Poor installation of insulation matters. Even in cases where you might think the R-value won’t be affected, it is. Eleven years ago this month, I wrote an article about one of the most important and misunderstood principles in building science. The article is titled “Flat or Lumpy: How Would You Like Your Insulation?” In it, I showed what happens to the R-value when a poor installation of insulation is particularly bad. The attic in question was supposed to be a uniform R-30 but instead got only R-10 over 50% of the area and the other half was R-50. It does not average to R-30. In fact, it averages to a mere R-17.

Having that big a disparity in the insulation distribution, however, isn’t the most realistic situation. More likely is that you’ll get a couple of inches less in some areas and a couple of inches more in other areas with blown or sprayed insulation. Or maybe the installers shorted you on the insulation in one part of the attic but did not make it up elsewhere. Let’s look at those scenarios today.

Right amount, poorly distributed

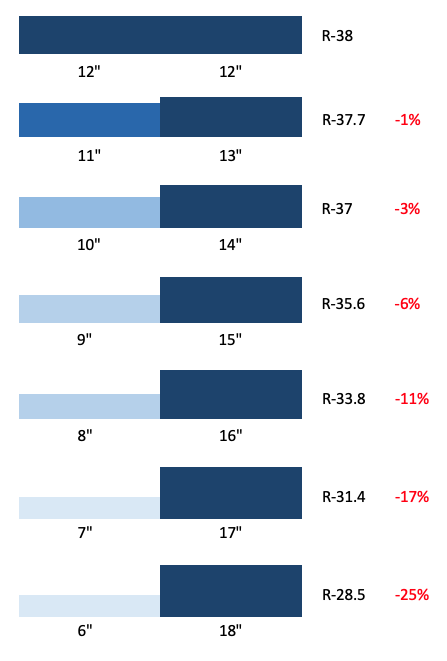

The graphic below shows what happens to the R-value when the installers put in the right amount of insulation. The top line shows perfect installation. The other six show various degrees of poor installation of insulation where half of the attic gets less than it’s supposed to and the other half gets more. On the right in black is the average R-value for each installation. On the right in red is the percent decrease in R-value from the target of R-38.

As you can see, when the insulation is shorted only an inch or two over half the attic and increased by that amount on the other side, the hit to R-value isn’t too bad (-1% and -3%). A 3-in. short on the left side knocks 6% off the R-value, and beyond that you’re in double digits, which I would find unacceptable.

I didn’t model all of the scenarios above when less than 50% of the attic has the poor distribution. But for 9 in. and 15 in. over half of the attic and 12 in. over the other half, the reduction in R-value is 3%. Compare that to 6% (line 4 above). For 6 in. and 18 in. over half the attic and 12 in. over the other half, the reduction is 14%. Compare that to 25% (line 7 above).

Wrong amount, poorly distributed

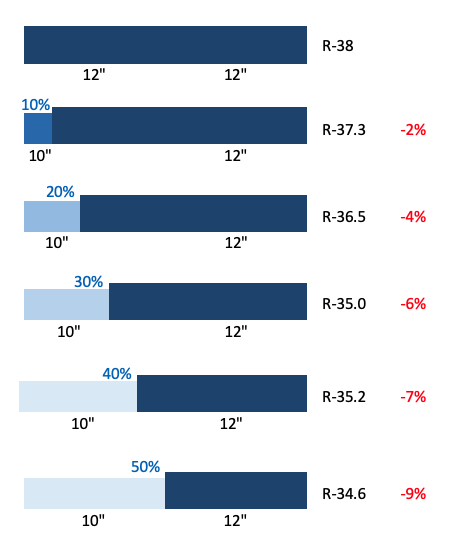

If the installers haven’t predetermined how much insulation material they’re going to install, another way poor installation of insulation can reduce R-value is by getting the correct amount over part of the attic and shorting the other part. The two graphics below show this scenario. In the first one, the shorted side gets 2 in. less insulation than it was supposed to. The top line shows perfect installation of a uniform 12 in. depth of insulation. The next five lines show the R-value and percent reduction in R-value when various portions of the attic are shorted those 2 in.

Getting 2 in. less insulation than you pay for over part of the attic knocks the R-value down only 2% if only 10% of the attic is affected. If, however, they short you those 2 in. over 50% of the attic, you’ve lost 9% of the R-value you paid for. That’s for a 2 in. short.

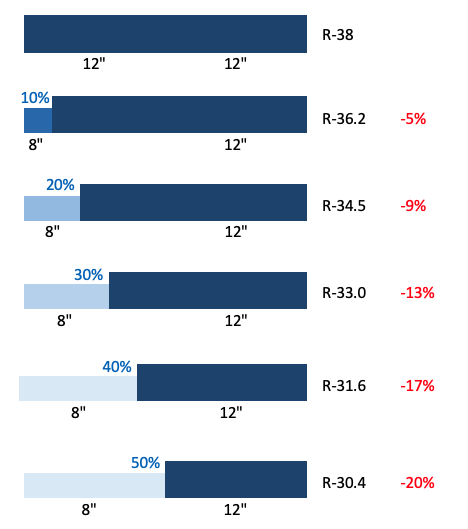

If the installers short you 4 in. over part of the attic, here are the resultant R-values and percent reductions in R-value:

As you would suspect, the 4 in. short becomes painful more quickly. Even 10% of the attic shorted 4 in. knocks your R-value down by 5%. With 20% of the attic insulation reduced by 4 in., the average R-value is down 9%.

Contracts and quality assurance

Understanding the tolerance of blown or sprayed insulation can help you get the insulation R-value you pay for. Insulation contractors usually specify the average thickness of insulation you’ll get. As you can see from the analysis here, average thickness isn’t good enough.

A better way to ensure you get what you’re paying for is to specify the average thickness of insulation as well as a minimum thickness. The tool that determines that for blown insulation is the depth marker, as shown above. Make sure your contractor puts in a lot of them. It’s easy for installers to pile it up to the required depth at the markers and install less between the markers. With more markers in the attic, it’s easier to see problems. With spray foam insulation, the tool is a depth gauge (shown below).

After the installers finish blowing or spraying the insulation, look at those markers or check the depth in enough places to know you’ve got enough insulation. Average depth alone is not a sufficient metric to determine the quality of installation of blown or sprayed insulation.

_________________________________________________________________________

Allison Bailes of Atlanta, Georgia, is a speaker, writer, building science consultant, and founder of Energy Vanguard. He is also the author of the Energy Vanguard Blog and is writing a book. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

6 Comments

This is the kind of analysis that should be done on all types of insulation in

various locations - I would really like to see something like this with regard

to cavities caused by settling in dense pack cellulose filled walls. Although,

I realize that obtaining enough valid data to be able to do the analysis would

be time consuming, expensive, and likely to provoke resistance to the study

from various groups who have an emotional and/or economic interest in

promoting the use of cellulose in walls.

>" I would really like to see something like this with regard to cavities caused by settling in dense pack cellulose filled walls."

The "...settling in dense pack cellulose..." is a bit of an oxymoron. Dense packed cellulose doesn't settle when packed to the appropriate density for the local climate.

Settling of cellulose in walls is function of mechanical creepage due to seasonal moisture cycling and density. At some density the creepage drops to zero due to the enhanced springiness of the densely packed fiber.

In New England 3.5lbs per cubic foot is the typical target density, but there is a lot of forgiveness in that number- 3lbs is usually enough. Even 2.8lbs is sufficient if done perfectly, in wall assemblies with adequate outward-drying details (such as rainscreen), and good air tightness and low vapor retardency to the interior to limit the amount moisture cycling in the cellulose.

Even the old school "2-hole method", can often hit densities high enough to mitigate against settling. About a decade ago while gutting the walls on a deep energy retrofit project I was involved with on an 1890s vintage plank sheathed balloon framed house with vinyl-siding over shingles the (then) 25-30 year old 2-hole method cellulose was perfect, with no apparent settling at the top. The vented space from the vinyl siding probably saved it. (That house got stripped to the plank sheathing, and ~4" of polyiso foam board was retrofitted, with a 3/4" rainscreen behind new fiber-cement siding, and against my lobbying for cellulose a full cavity fill of polyurethane was installed for improved air tightness. The place still looks pretty good inside & out.)

Around the same time frame I was called in to help out on a similar vintage & construction house with cedar shingle siding (no rainscreen) where the 2-hole method cellulose had settled 2-4 FEET on the shaded sunless north side of the house in only 8-10 years. Dense packing over the existing cellulose working from indoors on the top floor appears to have done the trick- the same people still live in that house and there have been no call-backs (and they even have my home phone number... :-) ) With no sun to help the shingles dry and no rainscreen the seasonal peak moisture levels were probably pretty high- too high for the lower density cellulose to stay put.

Is it really an oxymoron or perhaps urban myth? Or is it real? Until I see

a study involving a large number of homes (say a thousand or more)

which have been lived in for more than 5 years or so I will not accept

assertions that cellulose doesn't settle in walls - take a look at Thorsten

Chlupp's house in Fairbanks - he went to extremes to prevent any

settling, he blew it in at 4 lbs/sq.ft. , left the walls open

at the top with cellulose piled up a couple of feet over the open

wall cavities so it could fall in if any settling occurred and what happened?

A year later imaging with a thermal camera showed cavities in the

insulation in one wall - show me the study with thermal imaging of a

thousand homes ten years later with only a few failures and then I'll

believe! I admit that this single example isn't proof it's merely suspicious.

Thermal cameras are now common and inexpensive - no more assertions

and claims - lets see the study.

+1 on this. And, let's see the routine placement of high tech recording humidity probes into these walls, and see what profiles of temperature and humidity work, and fail...

This is such an issue. We inspect attics all the time and even though they know we're coming and will call them back, problems abound. Maybe we're just unlucky with subs up here, but it's honestly depressing. I can't imagine all the attics not getting checked, building inspectors aren't looking...

Love those charts, have you got a set for R-49 cellulose? They'd be really helpful making a judgement calls on some of the borderline cases that don't always get corrected. If not I might just have to make some up.

Andy, no, I don't have R-49 charts, but it wouldn't take long to do the calculations in the spreadsheet I set up and then modify the diagrams.

Log in or create an account to post a comment.

Sign up Log in