UPDATED on January 25, 2018 with information on phenolic foam.

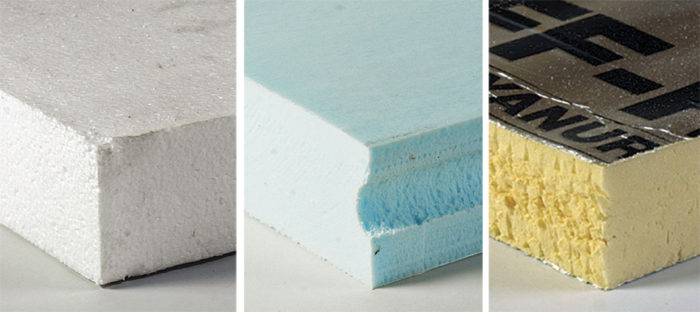

Maybe you’ve decided that your floor, wall, or roof assembly needs one or more layers of rigid foam. Which type of foam should you choose: polyisocyanurate, expanded polystyrene (EPS), or extruded polystyrene (XPS)?

The answer depends on several factors, including your R-value target, your local climate, whether the insulation will be in contact with soil, and your level of environmental concern.

R-value per inch

Manufacturers of insulation products are required to provide consumers with R-value information. If you’ve purchased rigid foam insulation that isn’t clearly labeled, contact the manufacturer to learn the product’s R-value.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

- The R-value of EPS ranges from about R-3.6 to R-4.2 per inch. In most cases, the higher the density of the EPS, the higher the R-value per inch.

- The R-value of XPS is R-5 per inch.

- The R-value of polyisocyanurate is R-5.7 to R-6 per inch (although cold-climate builders sometimes use a lower R-value because polyisocyanurate performs poorly at cold temperatures).

Over a period of decades, the R-value of polyisocyanurate and XPS gradually declines. For more information on this phenomenon, called “thermal drift,” see Thermal Drift of Polyiso and XPS.

Cold weather performance of polyiso

Rigid foam manufacturers are required to perform R-value tests using an ASTM method specifying that the test be performed at a mean temperature of 75°F. At lower mean temperatures, EPS and XPS perform better than their R-value label indicates. In other words, as the temperature drops, the ability of EPS and XPS to resist heat flow improves.

Polyiso behaves differently: as the mean temperature drops, it does a worse job of resisting heat flow. For that reason, some cold-climate builders assign a lower R-value for polyiso — perhaps R-4.5 or R-5 per inch — than the R-value on the…

…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

32 Comments

Global warming impact

As I pointed out shortly after Alex Wilson wrote that article on the global warming impact of insulation, he used a whole lot of assumptions to come up with his conclusions. I don't consider that article to have much validity. Here was my response back in 2010:

Don't Forget the Science in Building Science

The ABC's of GWP for XPS

From the link that Charlie posted from the XPSA: "All of the blowing agents currently used by the

industry have a life cycle positive benefit, as measured by greenhouse gas emissions." So if I use it to make a super-insulated birdhouse, it'll have life cycle positive benefit in terms of green house gases? Or if I use 10 inches of it...below grade...in Houston, it'll have life cycle positive benefit in terms of green house gases? To refuse to acknowledge that there's a threshold for each application where the application is no longer life-cycle positive is disingenuous.

Charlie - do you have a link to more information on the phase-out of HFC blowing agents in North American XPS? It certainly could be good news...

no question

The fact that XPS and ccSPF use high GWP blowing agents in the US is well known and admitted by the industry. For example, here is a statement from the industry association that is quite clear and direct about it.

http://www.xpsa.com/pdf/01%20-%20XPSA%20Industry%20Perspective%20on%20Sustainability%20and%20Environmental%20Awareness.pdf

The good news is that HFC blowing agents are scheduled to be phased out in XPS [edit: by Jan 2021--I said before "in 2017 IIRC." but IDRC--see below.] Unfortunately, there is no corresponding agreement on ccSPF, but, good news again, Lapolla has a low GWP "4G" product already available, using HFO blowing agent.

Phase-out of HFCs

The EPA SNAP program "Rule 20" has the schedule. Here's the fact sheet:

http://www.epa.gov/sites/production/files/2015-08/documents/snap_regulatory_factsheet_july20_2015.pdf

and the full rule:

https://www.gpo.gov/fdsys/pkg/FR-2015-07-20/pdf/2015-17066.pdf

You can see in these documents that polystyrene extruded sheet has a deadline of Jan 1, 2017; Polystyrene extruded boardstock and billet has a deadline of Jan 1, 2021. The trick is figuring out whether the stuff we use if buildings is sheet or boardstock. It's boardstock, so the data is 2021. From the full rule:

"• Polystyrene (extruded sheet) includes foam for packaging and buoyancy or flotation.

• Polystyrene (extruded boardstock and billet) includes insulation for roofing, walls, floors, and pipes."

Perhaps some insulation manufacturers will start differentiating their XPS by transitioning sooner. It's already the case that Owens-Corning pink foam uses a lower GWP mix than Dow blue foam, but only by a factor of 2, not by the factor of 100 to 1000 that we will get by 2021.

There's also work on an international agreement, with a rule under the Montreal Protocol to be finalized in 2016. http://yosemite.epa.gov/opa/admpress.nsf/6424ac1caa800aab85257359003f5337/c489a7d31ef941ee85257ef50049921d!OpenDocument

Beware of polyiso sheathing - a sponge around your house

Thanks Martin for another great article! As you noted, polyiso foam board absorbs water -- unlike XPS and EPS. If you wrap a house with sheets of foam board, there will be many edges and joints, just waiting for a trickle of water. With polyiso, each large sheet can turn into a large sponge. With perfect flashing, sealing, housewrap, etc, no problem, of course. One mistake by a sub could equal a big sponge, however -- with a reservoir of moisture to encourage rot.

Mark

Mice?

What about rodent resistance? Do these three all have the same RR value? I seem to remember mice having a whale of a time in XPS insulation.

Response to Mark Hays: "A sponge around your house"?

Mark,

The hypothetical situation you worry about -- "With polyiso, each large sheet can turn into a large sponge" -- is highly unlikely, and in fact is one that hasn't been reported on GBA. Nor is this situation one I have ever seen. Nor is this situation one that I have heard about at any building science conference. It sounds like a scenario invented by EPS distributors or XPS distributors.

GBA recommends that builders who install polyiso on the exterior side of wall sheathing also install vertical furring strips to create a ventilated rainscreen gap (unless the polyiso measures 1.5 inch in thickness or less and the siding is vinyl siding, which is inherently well ventilated). If these recommendations are followed, the rainscreen gap will be dry -- in fact, this will be one of the driest parts of your house. The siding keeps off almost all of the rain, and the ventilation air encourages evaporation. Sunlight contributes to the extraordinary dryness of a rainscreen gap.

A builder would have to be extremely sloppy with his or her flashing details -- criminally sloppy -- to end up with the type of scenario you describe.

Response to Bruce Lepper: "Mice?"

Bruce,

In my experience, using rigid foam does not result in more problems with mice. Mice are far more likely, in my experience, to live in fiberglass-insulated cavities than in rigid foam.

The best way to reduce rodent infestations is to pay attention to airtightness. The lower your blower door number, the less likely that your house will have mice. Mice like holes -- that's how they enter your house. If you seal your holes, the mice will (generally) stay outside where they belong.

GBA readers who have encountered mouse nests in rigid foam are invited to post comments here. I have lots of tales about mice in fiberglass-insulated walls... but most GBA readers are familiar with that problem.

Response to Mark Hays

Mark,

Your wrote, "I have seen a number of cases where water traveled under and into a wall assembly, particularly in colder climates, e.g. via backed up gutters with rotten fascia or water dams on the edge of the roof."

So have I. Have you ever seen damage like that in a house with a ventilated rainscreen gap?

The polyiso sponge

Dear Martin:

A rainscreen will certainly help, but I have seen a number of cases where water traveled under and into a wall assembly, particularly in colder climates, e.g. via backed up gutters with rotten fascia, water dams on the edge of the roof, etc, etc. I am sure other builders have as well. If these leaks reach polyiso, it will absorb the moisture literally like a sponge -- and remain damp for a long time. With virtually identical R ratings and pricing, I would not increase the risk for a customer or myself with this product in exterior applications. Polyiso is great, however, for interior insulation.

I have no connection to any building supply manufacturer, by the way -- except as a customer.

Mark

Rigid foams absorb water - full stop

I am disappointed that GBA is still purporting the myth that rigid foams do not absorb water in a below grade or below slab application or even on a roof applications. This is far from accurate. If water is present, these boards wet up. EPS absorbs moisture very quickly but may dry faster between wetting cycles if spaced far enough apart and installed over gravel so that it can dry. XPS wets up much slower than EPS but still does wet up over time, but also dries at a much slower rate. My own testing showed a 250% mass increase in EPS due to wet up and a 31% for XPS over a 8 month test. (http://thepathtosustainableliving.blogspot.ca/2014/08/sub-slab-insulation-eps-vs-xps_31.html) And ask any building envelope remediation firm and they will confirm that they have pulled saturated samples of both types out of roof assemblies and plaza decks.

Response to Sean Wiens

Sean,

GBA has consistently advised readers to include drainage systems for every foundation. All of our details show drainage systems.

Moreover, when rigid foam is installed on walls, the wall assembly should usually include a ventilated rainscreen gap between the rigid foam and the siding.

Finally, when rigid foam is installed above roof sheathing, it needs to be covered by roofing. When roofing fails and begins leaking, you have a problem that needs to be addressed immediately. Many types of insulation will be degraded when faced with a roof leak -- and roof sheathing and framing lumber are also at risk when roofs leak. So by all means, fix roof leaks promptly.

So if your point is that rigid foam absorbs water when it is allowed to sit in a puddle or a pond, I agree. So don't install rigid foam in a puddle or a pond.

Drainage systems for foundations include a layer of crushed stone (drained with perforated piping) installed under horizontal rigid foam, and free-draining materials (or a dimple mat) adjacent to foundation walls. These systems will help maintain the R-value of your rigid foam.

Below Grade still wets up

Martin - thanks for response.

The point is that foam does absorb moisture and your posting "XPS and most types of EPS are rated for ground contact. These products can be buried without worrying that the materials will lose their insulating value or absorb significant quantities of moisture." did not have the caveat that you have now included in your comment above.

Of course if you remove the water source it probably cannot absorb moisture (I will be doing long term testing below slab in my upcoming build - but there is a suspicion that even in high RH environments, the foams will wet up).

Re foundation walls, how often do you see the backfill right up against the foam without dimple sheet or any form of drainage plane? All the time?

regarding roofs : plaza decks and inverted roof assemblages often use rigid foam. These systems by their nature have the foam exposed to moisture. These systems do wet up.

So again the point is that these foams do absorb moisture and when discussing their use, a strong recommendation to include drainage plane should always be included in the same sentence.

Response to Sean Wiens

Sean,

Over the years, I think that my advice on this topic has been consistent. See, for example, these two articles:

All About Basements

Fixing a Wet Basement

My advice in those two articles is almost identical (yes, I tend to repeat myself). I wrote:

"If you are building a new home on a basement foundation, you should specify ... a layer of dimple-mat drainage board installed on the exterior side of the foundation walls; failing that, the foundation should be backfilled with coarse, free-draining material like crushed stone, topped with an 8-inch layer of dirt (ideally, dirt with a high clay content)."

Thanks Martin

Thanks Martin - I was only reacting to your article above which stated "XPS and most types of EPS are rated for ground contact. These products can be buried without worrying that the materials will lose their insulating value or absorb significant quantities of moisture." and did not include the caveats that you have now mentioned in the comments. Every article that discusses rigid foam below grade needs to include the warnings that the foam does wet up if water is present.

How can one reliably identify 'type II' EPS on the used market?

Martin, I would like to follow the GBA advice to seek reclaimed ~4 inch EPS here in MA for my underslab project. However, I am finding that many people offering such foam rarely indicate attributes such as PSI rating which makes me think that manufacturer markings are not typically stamped onto the full sheets. How can I reliably determine from picture or in-person inspection whether it is type II? I understand that many walkable roofs will use Type II, so that might help if the seller knew where the material came from. Can I run a simple strength test using a vise clamp or such? Thanks for all the pertinent advice on this site.

Under a 4" slab it doesn't really matter (@Kenneth Gardner)

Almost all used EPS from reclaimers is Type-II or denser. It typically comes without facers (although some has a heavy facer on one side to withstand the heat of torch-down roofing a bit better). It's fairly stiff stuff at 2", and isn't easy to poke a finger into (but fingernails, yes). Lower density Type-I often has lightweight facers, and with a facer peeled back it doesn't take a martial arts black belt to poke finger in 1/4" or more, but it's not particularly squishy the way some ultra-low density packing foam can be. Type-I foam without facers is easy to scar up, and corners are often dented or broken in handling.

The most reliable method is to weigh it: Type-II EPS has a minimum density of 1.3lbs per cubic foot (3.5lbs per inch of thickness for a 4x8 sheet) and a nominal density of 1.5lbs per cubic foot (4lbs per inch of thickness for a 4x8 sheet.) If it's been sitting out in the rain for months/years it can theoretically have some amount of additional water weight stored in the interstitial spaces between the beads, but that would be rare. If it's been exposed to too much sun it's surface will be chalky/dusty from UV degradation of the polymer, but most reclaimers keep it under tarps or in sheds.

You can't tell anything about it's density from a picture.

But unless the foam is under a footing, even Type-I foam doesn't present a problem for a 4" slab.

XPS vs. closed cell spray foam concerning environmental impact

I am contemplating the different preferred methods for insulating a low pitch (2/12) metal roof in our next custom home that we haven't started. I have read through many of the GBA articles on the subject of vented vs. unvented, R board above roof sheathing with closed cell foam or loose-fill insulation below, etc.

I had settled on the "unvented option - R-15 r board (two 1 1/2" layers of XPS) above sheathing with blown cellulose below over the spray closed cell foam for environmental concerns. (We are in the 4A climate zone) We have used the spray foam insulation method in many projects, but want to make sure we are building homes as energy eficiently as possible, with the least amount of environmental damage. I understand that this, along with many green building issues, is highly debatable, but is there a definitive way to determine what is more harmful to the environment, the production of XPS or the use of spray foam?

Thank you,

Scott

>"I had settled on the "unvented option - R-15 r board (two 1 1/2" layers of XPS) above sheathing..."

At 3" XPS is only warranteed for R13.5 (read the fine print), and as it's climate damaging HFC soup diffuses out over a handful of decades it will gradually drop to R12.6, the same as 3" of EPS of similar density. But what the heck- maybe by the time that happens global warming will have moved you to zone 3A (?).

Not a good plan.

4" of Type-II EPS is blown with a variant of pentane with a low ~7x CO2 global warming potential, most of which escapes the foam and is recaptured at the factory. It's performance would be R16.8 on day-1, and would still be R16.8 on day 25,001 (68+ years later).

Foil faced polyisocyanurate is also blown with low-impact hydrocarbons, and at 3" would be labeled R18, and would still be delivering R15+ performance over time.

Fiber faced roofing polyiso would be labeled R17 @ 3", and would also be delivering R15+ decades later.

With just R15 above the roof deck there is only enough dew point control for (R49 - R15= ) R34 of fiber insulation below the roof deck and still meet the IRC prescriptives. That would be about 9.20" of cellulose. A 2 x 10 rafter bay is nominally 9.25" deep, so it's pretty close. But a 11.25" deep 2 x 12 rafter bay filled with cellulose would deliver about R42, which would then require R15 x (R42/R34)= R18.5 above the roof deck.

The environmental impact of closed cell polyurethane blown with the industry standard (and Kigali amendment contraband) HFC245fa is almost as bad as XPS. If blown with HFO1234ze the impact is comparable to 2lb fiber faced roofing polyiso, but still roughly twice that of 1lb density foil faced polyiso.

Bottom line, go with 3" polyiso (any density) in your climate & application.

Dana,

Thanks for your response. I get what you are saying regarding the environmental impact of the different foam options and that all makes sense. However, regarding performance, doesn't the above article suggest that polyiso isn't the best option during cold temperatures?

"Cold weather performance of polyiso

Rigid foam manufacturers are required to perform R-value tests using an ASTM method specifying that the test be performed at a mean temperature of 75°F. At lower mean temperatures, EPS and XPS perform better than their R-value label indicates. In other words, as the temperature drops, the ability of EPS and XPS to resist heat flow improves.

"Polyiso behaves differently: as the mean temperature drops, it does a worse job of resisting heat flow. For that reason, some cold-climate builders assign a lower R-value for polyiso — perhaps R-4.5 or R-5 per inch — than the R-value on the product label."

I realize that we aren't in the coldest climate zone, but we do experience equally harsh winters and summers. I assume that you are suggesting that the foams' performances in hot temperatures are more important than in the cold temperatures, but not sure. Not trying to argue, I'm just trying to clarify the information.

Thanks again,

Scott

Just say "no" IMHO.

Is there any info on GBA regarding the expansion and contraction characteristics of XPS and EPS? Is one more preferable to the other in cold climates that see large temp swings between winter and summer?

PVO,

Q. "Is there any info on GBA regarding the expansion and contraction characteristics of XPS and EPS?"

A. Yes. See the article titled "Using Rigid Foam as a Water-Resistive Barrier." Scroll down until you find the section with the heading, "Do rigid foam panels shrink?" (The discussion of this issue continues for several paragraphs below the heading.)

Hello,

I have a 1940s 1.5 story Cape Cod w/ 2x4 rafters in Portland, OR zone 4c. We recently gutted the attic and will be replacing the roof and are hoping to insulate as best we can. I think I’ve read every GBA article on insulation and know what I’m supposed to do, but reframing w/ larger rafters is out of the picture, and adding >2” of exterior rigid polyiso to hit code required r49 will cause too many problems with detailing.

We did however talk to a roofer about installing 2” of exterior polyiso with 3.5” of mineral wool in the rafter bays, or ~ (2” * r6) + (3.5” * r4 * 0.8) = r23. The roofer said don’t bother with the rigid foam - it wouldn’t make a noticeable difference, and to put the savings into an AC.

Is this true? Thicker is of course better, but is r12 rigid still worth it? With diminishing returns on the high end, is there also a threshold on the low? Is there a sweet spot to aim for between cost and performance? Or does this installer just not want to deal with rigid foam?

Thanks in advance, and so appreciate what you guys do.

Jared,

Q. "Is this true?"

A. No.

Q. "Thicker is of course better, but is R-12 rigid still worth it?"

A. Yes.

Q. "With diminishing returns on the high end, is there also a threshold on the low?"

A. No.

Q. "Or does this installer just not want to deal with rigid foam?"

A. You guessed it.

Would be great to see GPS (graphite polystyrene) insulation added as an option to this article; to educate any readers who aren’t aware. With its enhanced environmental footprint (no blowing agents) and excellent performance characteristics. That’s what I ended up using on my own build; but isn’t that well known sadly.

Thanks for the tip about GPS, @Andy_C. Doesn't seem to be easy to find -- any tips on sourcing it? Appears that BASF makes Neopor, then the Neopor product gets used to make rigid boards with different trade names.

In the PNW, the product I often specify is Insulfoam Platinum GPS. I think they have had some COVID supply chain issues with getting the raw materials for GPS from BASF, but my local rep (you can find your rep here: https://www.insulfoam.com/find-a-rep/ ) has been pretty responsive in terms of figuring out what is and isn't available and how to get it. At the end of the day, I'm not the one actually making the orders, and I don't always know what the contractors we work with actually buy. Hope that at least gets you started!

As a side note, my insulfoam rep (Dave Haug) was recently very helpful in tracking down some equivalent structural values between their geofoam products and regular EPS products, which made me a fan.

Thanks, that's helpful. Unfortunately, the closest reps to me are Florida and Nebraska. Ooof.

Up here in rural Maine I feel like we're often a decade behind on innovations like this. Maybe I can push the envelope a little.

Hey! So I’m based in BC, Canada. The product is called Chrome GPS that I used. I believe it’s manufactured in Ontario, which really isn’t too far from you. There’s a great company based out of Edmonton called Performance Haus who may be able to ship to you. There will be other distributors I’m sure like Beaver Plastics, and ProgressiveFoam.com looks like it’s US based.

Can anyone please advise on using Foamular 250 over the concrete slab vs foil faced EPS? Foamular has a little bigger r value but I’m wondering if it has more permeability.

Foamular is XPS; it is rated at R-5 per inch but over time it will drop to around R-4.2 to R-4.4/in so it's only about 10% better than EPS in that regard. It has much higher greenhouse gas emissions, even the newer formulations sold as low-GWP. Foil-faced EPS is not vapor-permeable, due to the foil. 1" XPS is roughly 1.1 perms; 2" is somewhere around 0.5-0.6 perms.

Log in or become a member to post a comment.

Sign up Log in