heating and plug loads.

- You don't mention the house size. It seems to be far more sensibly sized than the average home built between 2010 and 2015, and that has a big effect on energy consumption also.

I agree and indicated that vintage isn’t the best factor for evaluating plug and DHW loads and noted that # of occupants and size are more influential. This is an imperfect comparison, and my intent was to show the change in the distribution of energy use. I think the numbers may shift when controlling for more variables (climate zone [Midwest covers 3 zones], # of occupants, size, etc), but I believe we would still observe a significant difference with the distribution of energy use. We are a family of four and house size is 1500 sqft above grade, but 3,000 sqft of conditioned space with the basement.

Thanks for sharing more details. Looks like the 1500sqft below grade adds very little to your energy consumption. I suppose Hobbits are on to something by living underground!

In the interest of increasing the dataset here, I'll provide my own equivalent data:

Zone 3 (but in a heating-dominated micro-climate of coastal CA)

1600 sqft

4 occupants

Fully Electric (Space, Water Heating, Cooking, Laundry)

Annual House Electricity Usage: ~7500 kWh

50% of electricity usage offset with PV

Annual House Utility Electricity Cost: ~$940 (at average price of $.25/kWh)

It would be a really interesting exercise to calculate the probable amount you save

per month compared to the average house of similar size built only to code in your

area and then assume you put that amount in into something like a high-rate ETF

every month for say 25 years.

My guess (without running any figures) is that the total saved might be a substantial

portion of the construction cost of the house - it would, at the least, provide an educated

guess as to the economic benefit of building and living in a really well-designed energy

efficient structure for most of a working lifetime.

if you are going to do that, you need to factor in the extra spent up front and calculate a break even point first.

".... economic benefit of building and living in a really well-designed energy efficient structure"

For me, it is not just about the economics. I was listening to BS and Beer and they spoke about how there is always a focus on the incremental cost to build highly insulated, air tight homes. They focused in on the question people very often ask: "How much more will it cost in % in relation to the overall build cost?"

BS and Beer went on to highlight that the question of extra cost rarely - if ever - comes up when it comes to talking about high end finishes, high end brand appliances, high end plumbing fixtures, high end lighting. I would add to that the cost to buy land with better views or maybe installing things like pools, saunas, or hot tubs. Installing a pool can apparently limit your resale audience and potentially limit the resale price... but people do it every single day because of personal preference (negative ROI).

We have lived in hard-to-heat drafty homes. My family does not want that anymore. I took great pleasure in designing our energy efficient structure and watched the building process with interest. We agreed up front that the envelope was the primary focus and everything else was secondary. We don't know the cost of energy next year, or in 20 years. That is one very important reason why ROI calculations would not factor in to my decision making. For all we know, in 20 years from now there could be amazing technological advances with virtually zero energy costs that bring with it zero emissions. In such a scenario, people would argue that building energy efficient structures was all be for nothing.

We are all different and we all look at these projects from our own personal perspective. What is important to one person will not be as important to the other - and it should be that way. We should all celebrate the variety of perspectives because I believe that there is no right or wrong.

As a last point, I am shifting my own focus towards other aspects of building, such as engineering resiliance to mitigate the impact of major weather events. If high winds tear off my R90 roof and rain destroys my R40 walls in a major storm, the ROI for energy efficiency is going to be really terrible for my own build.

Totally agree. For us it just makes sense to construct an energy efficient home. It's the right thing to do. As you said, it's all about the envelope. Since we're building in a forest we also took measures to make our house fire-resistant by using siding and roofing material that won't burn or melt. Many of the tree that were cleared went to a local saw-mill and will be used for door and window framing and the nicer pieces for the kitchen island top.

BEopt software, which is pretty fun to screw around with, has tools to compare present values of different building assemblies.

https://www.nrel.gov/buildings/beopt.html

A question on the framing of the building;

any particular reason you built the 20" attic wall instead of using a truss with a 20" energy heel?

If I am remembering correctly, it was due to the cost premium for raised heel trusses as labor was my own to build the walls. There is a tradeoff, though, as they would simplify the process.

Very interested In the applicability of these concepts to a home built in 1978, Duluth, MN so Zone 7. This rancher with a fully finished lower level is 1500 sf per level and is on an east facing slope. I get winds off Lake Superior and my windows are not yet triple panes. But I bought it for the view.

Right now I need advice or referrals to a GC who can install a ventilation system with heat exchanger and makeup intake. Would like to integrate a 24-36 Kbtu Mitsubishi HE heat pump in this unit. I already have another one providing good service but having a second, smaller one would give me whole house coverage in hi cooling and heating cycles while running the smaller one through the ventilation system would have higher operating efficiency during moderate periods.

Anybody with a name or two, I’d appreciate it. My cell is 507 703 1370.

Thanks,

Rob Goodell

I very much enjoyed reading your thought process. My wife & I have just started building an off-grid passive home in North Bay, ON, Canada, 4 hours North of Toronto and spent a lot of time tuning our home for energy efficiencies. All our electrical power comes from solar and/or wind. We're building using pre-fab panels that are 9.25" thick and R50 (before finishing added) . The roof is also pre-fab panels over trusses and are R85+. The panels have no thermal bridging and with proper installation are very tight. Our windows are from a company in Edmonton, Alberta and are R14 for the fixed windows (they are 3.5" thick) and R11 for the casements. Our total daily energy usage is between 4.5 - 8.5 kWh depending upon the time of year and what we're doing. The home is 'earth bound' so heat collected under the house during the summer months and lost during the winter maintains a fairly constant temperature year round (at least that's the theory). Since our heating loads are so low, our domestic hot water and space heating are combined using 2 tanks. One tank is heated by solar and wood stove and the other is a heat pump water heater that only operates when there's excess power from solar or wind. All our calculations show that things should work, but it's really one big experiment. We are doing so many things that are outside the norm that our biggest challenge has been getting a building permit. We start building spring 2023.

Doug906 - which company in Edmonton, Alberta has these windows? I am in Central Canada and would love to find out more.

What part of Central Canada?

The company is Litezone (litezone.ca). They have been great to work with. For fixed windows you can order direct from them. For operational windows you deal with one of the company they list that can work with the larger window thickness. We have a combination of fixed and casement windows. We're dealing with Duxton Windows in Winnipeg for the casements.

I am in Eastern Ontario near Ottawa and will be looking litezone.ca for future requirements!

Nathan, great project! Thank you for sharing.

I’m in the middle of a high performance renovation of a home in zone 6 (VT). I’m intrigued by your make up air system. Using a differential pressure sensor vs. some kind of relay sounds like a good option, especially to solve potential issues with a clothes dryer, etc vs just activating on a relay with the kitchen vent.

Can you share specific details about the equipment you used? Did it require any tuning / commissioning to make it work they way you want it to? Have you experienced any issues with it activating (or not) at unexpected times?

Thanks

120-24V transformer, 0.05-12" W.C. (Cleveland controls AFS-22-112) differential pressure sensor, and Honeywell EARD6TZ motorized damper. The 6" duct and hood was the largest size that fit within the bellyband wrapping around the house and I didn't want to touch the siding. If I had planned ahead for this system I would have increased to an 8" duct and used a trim block. I ran the outside probe tubing through the duct, then poked out the side of the hood for the reference pressure. Condensation will form inside the tubing. One winter the tubing froze and disabled the system.

With the simple controls, the damper cycles when the dryer runs or the range hood is on its lowest of three speeds. When the range hood is on speed 2, or the dryer and range hood at speed 1 are operating simultaneously, then the damper stays open. I have not revisited the setting on the pressure sensor and maybe it's as simple as decreasing the differential pressure to keep the damper from cycling. If I did it again, I would consider a more sophisticated system that could modulate the damper. Or, maybe adding a timer relay, setting at 5-10 minutes, is adequate.

This is a fantastic article. I'm thoroughly impressed by the author's science based approach and attention to detail and, frankly, in awe of the people who are building projects like these. We just took a visit to Traverse City, MI and would have loved to stop by for a tour! That said, we have a parcel of land in a Zone 7 area in CO (8,700 ft elevation and frequent below zero F throughout the winter) that I dream of building such a project on. Questions as follows:

* Would a similar building methodology work for my climate? Seems we are pushing the limits of what heat pumps are capable of here in the mountains.. The modern standard here seems to be code based framing, insulation (R25 & R40) and gas fired boilers tied to radiant, in-floor heat.

* I've also poured through untold hours of reading and research here and elsewhere to educate myself on building and building science; but, I've never actually built a house and still consider myself an amateur enthusiast. In regard to our building plan, we've been stuck in the mud with recent materials and labor costs in our area, I hear people are paying over-booked homebuilders $350 to $500 per sq ft for standard construction (which the vast majority of the builders I've encountered here are limited to) and I'm assuming it would be on the high end for a green build. Just when I'm on the verge of giving up, I see an article like this that makes a smart, efficient, and economical build seem doable. I wonder if there are resources out there to help me determine what's realistically possible given my location and budget; or to guide someone like me through a similar build process that I would manage locally. Do these types of consultants exist and does anybody here have any names/contact info that I could start with? Any other suggestions?

I'll do it! My company has built and sold three all-electric, heated-with-a-minisplit Holladay houses (since someone else co-opted Pretty Good House) for under $250k in the past nine months--all of them in the Duluth, MN market, which is Climate Zone 7.

josh@sisubuilders.com

Check out this article about the Pretty Good House book, and the comments, where Martin Holladay and the authors discuss who came up with the name and concept.

https://www.greenbuildingadvisor.com/article/maine-authors-publish-pretty-good-house

The same is happening in my region (North Bay, ON, Zone 7) where there's a shortage of skilled people. The vast majority of homes being built are stick frame construction with a few ICF homes. We couldn't afford to build at $500+/sqft so I started looking at other methods that weren't as labour intensive. First looked at hemp blocks (justbiofiber.ca). Then looked at using Structure Insulated Panels (SIP) and finally settle on Insulated Composite Envelop (ICE) from GreenStone (www.gsbp.ca).

We went with ICE panels for a number of reasons;

- cost less then the other methods, especially when wood prices tripled

- panels are light so we could do the installation ourselves

- installation is straight forward, simple and very fast (ie. save on labour costs if hiring people to do the work)

- creates a very tight, well insulated envelope

We also hired a good certified passive design engineer who provided a wealth of knowledge. Since we were acting as the General Constructor and also doing a lot of the work ourselves our cost per sqft will be between $150-$200. We've also never built a house before and will hire the expertise when needed. For example, we found an electrician & plumbing willing to work with us while we do most of the work and they make sure it's was done correctly.

It will take us longer to build than if we hired a contractor, but we're saving a ton of money doing it ourselves.

To help with your recirculation loop issue you should look at the Smart Recirculation Control. https://www.smartrecirculationcontrol.com/ Their controls solve the problem of heat pump water heaters cooling off while the pump is running. Their controllers are demand driven via a flow meter installed at the water heater so you don't have to maintain motion sensors scattered around the house. Just go to any hot water fixture and draw hot water for 1 second and it will kick the pump on, run it until the loop is up to temperature and then turn the pump off. Instead of using an absolute temperature value that may never be achieved, their controller uses the difference between the temperature of the water leaving the water heater and the water returning on the loop to know when to turn the pump off. As heat pump water heaters require a certain differential between the water in their tank and the water coming in to the heat exchange before kicking on the heat pump, their controller can be configured to turn the pump off when the difference is less than that required by the heat pump water heater thus restoring high efficiency usage AND providing on demand hot water.

Davelopment - I appreciate the link to Smart Recirculation Control. We are about to buy our recirc pump so great timing!

I absolutely love the the ceiling with I-joists and structural decking over top - with it being sealed to the wall sheathing. They don't give these I-joist away but this just makes so much sense to me. We thought of doing this on our build but the municipal height restrictions in our area did not allow for it.

We have a tested air sealing of 0.13 ACH50. We needed a hood vent given how much we cook and the type of cooking we do. Unfortunately, we don't have a return air system. We are 100% electric so that hood vent will do what it can. Congrats on your project.

Thanks Nathan for sharing your experience. I am doing something very similar, also in Michigan. I am wondering if you wouldn't mind sharing your source for the SANCO2 heat pump water heater. I am having trouble sourcing any air to water heat pumps since the new refrigerant regs were announced. Any reservations about using CO2 as the refrigerant? It is relatively rare among heat pump manufacturers in the U.S.

I installed a unitary hpwh and didn't use the Sanco (Eco2). Small planet supply has them. I also noticed eco2 systems is based in MI and they have a where to buy link. I have no reservations about using CO2 systems. Good luck on your project.

Log in or create an account to post a comment.

Sign up Log in