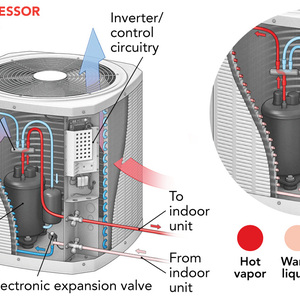

Switching from fossil fuel furnaces and boilers to heat pumps is a key strategy for reducing household carbon emissions. To maximize climate benefits, we need to minimize leakage of refrigerants, which are themselves potent greenhouse gases.

In a recent article, I discussed several strategies for mitigating refrigerant impacts. One strategy is to use packaged, aka all-in-one (AIO) heat pumps, with factory-sealed refrigerant circuits. Packaged units generally contain less refrigerant and are less prone to leakage than split systems with field-installed piping. In this article, I’ll look more closely at one available packaged system, the Ephoca AIO Wall Mount Pro, which is attracting interest as a solution for electrifying multifamily buildings.

Cold-climate AIO heat pump

The Wall Mount Pro is manufactured in Italy by Innova SrL and sold in the U.S. under the Ephoca label. The unit is on the Northeast Energy Efficiency Partnership’s (NEEP) list of cold-climate heat pumps, where it is classified as a “single package vertical heat pump (SPVHP).” Although SPVHPs are superficially similar to the packaged terminal air conditioners (PTACs) and packaged terminal heat pumps (PTHPs) often seen in hotels, there are important differences.

PTACs have uncased outdoor coils and slide into through-the-wall sleeves. In contrast, the Wall Mount Pro is enclosed in a cabinet that sits completely inside the living space and connects to the outdoors through a pair of openings.

While researching Ephoca products, I stumbled across a YouTube video featuring Evan Hallas, senior energy analyst at Taitem Engineering. Taitem is just a short walk from my house in Ithaca, and I’ve collaborated with its staff on several projects. I reached out to Hallas, who was kind enough to show me the system at Taitem and share his experiences with the product.

Hallas became interested in packaged heat pumps after reviewing…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

7 Comments

Jon,

Thanks for the write-up. This is what I have hoped for since I first saw the Medea window unit. The need for an dedicated HVAC installer, the complications and poor aesthetics of attaching lines between the indoor and outdoor units - and finding space for the outside one, all militated against mini-split adoption. The split units just felt like an interim, half-developed technology, while this one doesn't.

The COP is low though compared to the mini split. Is there something fundamental here due to having to access air through a fan or will that be improved?

Also not mentioned in this article is noise- this will put the compressor closer to people and presumably have noise levels similar to a window-mounted AC.

Sounds like an amazing product, particularly for certain use cases, but it seems like there will be trade-offs.

graygreen,

From Jon's write up:

"On the day of my visit, the unit had been taken out of operation, so I didn’t get to see and hear it running. The unit’s peak indoor sound rating is 41 dB(A). Hallas describes it as quiet and notes positive feedback from conference room users."

Thanks for the correction. No condensate as well!

So then it's really an issue of COP- only half the COP of the minisplit in some conditions. It's also twice the price but perhaps that gap can close a lot due to reduced installation and maintenance costs.

The ERV feature is neat but costs a stunning $2k for a small amount of CFM.

I'm hoping we see some significant cost reductions as production scales up and more companies enter the market. There's nothing inherently more expensive about the design. I'm hoping that we eventually see prices similar to the equipment costs of small mini split systems.

The efficiency issues are tougher. The fan power per Btu is going to be higher than in a split system because it's operating against static pressure. I suspect some small gains may be possible with larger ports (10" or 12"?), turning vanes, etc. The other issue is that the outdoor coils are tiny--they look like less than half what you'd see on a small mini split. There may be some incremental improvements possible with coil design, improved refrigerant metering, etc. It'll be interesting to see how this technology develops.

greygreen,

Yeah for me it's really when that reduction in efficiency is offset by the decreased complexity of the system. From my perspective, the closer it resembles an appliance the better.

Ephoca AIO sounds like a good replacement for my inefficient PTACs with weird dimensions, but actually getting my hands on one is kind of hard. Most HVAC/PTAC companies don’t sell it, so I would have to order one directly from Ephoca. The catch is that retail sales are limited to whatever is available in their USA warehouse at the moment I place the order, so I cannot get the exact configuration I want. The alternative is to go with their recommended contractor and their price ends up being twice that of a mini split (professionally installed).

Log in or become a member to post a comment.

Sign up Log in