Kitchen ventilation is critical to having good indoor air quality in your home. Cooking, as the research shows, produces a lot of indoor air pollutants. The best way to deal with that is to have an exhaust ventilation system that removes those pollutants at the source. But when you exhaust air from an airtight house, you can induce some serious negative pressure. So what’s the solution? Do you need a range hood makeup air system?

As part of our residential HVAC design services at Energy Vanguard, we design makeup air systems for some of our clients. To do that properly, we’ve had to dig in on this topic to find the most appropriate solutions. Here’s a brief summary of what you need to know about range hood makeup air systems.

One in, one out

The first thing to know is that we’re talking about air. Yeah, Alex Meaney of Mean HVAC once said, “Air is squishy and hard to predict,” but there’s one thing about air that’s easy to predict. If you turn on an exhaust fan inside the house, it pulls air from the house and sends it outdoors. But that doesn’t mean the house has less air in it.

When a volume of air, a cubic foot for example, goes from inside to outside, a cubic foot will come in through the building enclosure to make up for that loss. If this happens in one minute, we call it a cfm, which stands for a cubic foot per minute. So in the building science world, we have this saying:

A cfm in equals a cfm out.

And that brings us to range hood capacity. How many cubic feet per minute does it move?

What size is your range hood?

First, let’s start by eliminating recirculating range hoods from this discussion. In general, it’s best to have a range hood that exhausts to the outdoors. Yes, Passive House designers like recirculating range hoods because they eliminate a penetration through the air barrier as well as eliminating the potential for negative pressure and the need for makeup air. But let’s save that discussion for another time.

If you’re putting in a standard range or cooktop, whether electric or gas, you don’t need a hood with a huge exhaust rate. Brett Singer, an indoor air quality researcher at Lawrence Berkeley National Lab, says 250 cfm should be enough. Of course, that depends on hood design, location, and capture efficiency. But just put the range against the wall and have a hood that covers the whole thing. With that setup, a 250 cfm range hood should suffice.

Going with a commercial range or cooktop? That’s usually where we see people installing the super-duper range hoods with capacities of 1000 cfm and higher. If you’re dead set on having a range hood with a huge capacity, you may need makeup air.

Do you really need makeup air?

In my article on airtight homes and makeup air, I mentioned that we get a lot of requests for range hood makeup air systems in our residential HVAC design projects. Then I wrote, “The first thing we try to do is convince them to put in a smaller hood so they don’t need makeup air.”

But when do you really need a makeup air system? The HVAC Applications Handbook from ASHRAE (2019 edition) says this:

The exhaust rate of residential hoods is generally low enough and natural infiltration sufficient to avoid the need for replacement air systems.

That may be true for a lot of houses but not for many of the ones with big range hoods and an airtightness level that meets current building codes. Here’s what the 2021 International Residential Code (IRC) says:

Where one or more gas, liquid, or solid fuel–burning appliance that is neither direct-vent nor uses a mechanical draft-venting system is located within a dwelling unit’s air barrier, each exhaust system capable of exhausting in excess of 400 cubic feet per minute (0.19 m3/s) shall be mechanically or passively provided with makeup air at a rate approximately equal to the exhaust air rate.

As you can see, it’s not simply a matter of range hood capacity. You also have to have combustion equipment that’s not isolated from the indoor air. Put a 2000 cfm range hood in an all-electric home, and you won’t be required to install a range hood makeup air system. That doesn’t mean you might not have problems; you just don’t have to put in makeup air.

Passive vs. active systems

Let’s say you decide you can’t give up that 1200 cfm range hood, and you plan for a makeup air system. You have to decide whether to go with a passive system or an active one.

Passive makeup air system. With this type of system, you have a duct connecting the kitchen to the outdoors. There’s nothing to move air from outdoors into the kitchen except the negative pressure created by the range hood. You don’t want that duct to be open all the time, though, so it needs a damper that opens when the range hood comes on and closes when it goes off.

Deciding where and how to let that passive makeup air into the kitchen is where things get really tricky. The best solution we’ve seen is this system designed by Ross Trethewey, PE from TE2 Engineering for NS Builders. This isn’t a cheap or easy way to do makeup air, but it does seem to work.

Active makeup air system. Rather than using negative pressure created by the range hood to move air, an active makeup air system has its own blower to move the air. This is our go-to method for clients who hire us to do makeup air. We use the Fantech makeup system because it includes a complete package and works well.

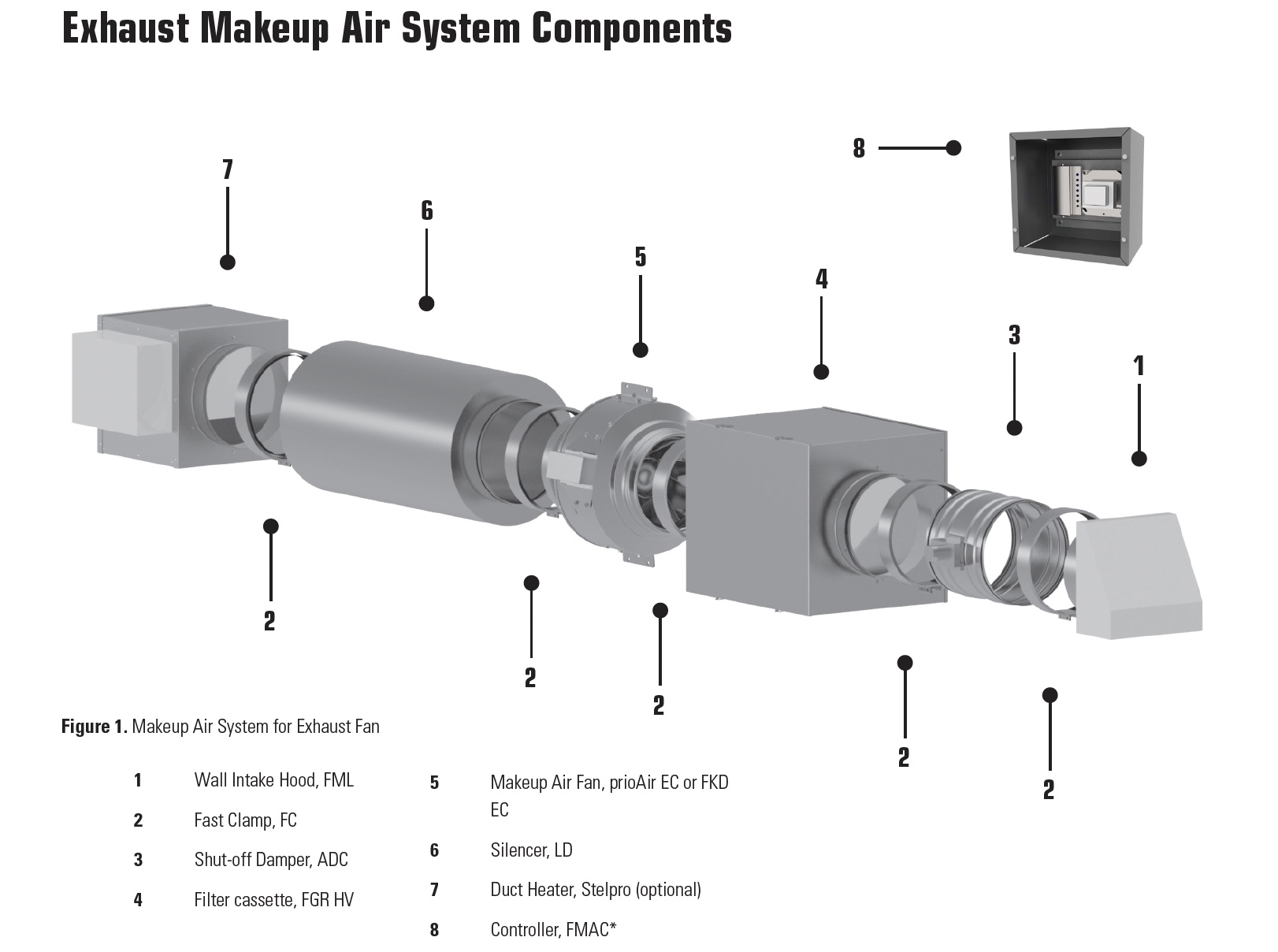

The diagram above shows the various components in the Fantech system. It includes the wall cap, filter, damper, blower, silencer, and an optional heater.

Where to locate makeup air intake vent

Once you’ve decided on what type of system, you need to figure out where to introduce the makeup air. Of course, the obvious location is the kitchen. Somewhere near the range hood, right? Here’s what the 2021 IRC says:

Kitchen exhaust makeup air shall be discharged into the same room in which the exhaust system is located or into rooms or duct systems that communicate through one or more permanent openings with the room in which such exhaust system is located.

So it doesn’t have to go into the kitchen. You could put it in the great room, living room, or some other room that’s open to the kitchen. Or dump it into the heating and cooling system so that it gets conditioned on its way in. One advantage of putting at least some of the makeup air outside the kitchen is that the kitchen then will be under negative pressure. That keeps kitchen pollutants from spreading out into the rest of the house.

Joe Lstiburek wrote a great article on this topic titled First Deal with the Manure and Then Don’t Suck. In it he discussed a method that we try to use in our makeup air system designs. Rather than putting all the makeup air into the kitchen, he puts about 60 percent of it into the kitchen. Then he puts the other 40 percent into a heating and cooling system to be sent to rooms connected to the kitchen.

Other things to consider

This isn’t an All About Makeup Air article. I’m giving you the basics here, but there’s a lot more that goes into a good makeup air system design. One of the big considerations, for example, is whether or not to condition the makeup air. Having 5 °F (-15 °C) air blowing across your ankles isn’t so comfortable. Nor is having hot, humid air fill your kitchen.

Similarly, it’s a really good idea to filter the makeup air to keep outdoor air pollutants from degrading your indoor air quality. And of course, you need to plan for the best location of the makeup air intake. You don’t want it right next to the range hood exhaust, for example. Or the garage, dryer exhaust, or too near the ground.

Also, how will the makeup air system be activated? There are products that allow you to do it with a direct electrical connection, pressure sensors, or heat sensors. You’ve got to get this right because the makeup air needs to run simultaneously with the range hood.

So there you go. Once you’ve digested all this, you should know enough to be dangerous. Or at least what to look for in a makeup air system. But the big thing I hope you take away from this is that you should just stick with a smaller range hood.

_______________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to the Energy Vanguard newsletter and follow him on LinkedIn.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

61 Comments

Is the T2E solution really working? The thumbnail of the video on this page shows what they actually wanted- the air going all the way down to the burners before coming back up. But why would the air want to do that when the exhaust is right where it comes in? When they do the smoke test to prove that it works, the smoke doesn't go down at all and instead gets directly sucked into the vent. So the system seems to be reducing the total ability of the exhaust hood to vent actual kitchen air. Smoke is not the same as actual air- its possible the actual airflow is similar to what is in the thumbnail. But it is also possible that a lot of the kitchen air is getting spread our rather than exhausted due to the interference.

Stick with what you are doing Allison!

Examples of systems on youtube where they prove the system is in balance can be seen from Home Performance (under the range): https://www.youtube.com/watch?v=bMkvCn1sGvk

or the Build Show (across the room): https://www.youtube.com/watch?v=rSIqKGsF2ZA

I asked Ross Trethewey (Principal at T2E) and he responded right away: "Working as designed, and the client loves it. I need to go back and shoot a video there because we have recieved too many questions about it!"

Thanks. There's so much capacity in that system that I have no doubt that it still roughly works.

The test that I think would provide the most useful information of these systems is an air quality test to figure out the rate of accumulation in the room of the real particulates emitted from the range when the exhaust is on. PM 2.5 and CO2 measurement? And test at different exhaust rates- the best solution would minimize overall energy usage (fan energy plus conditioning makeup air) for a given rate of pollution removal. The most practical solution would be effective at air quality but cost less to install, maintain, and operate (where operational costs are energy which varies on usage amount).

That would be a good test. It would likely have different results on every project, though.

This has come up before:

https://www.greenbuildingadvisor.com/question/kitchen-exhaust-and-make-up-air-all-in-one-hood

That type of MUA doesn't work, the only thing it does is exhaust the MUA without capturing any of the effluent from the stove.

TLDR,

Residential MUA feed should be run somewhere indirect into the kitchen away from the burners. Toe kick, behind stove, vents in soffit are all better options, simpler to install and are much more effective.

I'm laughing because I saw this article and thought "I feel like I've been angry about this before..." but couldn't quite put my finger on it, so thank you Akos for linking the post where my original ire was raised. :-)

It's a really good question and the thought experiment has consumed me for the last few minutes....

With any passive make-up air solution, I believe the make-up air supply duct(s) needs to be much larger than the duct for the powered exhaust run. So even with the make-up air coming from TE2's solution being drawn in at the front of the range hood it's not actually providing 100% of the 1200 cfm that's being exhausted. So where's the rest coming from - the kitchen. If I picture it in my mind there's a good deal of the 1200 cfm coming out at the front of the hood and then moving down and backward up through the exhaust, but because it doesn't match the exhaust cfm there's a general negative pressure gradient around the exhaust which draws air from all around the kitchen toward the exhaust. Plus you have the hot cooking surface creating lots of buoyant air supporting the drive toward the exhaust fan. So not perfect but not as bad as 1200cfm randomly being sucked into the house through your insulation (lol house filter).

In the end I agree that the illustration of the air moving down to the burners and then back up isn't probable, but I still think it's an effective solution. The arrows in the pretty picture may not match reality as Mike Guertin says but the system still works. He mentioned it matching commercial kitchen design, I'd be interested to hear more about what those look like.

Robert Bean wrote a wonderful article on this subject full of just terrible puns

"Well, it turns out (again) that the things we do on autopilot in our homes are coming back to bite us in the rump roast. It is now apparent to researchers that the smorgasbord of pollutants we sense as aromas, heat and moisture from indoor cooking are reaching concentration levels, which if measured outdoors would have environmental protection agencies shutting down kitchens and issuing fines.

Since there are no environmental protection regulations governing indoor residential kitchens, your lungs, skin and digestive systems have become the de facto filter for a soufflé of carbon monoxide, nitrogen dioxide, formaldehydes, volatile organic compounds, polycyclic aromatic hydrocarbons, fine and ultrafine particles and other pollutants associated with meal preparation."

https://www.hpacmag.com/features/the-essential-ingredients/

I’ve been ranting about kitchen ventilation for two years now. Upon hiring our architect, I immediately shared my requirements for kitchen exhaust and makeup air because I wanted her to make sure the design had space for the equipment as I also wanted the operation to be nearly silent. Many hours of research down the drain, it was one of many things the architect did not listen to. We don’t even have space for the inline blower in the open web joists because someone didn’t plan for it!

We previously had an $8k make up air system in the plans but we have decided to forego it and I officially give up now. I will just buy a good range hood insert, physically oversized to maximize capture area, and use at low CFM setting. In a super airtight home, we will need to open the window which can only do so much.

I don’t agree with anyone choosing recirculating range hoods in these modern efficient homes, a Passive House oversight, I am not an expert but it is complete nonsense. I totally see why someone would not want to deal with the headache associated with trying to ‘simply’ have proper kitchen ventilation. Nobody seems to know much or care much about this topic.

For the elite, proper kitchen ventilation it is certainly possible. Passive make up air dampers would require such a massive penetration in the building envelope though, I forget how big my engineer said it would need to be but it was enormous. Active make up air is absurdly expensive and conditioning it uses a lot of energy. We’re already spending many tens of thousands of $ on HVAC, how someone has not invented a realistic solution for this problem yet is confounding. Unfortunately, the average person has absolutely no hope of adequate kitchen ventilation. The most many can do is get a big enough hood with low flow, actually use it, and crack a window. I’ve once again started ranting. This was a great article but I think it should include the price of that fantech system.

Building science for poor people: best of luck, an apple a day keeps the doctor away!

My colleague says that where she grew up in Taiwan, the apartment buildings were totally unfurnished -- including HVAC. So a common approach was to have 2 kitchens-- one 'dry kitchen' inside for boiling water and such, and one 'wet kitchen' outside for cooking stinky stuff with lots of fumes. In other words, they bbq'd a lot and all year round. No makeup air needed there...

I know I know... Impractical. In my projects, it is imperative to have everything inside and puzzle about how to make it efficient and inexpensive

Just remarking on some anthropology

Interesting! You can see the problem when someone comes from that environment and is then forced to cook inside, for instance in an airtight modern home or apartment. I guess there are always peanut butter and jelly sandwiches, yum. For many cuisines, the kitchen heats up and smells up pretty quickly. Without proper ventilation because it is not at all within budget for 99% of the population, or access to outdoor cooking facilities, I don’t see a solution.

Well I certainly need an outdoor kitchen. A very ‘rustic’ one - not the kind with a gigantic TV and a ceiling fan. I think I can get behind the idea of year-round BBQ too.

Luke,

I used to go for meals at the houses of several Italian Canadian tradesmen who had two kitchens. One for show on the main floor, and another in the basement with access to covered areas outside where they stewed or boiled meat and fish.

Here on Vancouver Island a lot of people cook all their proteins on a barbecue, or outdoor burner.

It may have been the case for folks in rural areas, and in some buildings built before the 1980s (when I first arrived in Taiwan), few of which exist anymore. In contemporary apartment buildings, rough-out for ductless mini-splits, powerful (!) range hoods and bathroom vent fans are standard in Taiwan, where indeed most people live in multi-unit--mostly vertical--housing. When we moved to the States and built our "Pretty Good House," a Taiwanese range hood--despite its powerful draw--was something we couldn't live without. Interestingly, my wife--who is Taiwanese--grew up never having barbecued or cooked outdoors, is much less drawn to outdoor cooking than I am.

Interesting! I guess these people are surviving just fine without makeup air. I suppose if you don’t think of the horrors of depressurization, it is not so much of an issue.

So, what is your Taiwanese range hood like? What CFM? Do you have a make up air system? What is your air tightness? I was told we will probably need to crack a window just to operate the hood, I’m sure trying to operate it in an airtight house would drastically lower the performance and destroy the blower pretty quickly.

I surely think structures in Taiwan could be tighter, as cooling systems run for the majority of the year (even in the north of the country where the temp is over 70º for 9 months of the year.) "High performance" is not often discussed. Our range hood is a Pacific SC8130BS 900cfm unit. No makeup air in our case. Air tightness is "pretty good," though no doubt not up to the standard of a highly engineered house: good taping all around, Henry Blueskin, R-30+ walls, 18" blown-in cellulose attic, European 3-pane doors and windows, blower test numbers good, ERV, exhaust fan, dryer exhaust and stink pipe being the only penetrations. (Indeed, that dryer exhaust is a major weakpoint.) When the weather is milder, we're in and out alot and leave windows open. No performance issues yet after 4 winters here in Maine. If/when I do it again I definitely would wish to address the makeup air issue.

Interesting!! Yes my colleague probably dates to the pre 1980s era. Obviously it's second hand, and the anecdote clearly stuck with me

Ah yes, make up air. It may not be a difficult situation in Texas or Arizona, but I live in Anchorage Alaska and that winter make up air can be a bit frigid. I opted for cheap, simple and (hopefully) pretty good. My wood stove had a 4" proximity fresh air duct, which I upsized to a 6" with a manual damper(see picture). If I'm going to have excess cold air coming into the home, it seemed logical to bring it directly to the hottest spot in the house in the winter. How does it work? I wish I could tell you, but I am still building the cabinets so the induction stove and hood have not been hooked up.

Keep us posted on how it works! We're building in northern BC and just about to install a 4" fresh air intake for the fireplace and a 250 CFM range hood, no make up air. I assume it's safe to upsize the fresh air intake from 4" to 6", regardless of fireplace model?

I used to work in a facility with clean rooms and I would dearly love to have a laminar flow bench setup for the kitchen range, but alas, I need that money for a car rather than the flow bench. In my own PGH with an induction range, we selected a range hood with variable speeds from 100-700 cfm. We also have an oversize collection area located as close to the burners as we could. So with the fan on its lower settings, we really don't need much MUA, if any. But we do quite a bit of smoky cooking and I've been a bit of a hardass about using the fan when cooking. We will be installing a passive MUA system, venting into a cavity behind the fridge. In our heating-dominated climate I'm hoping that the generally cool or cold air will somewhat improve the fridge performance and also that the air will mix and dissipate a bit before coming into the actual kitchen space.

My $.02 about balancing: Since passive MUA doesn't do much until the house is depressurized, I think this works well for a kitchen. At lower hood flowrates, most of the MUA will probably come from the house. At higher flowrates, some comes from the house and some from the duct. In all cases the kitchen is slightly depressurized compared to the rest of the house, tending to keep cooking fumes in the kitchen.

After quite a bit of thought, I really don't like the TE2 approach for several reasons: primarily because the curtain of partially conditioned air is flowing down right over the cook and if the cook is uncomfortable, there will be significant strife in the household. So this means that the MUA must be conditioned up to room temp, and it takes a giant heating element to heat up the air at those flowrates. All of that energy then goes immediately up the chimney with the exhaust air. If using unconditioned passive MUA, the MUA will also eventually be heated or cooled, but if you are heating with minisplits, that heat is provided at a COP of 3 or so versus the COP of 1 for an in-line heater. I'm hoping that by allowing the MUA to trickle in around the fridge across the room, we won't be exposed to the worst of the very cold air in winter. We'll see. I'll let everyone know once we fire up the system in a few months.

Seems like a good strategy! How big is the damper though? I can’t remember what our engineer said but it was something crazy like 24” diameter required or maybe even way more. That being said a little bit of passive air is still going to be better than none!

It is too bad there is not a way to program an ERV to provide make up air somehow. Like if you could split the duct and operate dampers by a switch to provide all the airflow to one spot for a period of time. Maybe somewhere just nearby the kitchen. But there does not seem to be a way to get an ERV to supply air only without exhausting, maybe for a technical wizard it is possible. I think the solution will ultimately come from existing equipment though and not adding a bunch of additional expensive and space consuming equipment. But by this logic maybe it would be easier with an ASHP capable of higher CFM. Somehow control it to supply only to balance out the depressurization, and ideally isolated to one desired zone rather than the whole home.

The ERV can't run in supply-only mode because it needs the heat from the exhaust stream to keep the core warm. And, an ASHP doesn't supply any fresh air, only conditions the air already in the house. Therer are probably OK ways to introduce MUA using those systems, but the big problem with big range hoods is that, although for a somewhat brief time, they induce a huge air exchange rate. We spend all this effort to make a house tight and then we install not just a big hole, but a big hole with a fan sucking all of the air out of the house to be replaced by unconditioned outside air. There's no magic bullet here.

Take a look at the airflow rates we're discussing here. Just for fun, look at a 2000 sf house with a 1200 cfm fan. The house might have 20,000 cubic feet of total volume or so. 1200/20,000=.06 air changes per minute, or 3.6ACH. That's quite a bit for a house designed to leak at less than 1ACH50, with mechanical systems that can only provide enough conditioning for that flowrate. And somehow, some way, all of that MUA will be conditioned. In the TE2 approach, it's conditioned by a big-ass resistance coil that costs a bundle to install and even more to operate. With a passive MUA approach, it's more indirect but the mechanical systems will eventually have to take care of it.

In my case, a 100-200 cfm fan will work fine to remove typical cooking odors generated by my induction range - no combustion fumes, with a whole-house forced leakage rate of about .2ACH. That's not too much of an extra load on the HVAC. But when we need the higher speeds for smoky, greasy or otherwise stinky cooking, we've got it. When it's cranking in cold weather, the kitchen probably gets cold. But if we're driving the range that hard, there's probably enough waste heat to (partially) make up for it. Again, we'll see.

Peter,

I think this is a common dilemma that many of us face. We defaulted to the large commercial gas range with a massive 1,200 cfm hood in the design phase of our house because everyone does that. Researching make up systems, including the TE2 solution was pretty unsatisfactory as they all seemed to be expensive compromises in one form or another. To make things even more expensive, our local building department and inspector and would require systems to be designed by a licensed HVAC engineer with balancing calculations.

All this for something that looks great and costs a boatload of money but doesn't make better quality food. Came to our senses and went with a 36" induction cooktop with a 48" wide and 22" deep vent hood with a 600 cfm blower. No code or engineering issues. If we run it hard at full speed we can crack a nearby window.

Peter, thanks for the explanation! That makes sense. We need someone smart to solve this problem!

The least we can do is properly size the hood and try to choose one that is remotely close to being well engineered. The only ones that are properly designed as far as I’ve seen are commercial hoods. Containment volume is essential but not seen in residential hoods for an unknown reason… it’s just an empty steel box space, can’t imagine it would be expensive to include… but it’s easy enough to maximize the capture area and ensure the baffle area covers the cooktop and extends 3-6” on each side.

AC200 congratulations, you made a good decision. You are much better served with the smaller induction range and lower flow exhaust.

The blower CFM capacity of the range hood does not need to equal the desired air volume. In researching hoods for our house, I found that larger capacity hoods tend to have larger fans with much lower noise than "right sized" hoods (as well as lower static pressure due to larger duct sizes). Some of them also have internal settings to limit the maximum speed to 298 or 398 CFM to comply with codes for makeup air, preventing the homeowner from using them at their higher speeds.

IZZA,

We designed and built our own PGH about 6 years ago. No blower door test, but I know it's very very tight (when I open the door I can tell instantly whether any window or other door is open anywhere in the house).

MUA design for the modest range hood was a PIA but it has worked out, and is well worth the cost. Opening a window every time I cook something to me is not a practical way to live the rest of my life, and I don't want to be sucking air out of my attic or through my walls. I can't tell you the complete cost but I'm quite certain it wasn't anywhere approaching $8K! A bit of work by the electrician, some duct work and fan installation by our builder, and some equipment.

I couldn't get CFM figures from Broan for the various 4 speeds, but presumed it would operate commonly somewhere in the 250 cfm range or maybe below. Bought an in-line fan of around that CFM with a powered vent damper. Ducted the fresh air to dump into the pantry, which has its door directly below the minisplit, which will at least partially condition the MUA before it distributes. The electrician wired the range hood into a current-sensing switch at the breaker panel. Turn on the hood, the damper opens, then the fan turns on. On the lowest speed the house is under too much positive pressure, as judged by how outside doors open. Speeds 2 and 3 seem pretty neutral. Speed 4 gets us to negative pressure in the house. So we never use speed 1, always use 2 or 3. Speed 4 is too much exhaust anyway and is never needed, plus too noisy.

With air coming into the pantry, we have never ever felt it was creating cold draft in seating or working areas (Zone 5, border of 6). I feel certain there is no point in otherwise conditioning the MUA. Yes, Peter, there's no magic bullet.

A "disadvantage" is that the system turns on even if you only turn on the light for the range hood. However, this has proven useful for boosting airflow through the house beyond HRV exchange for coronavirus concerns when visitors come (combined with cracking a window open): just turn on the range light to get extra ventilation without the noise of the exhaust fan.

I looked into passive MUA, using a calculator on the Broan website: yes, it would take an absurdly large hole in your wall to make that work. Powered is the way to go.

I thought I heard a rumor a while back the Zehnder came out with a pressure-sensing ERV/HRV that would adjust input air to equalize output air when a range hood or dryer is turned on. Am I imagining things? This would seem to be the ideal solution.

Gahhh you are making me rethink this… I was SO set on needing the full system from the beginning. The costs are just astronomical. Our HVAC is like $70k so it’s possible the $8k MAU is just par for the course in an expensive market (southern Ontario Canada). Maybe I should talk to the HVAC contractor directly and see if he has any ideas. The engineer specified a Stelpro unit. But since deleting that we no longer have the physical spot it was going to go, so we’d need to find somewhere new to install it… and then remove siding to make a large hole in the envelope. It definitely seems like a hassle but hard to know how it’ll work without it. Drywall is going in pretty soon so I better figure it out. I also don’t like the idea of having to open a window in order to cook, especially on a -25C winter day.

I wouldn’t be surprised if Zehnder has that now! I feel like I also might have seen that somewhere, but I could have been dreaming.

Rethinking has to include asking whether make-up air is really necessary.

Just to throw out some hypothetical numbers, a 2000 square foot house with 8' ceilings that is sealed to an ACH50 of 3.0 has leakage of 800 CFM. It as an equivalent leakage area of 84 square inches, or equivalent to a 7x12 hole.

That's at 50 Pascals. 50 Pa is a vanishingly low pressure -- 0.00725 PSI. It's the pressure change associated with a six foot change in altitude -- walking up half a flight of stairs. This is not the kind of pressure that's going to cause your ears to pop or the trap water to be sucked out of your drains or doors to slam or windows fly open.

DC,

Beyond the problem of back drafting of combustion appliances, what are the consequences of (fairly temporary) depressurization? In our house, if we didn't have a wood stove we wouldn't know it was occurring - and I can't think of any other symptoms.

DC, have you ever been in a house undergoing blower door testing at 50 pascals? I know what the math says, but in practice you can feel air rushing through gaps and cracks.

I recently heard from clients with a 2200 sf Pretty Good House (around 2 ACH50) without makeup air that they notice a significant difference in how their 400 cfm hood performs whether or not they open a window. On another project, 2200 sf and 0.12 ACH50, when the 600 cfm range hood ran, even with a 4" passive makeup air vent, they found that the outswing exterior doors were difficult to open when the hood was running.

So let's look at the my hypothetical house from #30 -- 800 CFM, 84 square inches of equivalent leakage area. That's 13.3 cubic feet per second through 0.58 square feet, or a velocity of 23 feet per second which works out to 15 MPH. Yes, that's a noticeable breeze.

Let's add a 4" passive vent. Assuming no obstructions, that adds 12.5 square inches of venting, which is a 15% increase, with the same airflow that reduces the airspeed to 13mph. This is point one that I was trying to make with those numbers, even houses that are considered tight aren't submarines, they have leakage. And air goes where it wants to go, there's no way to force it to use the make-up vent rather than just the cracks in the walls. And for the most part the size of the makeup vents that are proposed really aren't that big compared to the leaks that already exist.

To Malcolm's question, the biggest impact that I can see is the exhaust fan potentially not working so well when there is back pressure. That is somewhat quantifiable if you have ACH50 numbers, you compare the CFM of the exhaust fan with the CFM from the blower door test and extrapolate the pressure drop. Then you look at the fan curve for the exhaust fan and see how much the CFM gets derated. 50 Pascal is about a quarter inch of water, which is the usual units for fan curves. Granted, hood fans don't normally come with a fan curve, you might have to ask a manufacturer, but looking at some for other devices they seem to run from 0.125 to 3.0 inches of water, so we're talking about the low end of the scale. And that quarter inch is for 800 CFM in a 2000 SF house, which is a lot of air.

As to the question of combustion appliances, Allison does a great service in the original article by quoting the relevant code section in full:

Where one or more gas, liquid, or solid fuel–burning appliance that is neither direct-vent nor uses a mechanical draft-venting system is located within a dwelling unit’s air barrier.

My feeling is you should be putting the makeup air at the combustion appliance. I've gone all-electric in my own home and I love it so I really don't see the need to burn stuff inside the building envelope anyway.

I have considered supplying powered MUA for the 1200cfm range hood in our planned kitchen through a concentric (ie double-walled) duct with the outgoing exhaust conditioning the incoming air as they pass by each other in opposite directions.

There are probably arguments both for drawing the incoming air through the outer jacket and passing exhaust air through the center duct or the reverse situation, depending on which orientation maximizes the heat transfer and how condensation from cold winter MUA is handled.

Has anyone seen a scheme like this used to condition incoming MUA?

There are "heat recovery units" for commercial kitchens. My concern with the concentric duct would be that there isn't enough surface area for significant heat exchange, and that by cooling the outgoing air, you'd condense the moisture and grease in the airstream, causing mold issues or a fire hazard.

user ...534,

The practicalities of the set up seem complex. I'm having trouble imagining both the inlet and outlet of the double walled pipe. Maybe I'm excessively risk adverse, but I prefer not to be the a first adopter of a strategy that has no track record. What is the back-up plan if it doesn't work?

I can’t reply to #33 above, so continuing here. Thanks GBA.

It seems dependant on the house based on what you’ve all said. A tighter and smaller home is going to have more of an issue without make up air, whereas a less tight and/or larger building might be able to get away with it. Not to hijack this, but in my case we have about 3,400 conditioned space and 3 levels, including walkout basement. Ceiling heights are 9’ on 2 levels and 8’ basement. Please lend your brains. We are aiming for 0.6ACH50 but haven’t done the first test yet. My builder mentioned another client who installed a similar range hood needs to open the window to operate it, probably a smaller house though. Maybe the hood could work, but I bet it’ll be super low CFM and will kill the motor.

My uneducated conclusion was previously that it might not be so bad since we deleted the wood fire and the home is now fully electric. The only direct venting is the range hood, bathrooms are just ERV and dryer is ventless. I don’t see the point in a passive damper, as DC mentioned I don’t see why the air would come through there rather than everywhere else at the same time.

So the one hood I’m considering because we don’t have much space for the inline fan and hood I wanted… is a Ventahood insert BH240PSLD. I thought I saw a fan curve somewhere but can’t find it now. Anyway, I am trying to decide between 350 CFM (which is apparently equivalent to 450 in a normal hood) vs. 600 CFM (equiv. To 900). My engineer said to look at the 0.2 wc pressure drop figure and get that where I want it at max speed. The “600” CFM is 480 @ 0.2 but I am not sure if that is what we would expect without make up air and with windows shut. My goal was to be able to achieve 400 CFM at high speed (actual), only used when needed, and generally operate during cooking ~ 200-300. Do you think it is reasonable to go with the 600 and try to use it at lower speeds? A top priority is silence, so I was thinking the dual blowers might be quieter to operate on low than the single blower on high.

"WC" is water column, 0.2 WC is 0.2" of water, which is 50 Pascal. Which is what ACH50 is measured at.

Let's say your house is 30,000 cubic feet, 0.6 ACH is 300 CFM. So if you achieve your goal during the blower door test the fan will be moving 300 CFM and depressurizing the house to 50 Pascal/0.2 WC. So a fan that achieves 300 CFM @0.2WC will be the same as the conditions of the test.

Now the fan you're looking at is rated for 480 CFM @0.2WC. Unfortunately there's not a linear relationship between pressure drop and flow, but what you can say is that in your house that fan will run at something less than 480 CFM and something more than 0.2WC. You also know it will run at something more than 300 CFM, because at 300 CFM the pressure drop would be 0.2 WC and you know it's higher than that.

It sounds like we should indeed install the “600” CFM dual fan hood then. Do you think the dual blower model (600) on lower speed will be much quieter than single (300)? The 300 CFM model is only 245 at 0.2” static pressure, 5.4 sones on high speed but they don’t list dBa. Whereas 600 is 480 and 6.5 sones. I don’t know if the sound is going to be linear, but my assumption is at equivalent flow the more powerful unit will be quieter.

OK, so are you saying that during the blower door test at 50 Pa, that would mimic the effect of a 300 CFM exhaust? I don’t know if they let people inside during the test, but if possible I could go in at least at the beginning and feel what would happen at 300 CFM exhausting? I have heard in another house they could feel air coming in through the outlets when the hood is running, so I assume we could feel the same during the blower door testing.

There are two claims for make-up air that I'd like to see more investigation of.

One is that by reducing the back pressure you're able to get more air movement. This is obviously true, but to what degree? As the discussion with Izzza points out, is there a reason this better than simply installing a more powerful fan?

The second is that the makeup air is somehow "better" than air than enters the house through infiltration. This is the point that Microbuilder makes in #24, "I don't want to be sucking air out of my attic or through my walls." I've also seen systems where the claim is made that by placing the makeup air distribution so that the cooktop is directly in the path between the makeup air and the hood, more of what the cooktop produces is caught by the hood.

What makes me skeptical of these claims is that even tight houses aren't airtight, and air doesn't move where you want it to move, it picks its own path. If you look at the size of makeup air vents that are typically installed, and the equivalent leakage areas of even tight houses, it's doubtful that even half of the makeup air is coming through the vent, and in many cases much less.

https://www.greenbuildingadvisor.com/article/passive-air-inlets-usually-dont-work

Providing any makeup air may be better than none to temper negative effects, but certainly a kitchen exhaust makeup air system should have a powered fan. A passive system seems like a good straw man to argue against.

How bad it is for air to infiltrate depends on climate, air quality issues, and open combustion appliances. It's bad for wood stoves (backdrafting). Air quality- my garage door is pretty close to my range exhaust- makes me worried that it could pull in car exhaust and CO through leaks or just if the door is opened. For climate, infiltration of very humid air could be a concern if there is prolonged very high humidity. The convection of humid air might meet conduction from the cooler inside climate.

All of these might not be a concern in a well-designed house. But they are also not a concern for makeup air- which does seem to make it a better option- whether or not it is worth the expense would depend on the budget and the particulars of the house.

graygreen,

Isn't this somewhat dependent on the CFM of the range hood? (which is an argument building codes seem to agree with).

A house with an electric range may do fine with a 200-300 cfm hood, which isn't drawing much more than two bath fans. In those circumstances I'm not sure powered make-up air is necessary in the way it seems obvious it is when the hood is one of those 1200 cfm monsters.

I think the code is concerned with back drafting and I agree CFM is all that matters there. It’s deficient in that it doesn’t add up the effect of the dryer, etc. for the other bad effects momentary CFM is not really the issue- it’s total CFM over time (and how that effects a particular house in a particular climate).

But it isn't costless. The question is whether the benefits outweigh the costs, or whether the same benefits can be achieved at a lower cost -- like by just installing a stronger fan.

"Infiltration of very humid air could be a concern if there is prolonged very high humidity. The convection of humid air might meet conduction from the cooler inside climate."

This assumes that the makeup air is conditioned, which is not the usual case and adds a whole extra layer of complexity. If the air is unconditioned then the makeup air is just the same outdoor air that seeps in through cracks and around doors and windows.

All of the concerns you raise still exist even if there is makeup air, there's no way to guarantee that 100% of the replacement air comes through the makeup vent and I'd wager that typically less than half does, and often far less than half. The only way to prevent that would be to positively pressurize the house with outdoor air when a vent is running. But the same infiltration still happens even when no vents are running. So shouldn't we be positively pressurizing our houses all of the time?

> This assumes that the makeup air is conditioned, which is not the usual case and adds a whole extra layer of complexity. If the air is unconditioned then the makeup air is just the same outdoor air that seeps in through cracks and around doors and windows.

No, not assuming conditioned. There's still a lot of differences. It avoids any potential problem of the outdoor air interacting with the wall assembly to cause moisture issues. We can avoid air quality issues (don't draw the air from the garage). The air can also also be filtered (we are assuming a powered fan). And a responsive system can avoid any backdrafting issues as well.

So all of the concerns I raised are addressed to some extent with a powered and responsive makeup system. I agree there will still be some localized air infiltration. But if you put the makeup air under the range like in the Home Performance youtube video I linked to prior, that should minimize local infiltration.

Should we positively pressurize the house all the time? The proponents of ventilating dehumidifiers take this position. I think it makes sense in the Southeast where there is lots of humidity and AC- it would help keep the wall assembly drier (and a little bit warmer because the AC isn't ran excessively to provide dehumidification). And you get the other benefits of mitigating some of the exhaust de-pressurization issues.

This discussion reinforces my decision to rethink MUA and switch cooking to induction. I had a detailed discussion with my local building inspector about the topic and he said would insist on a 1:1 MUA system for anything over 600 cfm even if the building code doesn't require it where there are no non-direct vent combustion appliances. When I asked him about the code he said something about a ministry directive that's been upheld on appeal (meaning good luck getting an occupancy permit)

Izzza, those Stelpro units don't seem to have enough flow even with a 12" duct for a large 1,200 cfm hood? I looked at large Electro and Fantech ones that were very expensive. The Vent-a-Hood "equivalent cfm" is marketing. They say their pressure drop is lower because they don't use baffles or filters so the performance at lower cfm is the same compared to a competitors hood at higher cfm. I have no idea whether that is true or not. What turned me off Vent-a- Hood was the grease cleaning. The thing is designed to fling grease droplets against the walls of the vent and then they flow down to a collection tray. The fan gets covered with grease and needs to be removed and cleaned regularly.

For the extra price of makeup air you could start looking at getting a Thermador Freedom induction cooktop- solves the issue of uneven heating due to small coils.

That's exactly what we did, with the "free" hood insert and external blower for buying the complete kitchen. The Freedom cooktop has reasonably easy to use controls for a digital cooktop

Would love to see your review of the cooktop- trying to decide if it is worth the premium. Particularly I am interested to know if it really does solve the uneven heating issue (coil to small) compared to standard induction cooktops.

We don’t need 1,200 CFM, the Stelpro was to match the exhaust around 450. From my research, I could be wrong, but ~ 450 (actual) is plenty for high speed in most situations. FYI, the Stelpro plus heater and install was around $8k in southern Ontario FYI. I believe it was a 10” duct.

I am mainly interested in the exhaust efficiency. For instance, installing a horribly designed hood with “1,200 CFM” might turn out to be like 30% efficiency. The problem I discovered is residential range hood design is all wrong. Not sure who is designing all this crap but it doesn’t appear engineers are involved. Number one thing I notice is people buy tiny hoods, not wide enough and not deep enough. Inadequate capture area followed by lack of containment volume as seen in commercial hoods. Then they never clean them if they have mesh, also people don’t use them if they are too loud. Wolf Pro makes a decent one with slanted baffles. For my case the problem is their blower, they don’t provide a fan curve or any information. They have a remote blower for the exterior of the house which I don’t want near our front door, or an inline fan which we can’t fit. The Wolf one would be easier to clean with baffles, but I’m fairly certain it will have more pressure drop because of this. With my goal of efficiency in mind, I want to use as little energy as possible to operate the hood and have it capture as much cooking effluent as possible and I don’t mind cleaning it. There is no free lunch.

What I like about Vent-a-Hood is the reduced pressure drop and quiet operation… yet to be seen! I watched this short video of cleaning, and it seems like a non-issue as far as I’m concerned. I don’t mind spending a few minutes wiping it out and a bit longer to do a deep cleaning once in a while, I doubt this has to be done super frequently unless you’re often deep frying on the cooktop. It’s just one of many household chores and the benefit is higher efficiency and less noise. Plus, in a world where we can outsource or automate so many chores now (i.e. roomba just keeps the floor clean all the time) it’s kind of nice to feel the house still needs a human to perform a maintenance task 😉

Also, an example of air not going where you want it to go as DC mentioned: look at a bad range hood. I am living in a condo while the house is under construction, I currently have an over the range microwave hood. It is laughably useless. It is so small and shallow, big plumes of steam and smoke simply rise around it. While the blower is on high speed, it captures a very tiny amount of the effluent because the air goes where it wants to go. Sure, it could be more powerful and try to suck up more of the sudden bursts but that will just further depressurize the space and use a lot of energy. I think it makes more sense to have a properly sized and engineered hood. The thing about cooking that I’ve noticed is that much of the time there is a small steady stream of effluent, which an extremely low CFM can handle just fine. But then there are massive bursts of effluent which even the most powerful fans would struggle to handle. Think searing a steak, opening the lid on boiling water, adding a splash of water to a fry pan. I think these events are equivalent to potentially thousands of CFM. So a 250 hood might be good for frying an egg, but let’s not delude ourselves to believe that it is going to do much if you want to cook burgers indoors.

This is over my head but I have a theory that using a higher power for a tiny moment in time, like turn it up right before you put a steak on or flip it, is going to use a lot less energy and cause less depressurization that running on low for a very long period of time including afterward to catch up. What will depressurize an airtight home more - 1 minute at 600 CFM or 20 minutes at 200 CFM? These numbers come from thin air, but I suppose my point is that using an inadequate range hood thinking it will prevent depressurization might not actually do so. By that time smoke fills your living space, it takes a long time to get that air back into the kitchen exhaust and then you’re depressurizing by exhausting mostly perfectly good air with a tiny bit of the polluted air. At that point I’m pretty sure a lot of particulate is just going to end up in your duct system and clog the very expensive non-washable air filters if you have them. Anyway, by this potentially flawed logic it almost seems like having a powerful hood (i.e. 1,000) is not necessarily the problem but rather user error is the issue. I think a powerful hood, usually used at like 250-450 but sometimes higher as needed, might make sense. Tell me, is this nonsense?

The power in a moment in time is what matters for several concerns:

* Backdrafting- which may be what code is most concerned with

* if someone is having trouble opening a door or a window

* the performance of other exhaust fans in the house decreasing

Total exhaust over time is a bigger issue for concerns about air infiltration.

Backdrafting is the only thing the code is concerned with.

One of the reasons I'm skeptical about make-up air is that the vent equipment itself seems to be completely unregulated and untested. Manufacturers can claim any CFM they want, and the makeup air requirement is based upon the manufacturer's claim, not any analysis of what might actually be delivered. And no engineering data is typically provided that would let you do that analysis.

So a fan that's rated for 1200 CFM but actually delivers 300 CFM when installed is treated the same as one that is rated 1200 CFM and delivers it.

And it's well-known that most range hoods aren't well-designed and don't do a good job of trapping contaminants. The code requires them, but says nothing about their effectiveness.

I remember looking at the $8k MUA system quote. I’m not paying over $10k for an unproven system with no guarantee it’ll work - a range hood that barely works and make up air that doesn’t even eliminate depressurization. If it all actually works perfectly as intended that is one thing, but the ROI is unproven.

Izzza,

I agree. You can sink a lot of money into these systems with little guarantee you will be satisfied by them.

We had a vent-a-hood single fan unit in a previous house and did not like it. It was an insert-style hood and we built a large box hood around it for best capture efficiency. The system worked fine to remove fumes, smoke and grease, but cleaning it was a serious PIA. Worse than that, the fan was very noisy. Before we sold the house, we switched to a Zephyr insert, not sure about which model. Loved it. Better baffle design and the baffle units can be cleaned in the dishwasher. Much quieter. We are going with another Zephyr (Monsoon Connect) in the new build. By using an insert and building the hood around it, the hood can be as big and deep as you want it. Lined with stainless steel or copper with wood outside, they can look pretty snazzy too.

Thank you so much for sharing, Peter! I am going to look into the one you’ve mentioned now since I was just about to order the hood… Also planning to do a liner insert but I am concerned about hating it because we will build a custom hood around it and it is looking very expensive so switching to another brand of insert after would be a hassle… I decided the ends need to be rounded with wood tambour, I was trying to think of a way to make the hood itself essentially cost as much as a make up air system and I’ve nearly figured it out!

So yours has an internal blower? That is what I was trying to avoid as I thought it would be very loud, but we don’t really have adequate space for a remote blower at this point. Interesting that you mention yours being quieter than the Ventahood.

Izzza,

"we don’t really have adequate space for a remote blower"

Have you considered the ones that mount on the exterior of the house and look much like an ordinary duct termination?

One example: https://www.broan-nutone.com/en-ca/accessory/336

Thanks for the link Malcolm! Yes, the Wolf Pro hood I like has an exterior remote blower option. We already installed the regular ductwork though, I suppose it could be swapped out? The Wolf exterior part looks similar to the one you sent, I don’t know if it would work based on the size and metal finish for where it needs to go. https://ca.subzero-wolf.com/en/wolf/range-hood/40-inch-pro-hood-liner-22-inch-depth

I’m not sure if it’s worth seeing if I should do this exterior blower option, or just go with the Zephyr one and hope for the best.

Izzza,

It's often hard to tell with fans how much of the noise is due to the motor, and how much is turbulent air movement.

I just got back from a walk to the beach. As cars came up behind me I realized I had trouble distinguishing between the gas and electric powered ones, as it was tire noise that dominated.

Good point Malcolm, I was hoping we could upsize the duct (thinking that would reduce noise from turbulence) but we didn’t have space so they just did standard. I think it’s 8” but it looked small to me so might be 6”. I’ll check next time but I think a 6” duct is a horrible idea here, I know very little and it seems clear that would be extremely loud.

Izzza,

Noise is the Achilles heel of all ventilation systems. It's by far the #1 reason they don't get used, or don't get used enough. It's particularly pernicious on a range hood because you then can't hear what you are cooking, and that's a problem when you are frying or grilling.

Thanks again for a great article and discussions !! It will take a while to wade thru it all.

BTW, it would be good to remind folks in all electric homes about depressurization hazards. You link to your previous article, but readers may not go there.

BTW, the previous article mentioned moisture, odor, and VOC intrusion from depressurization,

You should also mention soil radon and VOCs, and outdoor pollutants such as diesel vehicle emissions, wood smoke, and wildfire smoke.

Log in or create an account to post a comment.

Sign up Log in