To continue last week’s discussion of heat-loss calculation methods, let’s consider a simple rectangular building, 20 feet by 30 feet, with 8-foot ceilings. Let’s assume it has an 8-foot-high basement with uninsulated concrete walls; the below-grade portion of the basement is 7 feet high, with 1 foot above grade.

To keep things simple, we’ll assume that the house has a flat roof, and that each side of the house has two windows (each 3 ft. by 4 ft.) and one door (3 ft. by 7 ft.). The house doesn’t have a chimney.

We’ll assume that the building is in Boston, Massachusetts, a location with an outdoor design temperature of 9°F. That means we have a ΔT of 61 F°. Let’s calculate the expected heat flow rate per hour through the floor, walls, and ceiling at the design temperature. (For the time being, we’ll ignore infiltration.)

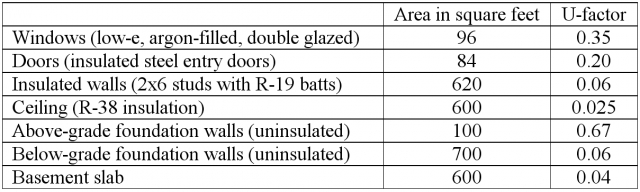

First, determine the relevant areas and U-factors

The first step is to group all of the envelope components with similar U-factors together and calculate their areas. The second step is to look up or calculate the relevant U-factors.

The listed U-factors for these assemblies are subject to discussion, and some readers may dispute whether the chosen values are appropriate. For the time being, however, let’s leave that discussion aside and use these U-factors to illustrate the calculation method.

(Tables listing U-factors for a variety of building assemblies can be found online; here’s one of them. The original I=B=R table of building assembly U-factors can be found here. Almost all of these tables are subject to dispute. If you prefer, you can calculate your own building assembly U-factors by adding up the R-values of the relevant layers and converting these R-values to U-factors, using the equation U=1/R. Click here to read more about calculating the U-factor…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

45 Comments

Heat loss to ground

When I was building the heat loss model for our new house, I used a spreadsheet to tabulate and tally the U*A numbers for all of the above grade wall sections, windows, doors, and attic floor. Calculating areas and making sure I hadn't missed anything was tedious, of course. Similarly, I had a few lines in the model to account for heat loss due to expected natural air leakage and for loss from mechanical ventilation after HRV efficiency was figured in. Still, within the limits of how well the various R and U values would actually match reality, those parts of the heat loss were fairly well defined.

What always bothered me was that the heat losses through the basement slab and below-grade foundation walls were a lot harder to define. This is not for lack of information on R values to use, as both slab and concrete walls had R20 of XPS foam for insulation. It was the delta T to apply that was the problem.

An uninsulated slab or foundation wall will lose more heat and tend to warm up the soil against it than if it is insulated. While warmer soil reduces the temperature difference across the concrete, does the combination of concrete and mass of soil around it present a higher effective area for heat transfer? Clearly, heat loss through an insulated slab or wall will be lower than through an uninsulated one (and the insulated slab or wall will provide much greater human comfort). Clearly, too, a dry and sandy soil will be less conductive than a wet tight soil. While some 3D models have been presented to show what soil temperature profiles look like for various cases, it seems to me that selection of soil temperature adjacent to a slab or wall section, insulated or not, is rather hard to define for heat transfer purposes, and that the corresponding entries in the overall heat loss model will be the most inaccurate of the model.

In the end, I just played with some assumptions, to see how the overall model total was affected. For the insulated slab, I assumed that the heat loss would be so low that the soil below it would be close to the deep ground temperature. For the below grade wall sections, I assumed a linear temperature profile, going from outside air temperature at grade to 32 F at three feet down (footers had to go down to four feet below grade), then linear from there to deep ground temperature at slab level. It was the best I could do, but I always felt that there had to be a better way to define ground losses.

I tend to rationalize away the lack of accuracy in the heat losses to ground when there is plenty of insulation by telling myself that knowing those losses better won't affect the bottom line significantly or change the selection of heating equipment size.

Response to Dick Russell

Dick,

You bring up an important point: describing and quantifying heat loss through below-grade basement walls, basement slabs, and slabs on grade is enormously complicated, even for academic energy researchers.

Here in Vermont, below-zero temperatures in early December can drive frost deep into the ground, especially when the snow cover is thin. In other years, we can have two feet of snow on the ground in late November before the thermometer drops below zero, and the ground never freezes all winter long.

The moisture content of the soil affects thermal conductivity, and ground water movement can play havoc with one's assumptions. Many of these factors can be bracketed but not measured precisely. In short, whenever we perform heat-loss calculations, we need to be humble.

Darn it!!!

First you tell me to dust off and oil my sliding ruler, now that it’s done, you tell me this calcs are too complicated and sugeest to leave it to a professional… this is just too much stress… ARGHHHH!!!

Response to Armando Cobo

Calm down, Armando -- I'm not done yet. This is part 2 of a 4-part series.

It's useful to know how to perform simple heat-loss calculations, and sometimes it's a good idea to perform them yourself -- with a spreadsheet, or with a pencil and a pad of paper -- with or without a slide rule. (If you are a big fan of the I=B=R pencil-and-paper method, I didn't leave you high and dry. All the details you need to use the method can be found in the original 1951 document that I linked to.)

There are times, however, when it makes sense to use a Manual J software program.

Finally, it's useful to remember that either method (by hand or with a computer program) can sometimes result in an inaccurate answer.

So:

1. You need to know when to use a certain tool.

2. You need to know the limitations of the tool you are using.

3. You need to know when available tools are unnecessary -- because some tasks don't require heat-loss calculations at all.

Lubricating your slide rule was not a waste of time. The next time to talk to a teenager, you can always demonstrate how engineers used to perform calculations before the invention of electronic calculators.

Response to AJ

AJ,

As Michael Blasnik says (paraphrasing Albert Einstein), "Everything should be made as simple as possible, but no simpler."

Simple is good. I introduced the I=B=R method to explain some fundamental principles -- not because I believe that the method should be frequently used.

Stay tuned for more on the topic of simplicity and heat-loss calculations in upcoming blogs.

I think their is a much

I think there is a much simpler approach. It is called experience. The last two residences we used what we learned here, and the knowledge of three associated pros, the drafting company had built many low energy homes, the insulater had, and the HVAC company was asked to install small.

We kept to the basics and the performance has been outstanding. Well, the new basics as this site has been the source for, thank you GBA.

Our present PGH basics;

-Solar orientation

-Continuous superinsulation

-50G electric water heaters- foam insulated, better but not expensive, self limit overuse, best ROI value

-Better HVAC condensing single speed, two zone- next will look into two speed.

-Panasonic bath fans for ventilation- Looking into overide CO/moisture controls, for now they are on with bathroom use, makeup air enters HVAC ducting, Riversong bedroom vents option.

Anyway, building homes one after the other gives all of us the best local data for any home style or size or orientation.

Still GBA should put up on this website a GBA sponsered version of Simple energy software. Or Martin whip up a Martin version of Simple and your I=B=R just do something to improve it for oversizing results and larger home errors.

Response to Dick Russell & Martin Holladay

The colder the subsoil & climate, the more important it is to model the basement heat losses reasonably, but for most of the lower 48 heat loss below the 100 year frost line is "in the noise", smaller than the typical error in the rest of the calculation, even with uninsulated slabs. At code-min insulation levels slab losses can pretty much be ignored from a heating system design point of view (but not necessarily from an energy use point of view.)

The Canadian Hot2000 building energy use simulator (similar to DOE2, in function, if not detail) does a reasonable job of it, but that too tends to overestimate- too many simplifying factors to the heat loss model. The PassiveHouse tools do an even better job, but the site testing & engineering required to fill in the data accurately can more than just adding another R25 of sub-slab EPS, making an accuracy that serves no practical purpose (and well beyond the scope of a heat loss calc for HVAC design purposes.)

Dick's simplyfing assumption that with an insulated slab (any R value) that the average temp under the slab is effectively an infinite heat sink at the deep subsoil temp would overestimate at low and moderate Rs and under estimate at higher Rs, but in both cases the size of the error is deep into the "who cares" noise. In anything but a super-insulated house, for heating & cooling design purposes I'm comfortable with using that simplifying assumption even in an uninsulated slab, and simplifying the model of the slab & first foot of soil as ~R2. It can be off by as much as 50% either direction depending on site & soil factors but is of little consequence from an HVAC design point of view- the gains/loss totals of rest of the house usually dominate that error factor by more than 2 orders of magnitude.

BTW: Harold Kestenholtz (a hydronic design instructor) released a commercially availble I=B=R heat loss calculator some ~30 years ago, and currently offers up a freebie download version, available here:

http://www.heatpro.us/

http://www.livepast60.com/heatpro/estimation_programs.htm

I haven't used it and thus can't vouch for it, but it's probably as good as any other IBR tool.

Foundation heat loss

I do not have it in front of me but the ASHRAE Fundamentals Handbook has a manual calculation for foundation heat loss that is easy to use. It deals with depth of foundation, slab perimeter and I believe, soil type. A manual heat loss calculation for buildings is a good exercise to help understand how heat loss is apportioned. With this information, energy upgrades can be considered by isolating particular building elements.

Response to Dana

Dana said: "In anything but a super-insulated house, for heating & cooling design purposes I'm comfortable with using that simplifying assumption ..." Actually, the house is a super-insulated one. In the final energy model, the numbers for slab and buried foundation walls accounted for almost 17% of the total, so I did indeed give a fair amount of thought as to the validity of that number. I do agree, however, that a simpler allowance for ground losses probably is adequate for an ordinary new house, where other losses dominate by far.

I adjusted the model every time I made significant changes to the design of the shell. Early on, the bottom line told me that I'd be uncomfortably over the capacity of a two-ton GSHP. After fiddling with the design some more, including some changes to slab and foundation wall insulation, but without going to Passivhaus extremes, I got the total down to where it was comfortably below two tons. Even so, while I told the HVAC sub that he should size the ductwork for three tons, and the well already had gone to a depth that would support over three tons, I waited until after the first blower door test to firm up the selection of the two-ton unit.

It's interesting that earlier estimates from three others, all done with software and based on information I provided about the details of the house as it stood when my numbers showed somewhat over two tons of heat loss, all indicated a need for a five-ton unit. From the details of one of those calculations, I saw that the bulk of the extra tonnage was due to air leakage that was way off the mark. I am guessing that all three had similar errors. I remain convinced that doing a good calculation for a superinsulated house is either outside the capability or beyond the willingness of most HVAC contractors to spend the necessary time to get it right.

Coming off the first heating season, I have some very limited performance information on the new house. First, as far as I can tell, the heat pump never had to go to second stage to keep the house at temperature. Of course, this winter was a fairly mild one, overall. Still, there were some nights that dipped to zero or slightly below for a short time. This tells me that the heat loss model was either right on or, more likely, overestimating the heat losses. As far as cost goes, by subtracting out KWH used for a "typical" shoulder season month from each bill since mid-fall, it seems that the heat pump electric cost will come to less than $500 for the season. This is for a house on two levels with a footprint of about 2,000 sq.ft. I am installing an hour meter on the heat pump to collect better information on usage for both heating and cooling. I'm happy with the way the house has turned out.

Response to Doug McEvers

Doug,

Fortunately, Chapter 28 of ASHRAE Fundamentals is posted online: ASHRAE Fundamentals Chapter 28.

The foundation heat loss calculation method that you are referring to is detailed in that chapter.

Dick Russell, more

Dick Russell, more information

For the GBA readers;

KWH price

Location, heating degrees

Solar orientation

HP total install cost.

Lastly, how do you now value HP systems, comfort, noise, temp setback, register exit temp, etc.

Couple items for Dick R

It is amazing how much some contractors will oversize systems. Going with somewhat upsized ductwork pays back in reduced blower power as well as providing headroom for installation problems.

It is a simple matter, if you are moderately handy, to connect a pair of Readington LCD hourmeters to the Y1 and Y2 control signals (low and high stage) going to the heat pump compressor section.

Another thing that caught my attention is 6 GPM - pumping that much water from a deep well at 40 psig is likely using a significant fraction of total system energy input. You might trim that a bit, particularly in low stage.

Perhaps, especially with judicious removal or adjustment of some flow restrictors, domestic water pressure could be further reduced to 25-30. The geo system only needs about 5 psi.

I'm looking forward to a discussion of cooling loads, latent and sensible.

Great job, Dick Russell

Dick,

Using your numbers, the Btu/sf/hdd is .81, you have built a very efficient house.

$500.00 @ .14 kWh is 3571 kWh for heating or 12,185,714 Btu's. Divide this by 2000 sf and 7,500 hdd is .812 Btu/sf/hdd, excellent!

ACH and exfiltration

I've read articles by Lsitburek explaining that simply doing a blower door test to determine the ach @ 50 Pa only tells you a characteristic of a house. It doesn't tell you where the holes are, or the distribution of the holes, or the pressures acting on a house at any given time, and in short doesn't tell you the actual rate of exfiltration at all. (or whether or not you need mechanical ventilation to supply fresh air) However, if you have done a blower door test, and you know your ach @50 for instance, can you use that information to create at least a better estimate for what your exfiltration rate might be for your heating load calculation?

Also, if you have mechanical ventilation what is the easiest pencil and paper way to calculate that heat loss if you can know that specific exfiltration rate? Or perhaps that is for an upcoming blog post.

Thank you Dick

Thank you Dick Russell!

Please add to your post above the well cost so I can remove it from your HVAC cost since your well cost was the cost of your domestic

water cost.

Martin, Dana, Dick, Doug, Curt, you guys are sharing info that all of us contractors need. Missing info, false claims are useless. This thread is one of the most useful threads at GBA!

Malcolm, your post it right on. Blower doors are telling one thing which in some cases may mean nothing! Basically good for finding the leaks. That is good. Then one has to use there head and decide what to do about each leak.

Ten years of being on the GEO fence

Ten years of being on the GEO fence and not buying coming to an end. Today is the first day I have heard the positives I needed to hear to feel ready to sell GEO to a prospective customer. Dick, you are in my climate zone and you have built a home others should be sold. Great job my man and thank you for sharing details.

Info on the house for AJ

The location is Moultonborough, NH. I've seen all sorts of numbers for heating degree days for my location, ranging from around 7000 to over 8000. Based on some maps and data for the state capital (Concord, 30 miles south), somewhere around 7500 or more seems like a decent average, although recent years have seen this slip lower.

Electric power here is provided by the NH Electric Cooperative. Price has been around $0.14/KWH on recent bills. I should have noted that in the heat model I did not take any credit for normal electric use for appliances, lighting, hot water usage; all of the first two are energy that winds up within the house, and a fair amount of the heat in hot water is recovered as it goes through piping within the house enroute to the septic tank.

The site has very limited solar opportunities, due to a lot of trees all around and a steep hill to the west. There are two south-facing windows that pick up a little heat in winter.

Total install cost for the GSHP, including well, HP, duct work (3 zones), and controls came to about $37K, before any rebates and tax credits. The heat pump by itself was about $9K, with the Climadry feature (Climatemaster Tranquility 27). [Edit 4/29/2012: see later post for more detail and corrections.]

I think the selection of ground source heat pump was a good one for this situation. The design heat load was going to be very small. A well was going to be drilled for domestic use anyway, and likely was going to be deep enough to support at least three tons just to get adequate water flow. That's the way it turned out; no extra drilling was needed for the heat pump capacity (only two tons).

Unless I look at instrumentation, the only way I know the system is running is if I am close enough to hear the water rushing through the piping at six GPM. The unit itself is hardly more noisy than a refrigerator. I just can't hear any air rushing sounds from the ducts. There was some water noise transmission through the floor system, which I fixed by better hangers for the supply and return piping (that went overhead to avoid floor level piping to trip over), and some through a flow control device, which I fixed by taking some pressure drop through system isolation valves. I recently dropped the house water pressure from 50 to 40 psi and that helped a lot.

In first stage, the heat pump puts out air at around 88-90 F; second stage, if I ever see it come on, provides 99-100 F, according to the tables. There is electric strip heating, both 1 KW for third stage and 5 KW for emergency heat; the breaker for electric heat has been off anyway.

I don't set back at night. It's just left at 70 F for the main zone. For a house like this, setback would be almost of no benefit, since it loses heat so slowly. Moreover, given the small size of the heat pump, regaining a couple of degrees from being off all night would take too long for me. We do leave the thermostat for the zone covering two bedrooms on the upper level set way back, as we like it cooler there for sleeping. I don't think that zone ever comes on, as that zone doesn't seem to want to drop below 65 in winter (if we keep the bedroom doors closed), due to heat leaking in from adjacent space.

One final comment: I do think that having built a detailed heat loss model for this house was very important for proper selection of the heat pump size. Any changes I made to get the unit size down to two-tons certainly didn't cost more than the difference to go to three tons. I may even have saved a small amount overall, as some of the changes included reduction in size and number of those triple-pane windows. Several of them were either too big or unnecessary anyway, once we thought about it. If the model had said I needed a three-ton unit anyway, I may not have made any further changes to the house shell.

Updated GSHP info; BTU/sqft/HDD

AJ, I have added a note to my last post on this thread (#12), pointing to this post. I was working from memory on the installation costs, so I dug up the detail, which I needed to collect for the IRS geo tax credit. Here is the way it breaks down.

All costs associated with the well, including drilling, casing, lines to/from the house, minimal inside plumbing to point where plumbing contractor takes over, the pump and controls. The well contractor used an 8"casing rather than a 6" one, as they had to have a second pitless adapter for the return line. There was also some extra material and labor associated with the return line. Bottom line for the well contractor: $16,823.

HVAC contractor charges, including the heat pump and associated parts and installation, ductwork and controls for three zones and thermostats, but not including the HRV or range hood ducting and related costs. Total for these costs: $24,021, of which $10,550 was for the heat pump unit and related parts for its installation.

Plumbing contractor charges for connecting heat pump to lines to/from the well, including isolation and bypass valves: $890.

NH Electric Coop rebates: $ 2,100.

IRS geothermal tax credit: $11,890.

Total rebates/credits: $13,990.

Doug, from what I could find about heating degree days, this past season has run about 17% below normal, so figure 6300 HDD. Also, that 2,000 sqft has two levels, so that gross conditioned space is 4,000 sqft (do we subtract out wall, closet, stairwell areas?). Using these numbers, that figure you had for BTU/sqft/HDD probably is more like 0.48. But that's sort of cheating on the numbers, as half the lower level is buried into the hill and doesn't lose much heat.

Dick, exact facts and figures

Dick, exact facts and figures are the only figures that inform. Thank you again.

Response to Malcolm Lewis

Malcolm,

Q. "What is the easiest pencil and paper way to calculate that heat loss if you can know that specific exfiltration rate?"

A. Here is the formula (it is often used to calculate heat loss due to mechanical ventilation):

Ventilation heat loss (in BTU/h) = Ventilation rate (in cfm) ● ΔT (in F°) ● 1.08

[The last factor (1.08) is the volumetric heat capacity of air in BTU ● minute / hour ● cubic feet ● °F]

Response to Dick Russell

Dick,

Thanks very much for sharing your cost information; I'm sure GBA readers are interested. The bottom line is that your ground-source heat pump system cost $41,734 before rebates.

I'm sure that your system is energy-efficient, but in light of the system's cost, I think the jury is still out on whether such expensive systems are a wise investment.

Martin, all homes need water.

Martin, all homes need water. The GEO cost was to me closer to 30k for a 4,000sqft project. That sells me and I am anti GEO.

The bottom line for me is a Dick Russell home is a home some in the Adirondacks will be building.

Martin, I do agree of course that there are other choices.

Btu/sf/hdd

Dick,

I have always used outside dimensions for this calculation, including walls. Basements are included, all levels, building line x number of stories.

Your house is very efficient at 2,000 sf, twice as good at 4,000. There is the matter of GSHP efficiency and the conversion factor involved. I use the meter readings for my calculations and I believe you should as well. However, if you had electric resistance baseboard in your house as the heating source, the kWh would have been higher for the heating season and with it the Btu/sf/hdd.

Response to Jon Pierce

Jon,

You wrote, "IF the english is hort to thought phrases, too short? Stop. And ask what... please!"

My head horts. I don't know if that's because the phrases are too short, too long, or not English.

Btu/sqft 5500-6600 dd 73-80 Td

Great to read!

IF YOU HAVE A Q) at any point, just ask at that point for amplified commentary...

IF the english is short to other thought phrases, too short? Stop. And ask what... please!

Dick and Mark I posted a positve + click at your comments b/c detail (aj- yes) informs[informs us nicely].

[About those], and Calcs? (engineering is foundational). and

getting back to Dick [who I agree with that many wont do the study of limits, unless beat over the head by tutors I ran too in Calc at UC to get a 4.0 that I did then]

Everything [regarding a SIMPLER line by line heat load study, and only if multistaging equipment is not applicable to a very detailed heat load study of more than 10 minutes in heating dominant bhildings usually] -- it all STILL needs to be simpler for a 7th grade educated great marketing and sales person who can be essential to closing deals [ bucks are lost to 1 hour home studies sometimes... the masses buying GT and Heat Pumps to day are many where one needs closer to 96% accuracy and speed, respively, in regards to Dick.]

What I mean is [ as from 4 years at U.Cinci Colg Engineering Sciences, 3.85 at a best year] I thought I was all things to all people, until I read more, very much later. [this is typical of an A/E or analytic, we get our blinders on and sometimes forget to ask "where does it hurt"... ]

Mark [to you and all]

I like it all [evry bit you explain, and well put for ME]

the info a lot [what you wrote]

and look forward to the rest! And you DO sell yourself very well for an audience, being more fair to readers than I yet have..[ youo are complimented]

Dick:

Here is what I did:

I watched how the solar guys in selling came up with space heating calcs for a 30% space-heating, non-storage Air Solar system. Their heat load sheet for quick ~ 96% to 100% accurate calcs was what I attach here. or can send you for 10 miniute studies. PROVEN EFFECTUAL EVERY TIME. Some of the most personable 7th grade educated folks that close sales can handle the X'xs and +'s and but will not be any less pro than a calculator that we see in any full engineering requirements.

Here the sheet is a VIEW of 80-dif and 73F-diff design; and as my excel worksheet that I adjust for the locality. -Starting by first asking if money will go to improving the building. (Changes may prompt 2 studies, as a reference, you will see.)

Then based on existing bills,

guessing HVAC efficiency, in regards to those bills (rettrofits), then

asking about DOES IT CYCLE on the hottest/coldest days, -about what you now use for the HVAC?

Further:

Checking / questioning cold-day air leaks (what's been found.by the owners, if retrofit..) I finish the envelope study, or can use for a room, study with SURFACE AREA GUESS at tightness and ventilation (COMPARING CFMx1.08xTd design=BTU's as Mark says) and multiply all the roof and exposed walls as a whole x .8 to 3.5 btu/surface sq ft.

It is too like an art including by (my) EXPERIENCE with electric furnaces running in zero degree weather that at other temps, showed me air infiltration is not linear with the loading at 5 above to 10 below, not at all- especially in looser structures. Infra red compounded the accuracy corollation(s).

The surface area calcs work very well. They were identical for equipment selection guesses made by other blog "pro"'s that I recently read.

Like a structure under cold water trying to press in, that guess for air infiltration is plenty close for new and old. Mark's leading us to the ART of the experience will be read several times by me.

multi-zone equipment source sizing: With Dual compressors, variable, etc, sometimes has been dominated by just : --How fast do want to heat the water? -If the HW is made by some form of 2-to-say-4-tons w:w systems contributing to cooling , then cooling may be as little as 1/3 of the final compressor selection, also requiring NO supplemental heating in MANY cases at all for GeoThermal with HW On-demand as an oversized desuperheater, to W:W separate 2nd units (or from an ONLY ONE W:W UNIT and more for the plumber.)

hort = short, a little slower now.

hi

in complements of your work and trying to explain in an edit it tripped a "spam switch" so here:

a) thanks for you and the writ.

b) aj seems accurately addressing informed is by calcs, too

c) Dick is correct also acknowledging simplicity required, as it takes a real genius to achieve at times (Einstein stated)

d) I address HW by AIR, past and present.

e) not so concerned with a burst to POE, as a liability, until you or one can explain ...

f) Mentioned HW by GT units were sold since the 1980's - can detail, if one wants

g) Notes about tremendous success I have had in HW-HVAC-GT Full condensing IN COOLING MODE, where circulators to loop are completely off-line in ~ 100% "INSTANT" HW during cooling, as well as being a large HX coil in Desuperheat modein heating, and On-Demand, all from a third , a larger HX coil in a single unit...

h) or get a W:W gt comparing to AIR:HW standups, or combos.

Also companies like Aquacal, St Pet Fla have sold AirHtP HW for spas for years, and others, and do so really well in the north

HW HtP: older heat loss x air infiltration significant figures

hi MARTIN:

Great reading Mar correct air infiltration calc'g!

How HW is managed can relate to :

One of the reasons a surface area of all building exposure in stick homes and heat dominant buildings (more usually 2-3 story on occaision is "good enough" is based on a factor I use for training for quickly deciding in 80 and 73 design diff, 6600-5500 deg days - a cost DIFFERENCE from a single compressor- single speed: a multi-stage 2-staging, or a multi-speed-3 and 4th staging compressor combo system:system. An inexpensive thermometr is great for precise temperature differences. JUST THE SAME is with discussing for the sale, discussing the dollars adding up to a different combination of single and/or dual compressors. It is understood there is a big leap from a 60k compressor in a "size 6.0" to 75k found in "Size 7" 's or 80k-84k compressors found in "size8.0" boxes-- but from 2.5 tons to 6.0... differences in same size compressor to a combo of the same compressor tonnage begins to drive the design with a buyer, before closing a total VALUED System installation.

Any. home improvements LATER wont change the differential until about under 2.1/2 tons or over size 6's, for many of the home prospects/suspects.

2)

Accurate air infiltration by blower door results as a % of the whole, with expenses, how large is that with regards to what may be off set by sizing compressor(s) for DHW demands desired rather than say a cooling size in a heat dominant space condition? - I am trying to relate this to not to just look at a DHW as a system separate from any HVAC possibility. I am told regular large AirHtP make HW and in Cooling mode too , and beyond small 9000-12000 btuh desuperheating.

Glad to see more!

Horting in the Adirondacks!

Horting in the Adirondacks!

Discophonous cognitive dissonance at its best

Or the a new Cheney "enhanced interrogation protocols revealed"?

Part 3 and 4

Hi Did part 3 and 4 ever get written? If so can you reply with the links. I can't find them.

Thanks

Response to A. Lange

A. Lange,

Part 3: Calculating Cooling Loads

Part 4: When Do I Need to Perform a Load Calculation?

Great article, as usual, but the characters in the formulas are horked / mojibake.

“[Deleted]”

Could you kindly explain the symbols in this formula:

Exfiltration heat loss = Room volume × ΔT × ACH(nat) × Infiltration factor

Are those subtractions symbols between the 4 terms in the equation (these symbols: — )?

I don't understand what ΔT à means. ?The product of ΔT and à ?

Thanks very much.

Those symbols should be delta (Δ ), meaning change.

Thanks, Michael. When Taunton moved my blogs to a new web platform (Wordpress), the new platform couldn't handle unusual symbols. I hope I've fixed the problem. I appreciate your help.

I still cannot understand this formula:

Exfiltration heat loss = Room volume × ΔT × ACH(nat) × Infiltration factor

I cannot figure how how to calculate exfiltration heat loss. I am guessing that what appears as an A with a tilda over it should be a delta symbol. In each case, that squiggley A symbol is followed by what looks like an extra long minus sign. What is the latter sign.

BTW, the links no longer work. For a newbee like me, I am clueless as to what I=B=R refers to and the links do not work. Thanks.

Ruth,

The strange symbols you have copied in your comment were an artifact of a computer translation program that failed to handle Greek letters. The formula you copied does not exist. I have corrected the article on this page; refresh your computer browser to see the latest version of this article. You should see different formulas that include the delta symbol (Δ). "Delta T" or "ΔT" means "temperature difference."

I have also corrected all dead links so that the current version of the article should have links that work.

It's best to read my three-part article in order, starting with Part 1. The first part of my three-part series introduced the I=B=R method of heat loss calculation. Here's what I wrote: "Thirty years ago, heat-loss calculation methods were fairly unsophisticated, especially when it came to air leakage. I first learned how to perform heat-loss calculations in 1975, using a pencil and a paper form called the “I=B=R Calculation Sheet.” (This method was promoted by the Institute of Boiler and Radiator Manufacturers, an organization that no longer exists.)"

The second article further explains the I=B=R method, which is simply a paper-and-pencil way to calculate heat loss. (The Institute of Boiler and Radiator Manufacturers had a peculiar way to spell their abbreviation, using the equal sign between the three letters.)

The article on this page (Part 2) includes links to the original I=B=R documents.

Here are links to the three articles:

How to Perform a Heat-Loss Calculation, Part 1:

https://www.greenbuildingadvisor.com/article/how-to-perform-a-heat-loss-calculation-part-1

How to Perform a Heat-Loss Calculation — Part 2:

https://www.greenbuildingadvisor.com/article/how-to-perform-a-heat-loss-calculation-part-2

Part 3: Calculating Cooling Loads

https://www.greenbuildingadvisor.com/article/calculating-cooling-loads

ok, thanks so much. Now that this link works, I can make the first calculation: http://www.ci.brainerd.mn.us/building/docs/heat_loss_calculation.pdf

For this formula: Exfiltration heat loss = Room volume × ΔT × ACH(nat) × Infiltration factor, I am assuming that the ΔT is the difference between the HDD in my area and 70 degrees? (The ΔT symbol previously looked like Ihat"T.)

Using fuel usage in January and making an assumption about the therms in fuel oil, I calculated that (using the 1.4X sizing recommendation), I need 51,300 BTU/hr with the 65 degree set point, and 55,300 with the 60 degree set point.

Now I want to see if I come up with a number in the same range when I use the other method of calculating heat load.

I live in northern New England. Would love to convert to a heat pump.

Continuing my estimations, I used this worksheet (www.ci.brainerd.mn.us/building/docs/heat_loss_calculation.pdf) and estimated my Sensible Total Heating BTUH loss. As I understand it, this represents the heat loss per deltaT. I am understanding that there are two additional steps. One is to multiply by deltaT and possibly to account for ductwork not in the heated space. The other is to estimate exfiltration losses.

Question 1: Which of these steps should I do first (I will later calculate cooling).

Question 2: My understanding is that the units of the Sensible Total Heating BTUH loss are BTU/HrXdegree. What are the units of the exfiltration losses calculated as explained in the post above?

Thanks again very much. I still have more to do and more questions but I want to get this straight in my mind.

Ruth,

You have the wrong definition for delta-T. You wrote, "I am assuming that the ΔT is the difference between the HDD in my area and 70 degrees?" No.

The delta-T has nothing to do with HDD (heating degree days).

Here is what I wrote in Part 1 of my series: "The difference between the outdoor design temperature and the indoor design temperature is the ΔT (delta-T)."

Read Part 1 to get a definition of the outdoor design temperature and the indoor design temperature.

“[Deleted]”

I am confused about exfiltration.

I calculated heat losses and heat gains using this worksheet: https://web.archive.org/web/20120913015331/http://www.ci.brainerd.mn.us/building/docs/heat_loss_calculation.pdf

I also used this calculator: https://betterbuiltnw.com/hvac-sizing-tool

The calculator estimates heating: 74,000 BTU/hr ; Cooling 24,000 and 2,500 latent. This is not far from my calculations from the worksheet.

My understanding is that this does not include exfiltration. Is that correct?

Even if I assume that my house is tight, I calculate that exfiltration will add 30,000. That would seem to mean that I need a very large unit.

Any advice on this would be very much appreciated.

Can you show your work?

Heat loss is difference in temperature times air flow in CFM times 1.08. So if it's 0F outside and 70F inside, you'd need about 400 CFM to get 30,000 BTU/hr. That's a lot of air, you'd hear it whistling through cracks in the building.

Thanks for your insight. I am enclosing some of the output from the HVAC sizing tool. My impression is that this does not include exfiltration. I will recheck my exfiltration calculations and post them in a short while. I do not think I hear wind whistling through the building at low outside temperatures, so I may not be understanding how to make the exfiltration calculations.

Let me show my Exfiltration calculations for the upper floor of my house, perhaps you can see where I am going wrong.

Rooms that have windows and/or doors on one side total 561 square feet. With 7.5 foot ceilings, the volume of these rooms is 4207 cubic feet.

4207 X 73 (from outdoor design temp of -3) X 1 X 0.018 (leaky bldg)= 5,528

Rooms that have windows or doors on two sides total 458 sq. ft, with 7.5 ft. ceiling, the volume of these rooms is 3435 cubic feet.

3435 X 73 X 1.5 X 0.027 = 10,155

Foyer is 56 sq ft. with 13 ft ceiling, so a volume of 728 cubic feet

728 X 2 X 0.036 = 52

5528 + 10,155 + 52 = 15,735

If you see a poor assumption or misunderstanding, I will correct this and will explain more about the lower floor.

Thanks again so much,

Ruth

Log in or become a member to post a comment.

Sign up Log in